Keeping Pressure Vessels Safe with the Sharck Probe

Ask an expertPressure vessels are closed containers designed to hold fluids at pressures substantially different from the ambient pressure. These vessels are ubiquitous in refineries. Due to the critical nature of their function, pressure vessels must undergo regular and rigorous safety testing.

The Challenge

Develop an improved solution to replace wet MT on pressure vessel carbon steel welds.

Refinery pressure vessels are subjected to the harshest conditions around. Their carbon steel welds are critical components and they are prone to several cracking mechanisms in their different zones (toe, cap, heat-affected zone).

Pressure vessel welds in this application are often controlled with wet Magnetic particle Testing (MT), which uses particles suspended in a water or an oil solution. The particles can also be fluorescent to take advantage of the eye’s sensitivity to color.

Wet MT is, obviously, messy and requires surface preparation and post-inspection cleaning before being able to recoat the weld—time consuming. Other shortcomings wet MT are its inability to measure the depth of defects and its lack of archiving capabilities.

Any surface-breaking defects in pressure vessel carbon steel welds are target defects.

The Solution

The Sharck probe incorporating TECA™ technology to detect and size cracks.

This application required a solution that could address the shortcomings of wet MT, while, minimally, being as reliable.

Eddyfi Technologies' Sharck™ probe was designed specifically for this type of application. The probe’s spring-loaded fingers are designed to adapt to the geometry of weld crowns, which enables scanning cap, toe, and heat-affected zone in a single pass. The probe’s built-in encoder also makes it possible to precisely position defects along welds.

Contact us

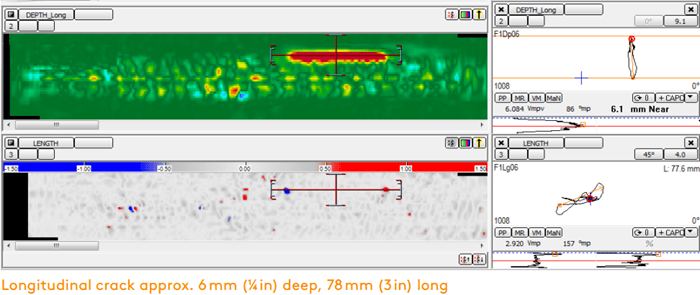

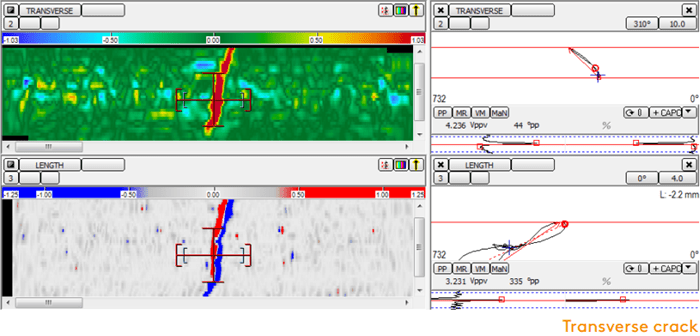

Unlike wet MT, the innovative Tangential ECA (TECA) technology incorporated into the Sharck probe can size the length and depth of cracks. It can do this without surface preparation of any kind, as it is designed to monitor liftoff (as opposed to cancelling it out) and compensate for it.

Sharck is also designed to scan at speeds up to 200 mm/s (8 in/s), fully record inspection data, and display it as intuitive 2D/3D C-scans thanks to the Ectane® testing instrument and Magnifi® software. Performing the inspection with Reddy® for surfaces (unavailable at the time) could have offered more portability and flexibility.

In the field, Sharck performed admirably, detecting and measuring cracking in the cap and toe of abrasive-blasted welds 12.7 mm (½ in) thick. The presence of cracks was confirmed with wet MT. Sharck was able to detect and size these, but also to detect transverse cracks, as demonstrated here.

Benefits

- Detecting and sizing the depth of previously undiscovered defects with little surface preparation and no chemical products.

The benefits of this probe are obvious:

Productivity gains

No need for surface preparation or postinspection cleaning.

Increased PoD

Detect previously undiscovered defects and size them.

Better reliability

Single-pass scanning with intuitive C-scan imaging.

Accountability

Full data archives to keep track of defect evolution.