Pressure vessel owners are obligated to ensure their safe use. This requires effective inspection and maintenance programs. Owners are responsible for developing, documenting, implementing, executing, and assessing pressure vessel inspection systems and inspection procedures that meet relevant requirements.

Details

Pressure vessel owners are obligated to ensure their safe use. This requires effective inspection and maintenance programs. Owners are responsible for developing, documenting, implementing, executing, and assessing pressure vessel inspection systems and inspection procedures that meet relevant requirements. These systems and procedures typically include:

- Organization and reports of structure for inspection personnel

- Documentation and maintenance of inspection and quality assurance procedures

- Documentation and reports of inspection and test results

- Corrective actions for inspection and test results

- Internal audits for compliance with the quality assurance inspection manual

- Review and approval of drawings, design calculations, and specifications for repairs and alterations.

It is critical that remote visual inspection (RVI) and non-destructive testing (NDT) be performed to certify the compliance and fitness of service of these structures. Eddyfi Technologies’ adaptable and customer-centric solutions are used to detect structural flaws in process plant equipment, giving owners and operators the essential data they need for effective and efficient operations.

Vessel inspection includes inspecting vessel head nozzles, welds, expansion joints in transfer lines, and critical components or areas subject to corrosion. Visual inspection is universally accepted but often requires entering the vessel, taking the asset offline, and impacting productivity. Visual inspection is also used to determine the condition of the exterior insulation, allowance for expansion, and general alignment of a vessel on its supports. Any sign of leakage is investigated to identify its source.

Inspection for Corrosion Under Insulation (CUI) is considered for externally insulated vessels subject to moisture ingress. The need for internal visual inspection can be reduced or eliminated with advanced NDT methods including ultrasonic corrosion mapping for thickness measurement and flaw detection, Magnetic Flux Leakage (MFL), Tangential Eddy Current Array (TECA™), Pulsed Eddy Current (PEC), Alternating Current Field Measurement (ACFM®), and Remote Visual Inspection (RVI). Vessel integrity solutions depend greatly on the type of vessel, defect type, and regulations.

Ultrasonic thickness measurement inspection is used to determine the internal condition and remaining thickness of a vessel. Thickness measurements are collected in or out of service and by a qualified inspector. With advances in technology and reporting capabilities, more and more engineers recommend equipment which continuously records thicknesses as the scanning head moves over the inspection surface. Inspection results can be viewed in real time in the field or recalled for post-inspection analysis.

Corrosion Mapping

Ultrasonic corrosion mapping is generally the preferred method for inspecting critical vessels in the petrochemical sector. Ultrasonic corrosion mapping provides owners with detailed C-scan images of the surface under test using semi-automated scanning systems.

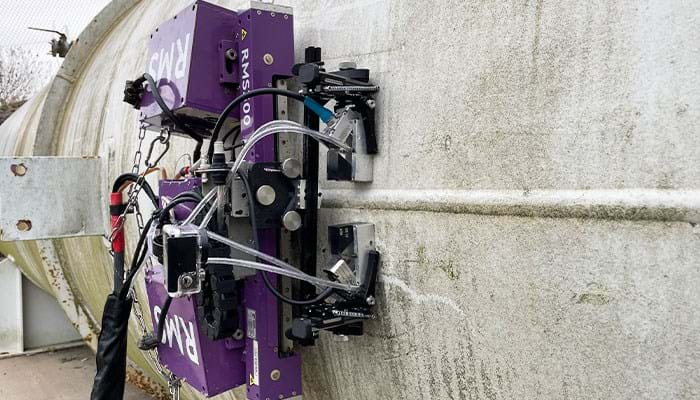

The RMS PA is a high-speed, remote access ultrasonic corrosion mapping system designed for circumferential scanning. To accompany the RMS PA is R-scan Array, designed for corrosion mapping of areas inaccessible to the semi-automated scanner, such as saddles and dome ends.

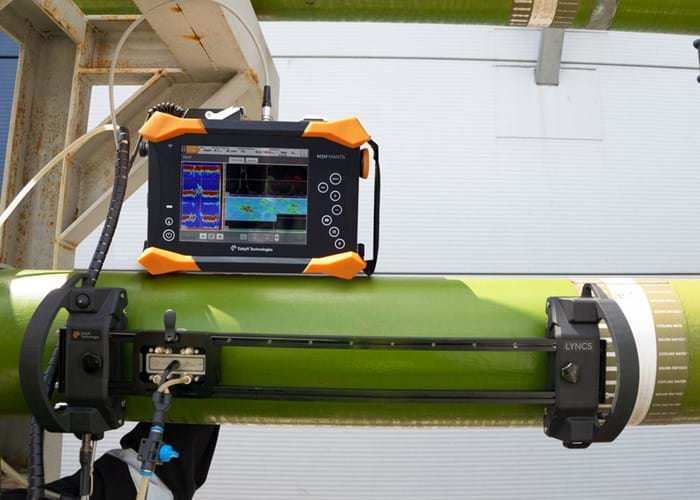

LYNCS CM manual scanner. Its extremely low profile and lightweight design is ideally suited to vessel and pipework in tight spaces, making it the most suitable option for rope access deployment and heavily congested pipework.

The R-scan Array is available as an independent manual scanner: simply connect it to an M2M instrument, (Gekko® or Mantis™), and you have a semi-automated phased array corrosion mapping system with onboard data collection capabilities.

Magnetic Flux Leakage is a corrosion screening technique unaffected by product in the vessel, so surveys can be carried out in or out of service. MFL is a quick and easy method used to detect corrosion, and then validated with ultrasonic testing (UT) for suspect areas.

The Pipescan HD is a cost-effective MFL inspection tool designed to operate not only on curved surfaces, but also on larger vessels, plates and tank shells.

Weld Inspection

Non-destructive testing (NDT) of welds has been an integral part of quality assurance programs for several decades. During the construction of vessels, welds have often been part of the primary focus to determine the overall integrity before entering service. This focus does not reduce during the asset lifespan, and the welds are often inspected during periodic integrity campaigns to ensure the overall fitness for in-service components.

Phased Array UT (PAUT) and Time of Flight Diffraction (TOFD) have become the go-to technology for both fabrication welding and in-service inspection. In addition, and in very recent times, Full Matrix Capture (FMC), Total Focusing Method (TFM), Plane Wave Imaging (PWI), and assisted defect analysis have taken advanced UT to another level.

LYNCS WI manual weld inspection scanner can accommodate up to 6 PA and/or TOFD probes and has a dual-bar structure for enhanced stability and probe placement accuracy. It is a toolless scanner with an interchangeable design, making it ideally suited to all weld inspection configurations.

Alternating Current Field Measurement (ACFM®) is a highly effective method for efficiently detecting and sizing cracks in a wide range of vessels and their connecting components. It is capable of performing these inspections through thick coatings and on both ferromagnetic and non-ferromagnetic materials, even at temperatures as high as 500°C (932°F). The Amigo2 ACFM instrument comes equipped with a comprehensive set of probes and accessories that are specifically designed for weld inspections in process plants. ACFM is covered in the ASME Boiler and Pressure Vessel Code (BPVC), Articles 15 and 31.

Tangential Eddy Current Array (TECA™) is an advanced electromagnetic inspection technology that uses ECA to introduce tangential currents into the surface of the vessel under testing to detect and size surface-breaking cracks. Developed to provide a solution to the shortcomings of Magnetic Particle Inspection (MPI), the Eddyfi Sharck™ probe incorporating TECA technology was designed to detect and size cracks in carbon steel welds. Prone to several cracking mechanisms in their different zones (toe, weld cap, heat-affected zone), refinery pressure vessels are subject to the harshest conditions demanding detailed structural integrity assessment. Unlike MPI, TECA technology and the Sharck probe can size the length and depth of cracks without surface preparation at high speed with single pass scans.

When it comes to insulated vessels, Eddyfi Lyft® is an advanced electromagnetic inspection tool leveraging Pulsed Eddy Current (PEC) technology used to locate and assess CUI. This innovative NDT tool is used to detect corrosion in ferrous materials typically hidden under layers of coating, fireproofing or insulation.

Inuktun robotic crawlers and inspection camera systems are designed to handle the high temperatures, potentially hazardous atmospheres, and other divergent circumstances that arise with pressure vessel inspections. The inherent dangers of manually inspecting pressure vessels found in the power generation industries are minimized with our remote inspection systems eliminating the need for human entry, which translates into the tremendous reduction of work-related health and safety risks, less downtime of the vessel and lowered costs during turnarounds. With crawlers like the Magg™, confined space entry is a concept of the past.

These periodic in- and out-of-service NDT assessments provide relevant data for primary pressure components right on time, every time, with Eddyfi Technologies’ advanced solutions for vessel inspection.