Heat Exchanger Tubing Defects

Eddyfi Technologies for Heat Exchanger Tubing Defect Inspection Applications

Key assets in the power generation and chemical sectors, heat exchanger tubes require regular non-destructive testing (NDT) to detect flaws early, respond proactively and prevent critical failures or unplanned shutdowns. There are multiple factors that account for these flaws, and defects in heat exchangers cause weakened performance leading to increased operating costs. Thorough inspection of each heat exchanger section helps operators decide the next steps for repair and preventative maintenance.

Details

Given their objective of heating or cooling operations across industrial process plants, heat exchanger tubes are unsurprisingly prone to an assortment of potential defects. Key assets in the power generation and chemical sectors, heat exchanger tubes require regular non-destructive testing (NDT) to detect flaws early, respond proactively and prevent critical failures or unplanned shutdowns.

Common defects that inspection companies and asset owners investigate are:

- Internal and external corrosion

- Inlet end, steam, tube-to-tube or baffle plate erosion

- Fretting and wear including baffle (heat transfer) or saddle wear

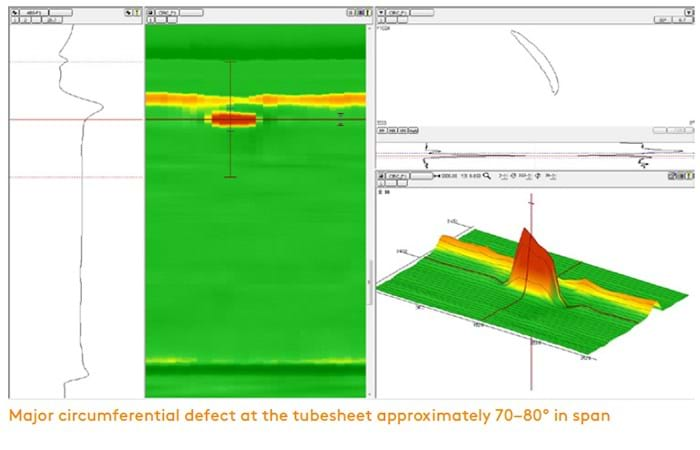

- Fatigue or creep cracks that are longitudinal, axial, or circumferential - especially at the tubesheet

- Carbon dioxide and oxygen pitting and dents

There are multiple factors that account for these flaws, and defects in heat exchangers cause weakened performance leading to increased operating costs. Thorough inspection of each heat exchanger section helps operators decide the next steps for repair and preventative maintenance.

Pitting, Corrosion and Erosion

Besides dents, tube wall pitting is often the by-product of a concentrated electrochemical gradient of oxygen and carbon dioxide. Bacteria is a factor for increased pitting in heat exchanger tubes, and insufficient cooling water treatment is a common cause of tube failure. Pits tend to form in cold fluids. Interestingly, hot fluids encourage uniform corrosion which is less problematic and indicative that high temperatures appear to slow the caustic process.

Corrosion and erosion impact both heat exchanger tube interior and exterior surfaces. Degradation may be caused by oxygen, chemicals, steam and water moving through the tubing. Chemical corrosion is the result of chemicals gradually wearing down the wall thickness of boiler tubes.

Cracking

Circumferential cracks and axial cracks in heat exchanger tubes commonly appear in:

- Steam generators

- At the tubesheet expansion transition area

- Bends

- On the top edge of the top support plate

- Condenser tubing

- At the tubesheet expansion transition zone

- Between support plates on the peripheral tubes

- Finned copper tubing in air conditioners

- From the root of the fin

- At the expansion transition zone

Fretting and Wear

Fretting in heat exchanger tubes is frequently the result of vibration causing them to rub with the baffle or saddle support and adjacent tubes. Fretting wear can potentially cause tube failure, which makes detecting these defects critical.

Dents

Dents in heat exchanger tubes may be the result of build up of corrosion between the tube and the baffle plate or tube support sheet, among other reasons. Heat exchanger tube dents can result in stress corrosion cracks (SCC) or fatigue cracking without any tube wall thinning.

No individual non-destructive testing (NDT) technique is adequate for all tubing applications, types of materials and defects.

Ferrous tubes are common in the shell-and-tube heat exchangers of the oil, gas, and petrochemical industry, among others, where inspection companies typically use RFT, NFT, NFA, MFL, and IRIS in various combinations to detect corrosion, pitting, cracking, and erosion in the tubes to maintain efficiency.

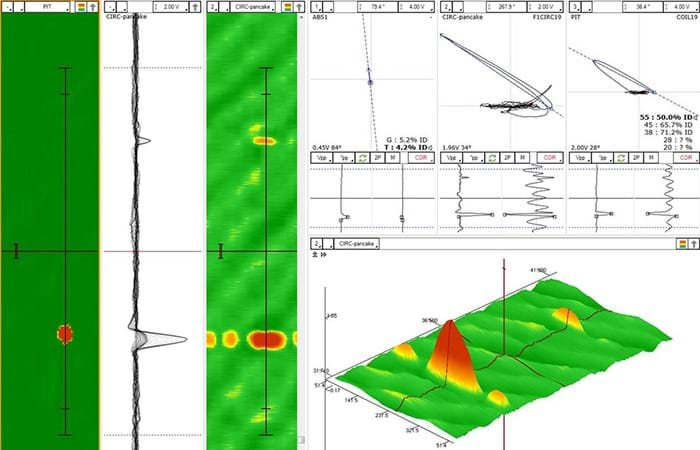

Non-ferrous metals (such as stainless steel, or Inconel) typically require Eddy current testing (ECT). The technique is used to detect corrosion and axial cracking (mostly) on the inner diameter (ID) and outer diameter (OD) of heat exchanger tubing surfaces. Flaws like corrosion pits and fretting grooves are easily detected when they are of significant size. Quantification of pitting, axial cracking, circumferential cracking and intergranular attack (IGA) requires specialized probes.

The Eddyfi DefHi® ECA probe is a multiplexed eddy current array (ECA) tubing probe capable of detecting, sizing and positioning circumferential cracks in the vicinity of the tubesheet of non-ferromagnetic heat exchanger tubes. It offers rapid assessment of circumferential cracks in the most challenging location with full 3D imaging for easier interpretation. The Eddyfi Ectane®, configurable for any type of inspection technique, Magnifi® acquisition and analysis software, and our patented Eddyfi DefHi ECA probe are a complete system for flaw detection and characterization, discriminating against unwanted signals like those from tubesheets and roll transition.

For air coolers, Eddyfi Technologies has taken near-field testing (NFT) to a new level, supercharging it with an array of coils, giving birth to near-field array (NFA) technology. It is designed to efficiently and reliably inspect aluminum-finned tubes and ferromagnetic heat exchangers. Aluminum-finned carbon steel tubes are the most challenging tubular component to inspect. The external aluminum fins on these tubes greatly influence the quality of inspection signals. Our NFA probes can easily detect common defects found in fin-fan air cooler tubes or ferromagnetic heat exchangers. They include inner diameter (ID) pitting, internal cracking at the tubesheets, internal erosion, and wall loss.

For chiller inspections, Eddyfi Technologies developed the Reddy® AC-E, a modern, portable system. Reddy AC-E is optimized to work with our range of AC probes which are designed with the best coil configuration, providing a low fin noise with a higher defect detection at straight sections, supports, tube expansions, and land areas. Moreover, in a single pull, the probe gives the inspector all the required data information for detection and defect characterization from the ECT bobbin and AC coil. The AC coil is required to detect circumferential cracking by subtracting the tube expansion effect, where cracks are mostly found.

Thermal performance of the heat exchange process is contingent on the NDT of assets found in high power generation units, crude oil distillation plants, chemical, and institutional sectors. Eddyfi Technologies offers advanced NDT solutions specifically designed for heat exchanger tubing defect inspection applications, enabling efficient asset management programs and peace of mind.