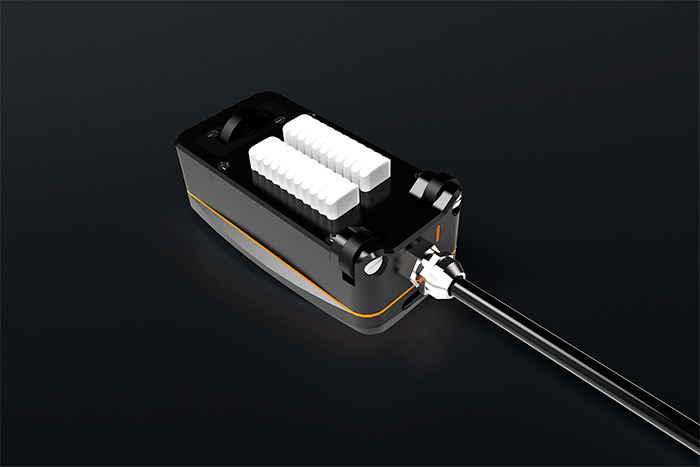

An evolution making it even easier and faster to detect and size cracks in carbon steel.

Features

- Ceramic tip

- Ergonomic design

- ASTM E3052 compliant

Details

The innovative design of the patented Sharck™ probes is capable of addressing the inspection needs of several industries relying heavily on carbon steel, such as the onshore and offshore oil and gas, wind power, and structural industries.

Sharck is specifically designed for cracking in carbon steel using Tangential Eddy Current Array (TECA™) technology. These probes are capable of positioning cracks, measuring their length, and sizing them as deep as 7 mm (0.28 in). This can be achieved without removing paint or protective coatings, unlike more conventional techniques.

How Does it Work?

Traditional pancake coil axes are perpendicular to the surface under test. TECA, on the other hand, uses tangential coils positioned on their sides, their central axes parallel to the surface under test. Eddy currents also flow parallel to the surface making them capable of “diving” under cracks. Find out more on the TECA page.

Probes Features

Butt and Fillet Weld Probes

- Embedded control buttons

- Removable parts for easy cleaning and maintenance

- Independent, spring-loaded fingers adapting to weld geometries

- Built-in, high-resolution encoder

Pencil Probes

- Straight and right-angle configurations

- Slim design for restricted access scans

- Convenient attachment ring

High-resolution Probe

- Semi-flexible design compatible pipe diameters ranging from 254–1220 mm (10–48 in)

- Single-pass detection and depth measurement of short, shallow cracks such as SCC clusters

- Fast—Up to 600 mm/s (24 in/s)

Benefits

Advanced Array Technology

- Incorporates tangential eddy current array (TECA)

- Fast — Up to 600 mm/s (2 ft/s) depending on the probe model

- Single-pass detection of longitudinal and transverse cracks

- Wide coverage

- High-performance multiplexing for optimal sensitivity

- Reliable, less operator dependent compared to alternatives

Advanced Software

- Easy interpretation with intuitive encoded 2D/3D C-scans

- Actual crack depth measurements — Not based on theoretical modelling

- Automatic readings — Crack length and depth, liftoff

- Auto-compensation — Live monitoring of liftoff and permeability variations

- Full data recording and archiving capabilities

In Line With Recognized Eddy Current Certifications and Standards

- Sharck probes return signals similar to conventional eddy current testing signals, making the technology easy to learn. The probes also comply with ASTM E3052

Specifications

BUTT WELD PROBE

- 53 mm (2.1 in)

- 22 (11 × 2 rows)

- 64

- 25.4 cm (10 in)

- 40.6 cm (16 in)

FILLET WELD PROBE

- 30 mm (1.2 in)

- 12.4–23.0 mm (0.50–0.91 in)

- 12 (6 on cap, 6 on HAZ)

- 32

- 31.8 cm (15 in) concave and convex

PENCIL PROBE

- Approximately 7 mm (0.3 in) at –6 dB

- 1

- 32

PERFORMANCE

- Length: 3 mm (0.12 in)

- Depth: 0.5 mm (0.02 in)

- Results may vary according to crack location, liftoff, etc.

- 7 mm (0.28 in)

- Typical, with good accuracy, but can detect deeper cracks

- ±2 mm (0.08 in)

- Typical when using 0.5 mm (0.02 in) scan resolution

- ±10–20%

- Depending on the condition of the weld

- Up to 200 mm/s (7.9 in/s)

- With full data recording

- Up to 3 mm (0.12 in)

- Non-conductive coatings and paints, with monitoring and auto-correction

Wide variety of carbon steels. Tested on:

- AISI 1018, 1020, 1045, 1117, 4140

- SA516, 537, 387

- API 2W60

- ABS A131

- More

HIGH-RESOLUTION PROBE

- 71 mm (2.8 in)

- 64

- 254–1220 mm (10–48 in)

PERFORMANCE

- Length: 2 mm (0.08 in)

- Depth: 0.25 mm (0.01 in)

- Results may vary according to crack location, liftoff, etc.

- 3 mm (0.12 in)

- Typical, with good accuracy, but can detect deeper cracks

- ±10%

- Presence of corrosion may impact accuracy

- Up to 600 mm/s (24 in/s)

- With full data recording

- Up to 2 mm (0.08 in)

- Non-conductive coatings and paints, with monitoring and auto-correction

- X52 grade steel

- X56, X60, and more grades to be supported