Magnetic Flux Leakage (MFL)

Magnetic flux leakage (MFL) is an electromagnetic non-destructive testing technique used to detect corrosion and pitting.

Details

How it Works

MFL uses a powerful magnet to magnetize the conductive material under test (usually steel). Where there are defects — corrosion or material loss — the magnetic field “leaks” from the steel.

MFL probes incorporate a magnetic detector placed between the poles of the magnet where it can detect the leakage field. During inspection, a magnetic circuit of sorts forms between the part and the probe. The magnetic field induced in the part saturates it until it can no longer hold any more flux. The flux overflows and leaks out of the pipe wall and strategically placed sensors can accurately measure the three-dimensional vector of the leakage field.

Because magnetic flux leakage is a vector and that a sensor can only measure one direction, any given probe must have three sensors to accurately measure the axial, radial, and circumferential components of an MFL signal.

Ask an ExpertBenefits

Using MFL can yield the following benefits:

- One of the few methods used to inspect finned tubes ( NFT is also an alternative)

- Can be used on all ferromagnetic materials

- Good sensitivity to pitting

- High-speed inspection

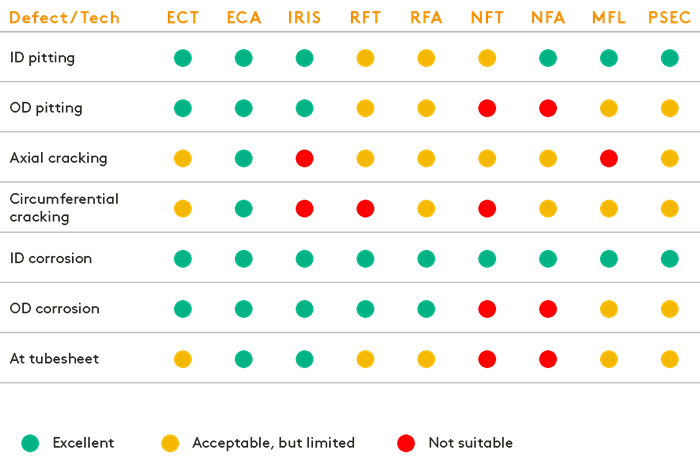

Detection Capabilities According to Defect Type in Tubing

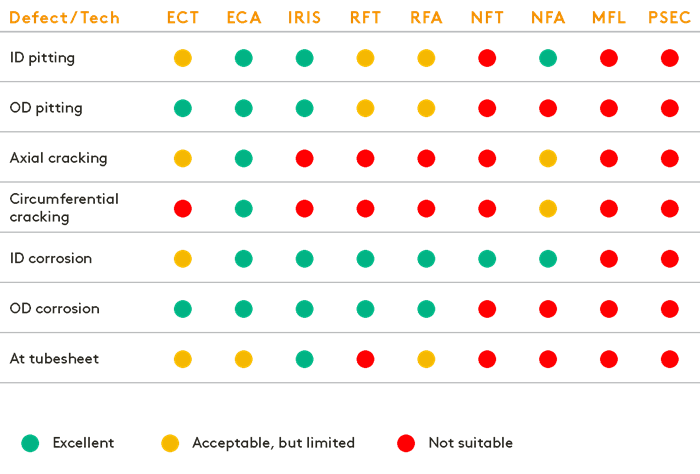

Sizing Capabilities According to Defect Type in Tubing

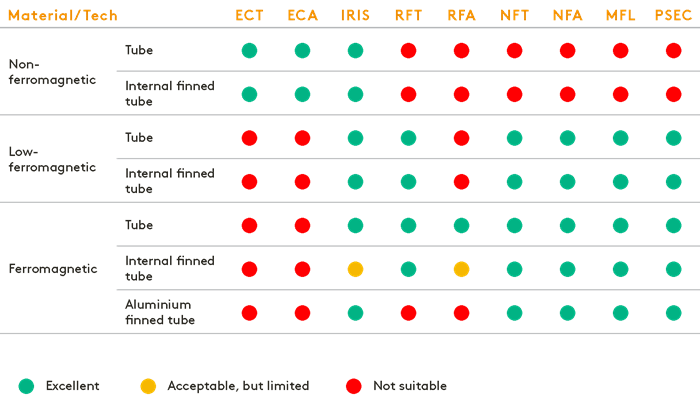

Suitability According to Tubing Material

Learn more