The mining industry extensively uses oversized mechanical equipment, cast/forged components (such as gears and pinions in mills and kilns), crushers, cranes, hoist components, and heavy-duty vehicles specially designed for construction tasks - most frequently involving earthwork operations.

Details

Industrial equipment is subject to tremendous forces and taxed to the limit. Just like everything else, wear may cause mechanical failures… on a grand scale. The industry must implement thorough lifecycle management programs that involve preventative maintenance inspections (PMI) aimed at extending the fitness-for-service life of equipment. When it comes to the heavy industry and mining sector, human and environmental risks can only be effectively minimized through proactive, consistent maintenance and inspection of capital assets, infrastructure and working environments.

The industry typically employs highly user-dependent techniques to perform inspections. These include eddy current pencil probes, and methods that require thorough pre- and post-inspection cleaning. Eddyfi Technologies designs and markets test instruments and software that enables the industry to be less user-dependent. Our NDT solutions offer complete, computerized data recording and archiving capabilities. This gets you operational in a fraction of the time usually needed by other testing alternatives.

Typical Applications

- Surface-breaking cracks in large gears

- Macropitting in cast and forged components

- Generalized corrosion on complex systems

- Mine shafts, sumps and borehole condition evaluation

- In-service remote visual inspection(RVI)

- Mine hoists, or winder inspection including drum shaft, gearbox, and spindle assessment

- Monitoring erosion in long-radius piping bends, both buried and aboveground slurry lines, as well as corrosion tracking of assets within mining refineries and facilities using strategically installed sensors

For mining corporations, regular inspection of facilities and equipment is about maximizing up time, ensuring operational safety and minimizing revenue loss. Securing the right local partner for your NDT requirements is a key to success. Eddyfi Technologies has advanced solutions designed specifically for operations in heavy industry and mining applications.

In-line Applications

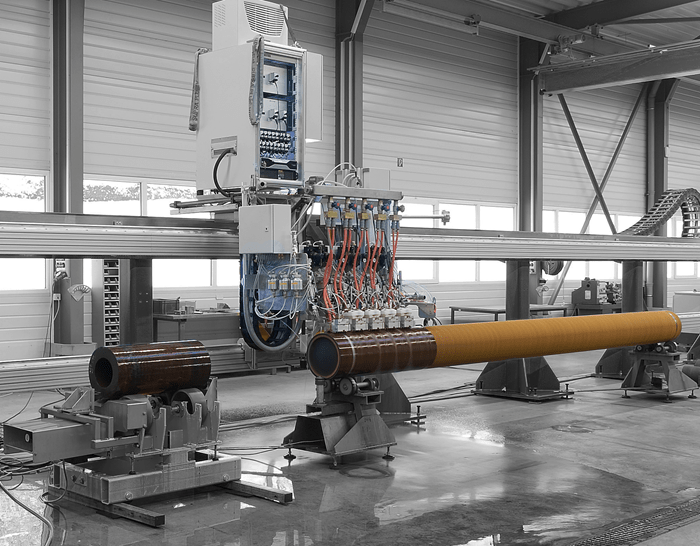

Heavy industry also means the manufacturing of industrial components. Phased array UT systems were developed to fulfill the needs of this manufacturing sector. These systems are meant for the production environment where productivity and reliability are key factors. Widely used by integrators to propose complete solutions to customers, these systems offer high speed and resolution inspection performance. Combined with an easy to use Software Development Kit (SDK), these solutions are above all the perfect candidates for any customer who wants to develop an integrated inspection solution.