Crack Detection

Eddyfi Technologies for Cracking Inspection Applications

Aging infrastructure found in the power generation, petrochemical and industrial sectors are subject to cyclic loading and fatigue stress, resulting in a physical response of cracking in materials or fixed equipment being exposed to damaging conditions.

Details

Aging infrastructure found in the power generation, petrochemical and industrial sectors are subject to cyclic loading and fatigue stress, resulting in a physical response of cracking in materials or fixed equipment being exposed to damaging conditions. One of the most prevalent defects, cracking comes in various sizes and shapes from surface-breaking cracks to high temperature hydrogen attack (HTHA) cracking.

Fatigue Cracks

Fatigue cracking is one of the main damage mechanisms of industrial assets. The combination of cyclic stress below the ultimate tensile stress or yield stress of material like corrosion, temperature, overload, metallurgical structure and residual stresses results in fatigue cracking. It ensues in three stages: 1) crack initiation, 2) stable crack growth, 3) rapid fracture. Because the only indication of an imminent fracture is a hard-to-see crack, fatigue damage is particularly threatening.

Stress Corrosion Cracking

Stress corrosion cracking (SCC) can lead to an unexpected failure of normally adaptable metal alloys jeopardized by a tensile stress, frequently at higher temperatures. It is a growing crack formation in a corrosive atmosphere and highly chemically specific. Stress corrosion crack mechanisms can take various forms, such as intergranular SCC, transgranular SCC, or interdendritic SCC. It often progresses quickly and can impact materials in different ways from dry cracking to catastrophic failure. It is prominent around welds, the heat affected zone (HAZ) and base material in storage tanks, pressure vessels and process pipes.

Amine Cracking

Amine cracks are a form of stress corrosion cracking appearing on the surface of pressure vessels, boilers, and piping systems with radially projected cracking from their set-on nozzles.

Ammonia Stress Corrosion Cracking

Ammonia SCC is common in brass tubes with a cooling water function that have been polluted with ammonia due to biological growths or other impurities.

Chloride Stress Corrosion Cracking

One of the most recognized forms of SCC, chloride stress corrosion cracking appears as highly branched spiderweb cracks. External chloride stress corrosion cracking (ECSCC) is a type of corrosion under insulation (CUI) that appears in austenitic stainless steels.

Carbonate Cracking

More threatening at high pH and high concentrations of carbonate solutions, carbonate cracking is a form of alkaline stress corrosion cracking (ACSCC) prevalent to oil and gas production, chemical processing and petroleum refining industries.

Wet H2S Cracking

Wet hydrogen sulfide service environments like refineries suffer cracking in exposed carbon steel equipment. Wet H2S cracking can form without warning and requires advanced NDT techniques to be detected.

Hydrogen Induced Cracking

Hydrogen induced cracking (HIC) is wet H2S cracking in steel in the form of blisters or blister cracks. HIC damage is a common degradation mechanism in the oil and gas industry. There are NDT techniques focused on identifying, measuring and tracking HIC, but Total Focusing Method (TFM) has shown to be generally the preferred technique.

Stress Oriented Hydrogen Induced Cracking

Stress oriented hydrogen induced cracking (SOHIC) consists of blister cracks connected through the thickness direction by transgranular cleavage cracks. It is more severe than HIC as it dramatically diminishes load carrying capabilities of materials.

High Temperature Hydrogen Attack Cracking

High temperature hydrogen attack (HTHA) cracking occurs in steel when exposed to high temperatures and pressure, appearing as bubbles that join to produce micro-fissures at steel grain borders. The reduced metal strength causes cracks to form in steel. HTHA can result in failure of critical equipment including exchangers, piping, welds and catalytic equipment.

Thermal Cracks

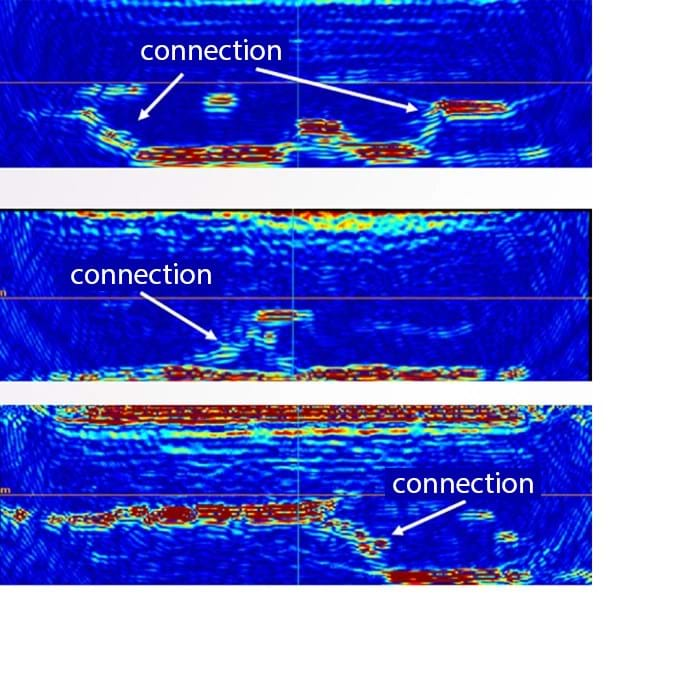

Thermal cracking can be the result of excessive temperature variance. It can be found in the piping sections of cooling systems, for example. For the power generation sector, thermal fatigue cracking can be attributed to specific operating conditions, and line geometry (e.g. elbows and connections).

Branched Cracking

A fracture mechanics problem, branched cracks occur when a critical constant velocity is paired with a critical stress intensity. Clusters of connected cracks, branched cracking appears in unstable breakage of brittle materials and as SCC in strong steels.

Non-Destructive Testing for Cracking

Regular inspections of industrial equipment throughout all production phases and during their service life represent an important part in avoiding asset failures. They assist facility life management and component fitness-for-service assessment of aging plants. Crack detection is the process of detecting cracking, usually through non-destructive testing (NDT). Early detection enables preventative action to mitigate potential failure and ensure operations efficiency. Different NDT methods are used for the detection of cracking in pipelines, storage tanks, pressure vessels, or other capital assets. Rough surfaces, paint or other types of protective coatings add to the challenges associated with surface inspection for cracks. The ideal NDT approach may involve one or a combination of techniques to provide a comprehensive dataset on structural integrity of critical components.

Surface Detection of Cracks

Eddy current testing (ECT) and eddy current array (ECA) offer fast inspection of surface-breaking cracks, often with only minimal surface preparation, if any. Users can collect a digital record of their assessment and measure the depth of surface breaking cracks - direct advantages over PT and MT. Eddyfi Sharck™ probes are designed specifically for cracking in carbon steel using tangential eddy current array (TECA™) technology. These probes position, measure and size cracks through paint or other protective coatings. Other standard ECA probes detect and size cracks in stainless steel materials, for example. ECA probes work with Eddyfi Reddy®, the first portable instrument that unlocks surface inspection for a range of new applications. Designed specifically for stress corrosion cracking, the Eddyfi Spyne™ is an adaptable surface ECA screening tool that leaves no crack behind with high speed, Probability of Detection (PoD) and efficiency. When it comes to surface detection of cracks, eddy current testing is ideal.

Alternating current field measurement (ACFM®) is an electromagnetic technique that was originally developed in the 1980s to address fatigue cracking issues faced by oil and gas companies in offshore structures. The technique specializes in in-service inspection of both underwater and topside structural welds, regardless of whether they are ferromagnetic or non-ferromagnetic. It offers the advantage of providing fast scans on coated and unprepared surfaces, while also generating detailed electronic records of detected crack locations, lengths, and depths. This valuable inspection data is essential for making informed decisions regarding asset integrity and optimizing repair strategies.

Over time, the use of ACFM has expanded to various other applications. For instance, the Amigo2 ACFM instrument can be equipped to inspect generic structural welds, OCTG drillstring threads, galvanized steel components, underwater structures, and components operating at temperatures up to 500°C (932°F). This versatility further showcases the broad applicability and effectiveness of ACFM in diverse inspection scenarios.

Volumetric Inspection of Cracks

Phased array ultrasonic testing (PAUT) has been recognized as one the best inspection techniques for volumetric inspection of cracks. It is efficiently used for finding fatigue cracking, SCC, or step wide cracking. It is a proven method for sizing indications and regular monitoring. Advanced PAUT flaw detectors like the M2M Gekko® or Mantis™ are used to also characterize HTHA cracking. Because HTHA defects are very small, it is quite difficult to detect them with conventional UT. By focusing the ultrasonic energy in a small spot, TFM is sensitive to these small defects. With TFM, an excellent resolution is obtained whatever the depth of the defects and 300-micron defects can be detected. This is why TFM has been integrated within the inspection scope by oil and gas companies around the globe as a means to detect HTHA damage at an early stage.

The Gekko is the ideal flaw detector offering at the same time conventional UT, standard PAUT, TOFD and real-time total focusing method (TFM). S-scans provided by the Gekko or Mantis differentiate between different stages of hydrogen induced cracking with concurrent scanning. To prevent critical plant equipment deficiencies, PAUT with TOFD can be employed to monitor blister cracks and stepwise cracking through a streamlined software interface, Capture™. The M2M Gekko has been successfully deployed for fastener-hole inspection in the aerospace sector as well as rolling contact fatigue (RCF) crack detection for the rail industry.

Eddyfi Technologies offers advanced non-destructive testing solutions for repeatable, actionable, meaningful and preventative data collection for the wide range of cracking inspection applications.