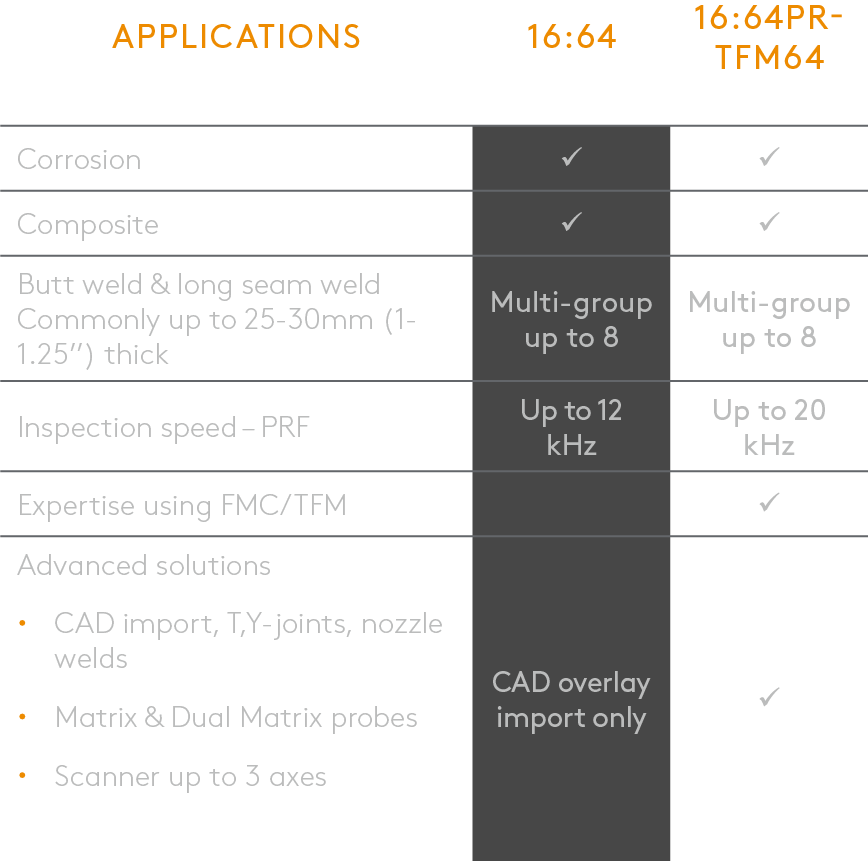

MantisTM is a robust and lightweight flaw detector offering ultrasonic testing (UT), phased array UT (PAUT), time-of-flight diffraction (TOFD), and total focusing method (TFM) through the streamlined user interface called CaptureTM. Based on a 16:64PR architecture with two different models, Mantis addresses both general and advanced applications without compromising productivity.

Details

Made for the Field

Discover our application solution kits here

- Portable, reinforced robust casing designed for IP65

- Compact and light for easy operation

- Resistive touch screen technology (glove compatible, not dust/water sensitive)

- High storage capacity – 128GB SSD

- IPEX PA, LEMO-00 UT and LEMO-16 encoder connectors

- Embedded easy latch adaptor available

- One internal battery + one hot-swappable battery

- Connectivity with WI-FI, USB 3, and Gbit Ethernet

Upgrade options are available for the Mantis-16:64. Contact us for expert advice.

Designed for Your Inspection

- 16:64PR architecture plus two UT channels verified with international standards

- Compatible with existing phased array probes (linear, dual linear, and dual matrix array) and existing scanners (up to three encoder axes)

- Embedded focal law calculation (sectorial, linear, compound)

- Up to eight group configurations

- High inspection speeds thanks to PRF up to 20 kHz

- Real-time full matrix capture (FMC)/TFM with up to 64 elements for code compliant inspections

PAUT and TOFD Weld Inspection

Mantis performs weld inspections on components with simple and complex geometry, including curved surfaces, flat plate, pipelines, and restricted access areas. The ability to import custom CAD overlays simplifies analysis and can reduce false calls.

Whatever your inspection procedure, PAUT, ToFD, and TFM are available to support your Probability of Detection (PoD) needs.

Ready to discover how Mantis could work for you? Let us know!

Streamlined Experience, Built into Mantis

Mantis includes a powerful embedded software platform that simplifies every stage of the inspection workflow, from calibration to analysis to final reporting. Designed for ease of use in the field, it provides inspectors with a consistent, productive, and code-compliant experience.

The guided wizards make calibration fast and accurate, covering velocity, wedge delay, angle calibration, amplitude balancing, and time-corrected gain (TCG).

Mantis supports real-time TFM with multi-group and multi-mode configurations, including Phase Coherence Imaging (PCI) and Pitch & Catch techniques.

Embedded scan planning tools allow you to import CAD files, calculate focal laws, and adapt to complex geometries with ease.

Assisted defect analysis features include auto-sizing, customizable indication tables, and data stitching.

All of this is supported by remote access via Wi-Fi, USB 3.0, and Gigabit Ethernet, with the option to transfer files to PC for offline setup and detailed reporting.

Protect Your Investment. Maximize Uptime. Unlock More Value.

To help you succeed throughout the lifecycle of your equipment, Eddyfi Technologies offers the Customer Success Program (CSP), designed to reduce downtime, boost productivity, and protect your investment.

With varying levels of access tailored to your unique needs, the CSP provides a flexible suite of services including:

- Annual calibrations

- Accidental damage protection

- On-demand eLearning

- Collaborative support tools

- And more!

Whether you're looking for peace of mind, compliance support, or enhanced efficiency, the CSP strengthens our partnership and ensures you get the most from your Eddyfi solution.

Exclusive Content

Workshop Capture 3.2 for welds

Pause-café avec Eddyfi | Inspection de soudures à l’aide d’une configuration multigroupes TFM

Coffee Break presented in French

Performance des outils d’analyse Capture pour l'inspection de soudures (PAUT, TOFD et TFM)

Workshop presented in French.

Ultrasons multi-éléments et TFM : puissance combinée pour l'inspection de structures critiques

Workshop presented in French.

Life is better with TFM: How can the game-changing method enhance your inspections in real-time

In this Webinar, you’ll learn:

- How Eddyfi Technologies, as TFM pioneers, implemented new options for real-time TFM in its instruments (such as plane wave imaging),

- How this innovative NDT technique can enhance your NDT inspections

- How codes and standards are accounted for directly in the system to guarantee the compliance of all setup parameters

- How intuitive and easy it is to use TFM within the Capture software, especially with 3D and toolbox analysis.

The webinar includes a presentation of the technique, illustrates the power of the Capture interface, features a demo portion and addresses some of the most frequently asked questions.

How to simplify welds NDT inspection using Total Focusing Method (TFM) and Phased Array UT (PAUT)

Girth-weld inspections require numerous parameters to be specified on most flaw detectors. The Mantis user interface solves these challenges. Using off-the-shelf probes, the NDT inspector can quickly configure his unit, scan, and analyze the collected data with confidence.

In this Webinar, you’ll learn:

- How fast Capture makes it easy to get ready to scan using ultrasonic techniques such as Total Focusing Methods (TFM) and Phased Array (PAUT), how streamlined is the analysis of TFM data and how chosen approaches compare

- How adding TFM to a PAUT unit overcome limitations of each technique

- A case study: girth-weld inspection setup, data acquisition, and analysis overview

Weld Inspection Paparazzi | World Pipelines Article

This exclusive content discusses the use of ultrasound imaging techniques for inspecting pipe welds of varying conditions.

Specifications

Instrument

311 × 220 × 95mm (12.2 × 8.6 × 3.7in)

4.2kg (9.5lb)

4h (hot-swappable battery)

8.4in high contrast resistive screen

1024 × 768px

128GB SSD

IP65

-10°C - 45°C (14°F - 113°F)

-10°C - 60°C (14°F - 140°F)

According to MIL-STD-810G 1

Download

- Mantis Technical Specifications

- Capture Technical Specifications

- Cleaning tips and tricks

- Non-Intrusive Inspection Applications Brochure

- Train Axle Inspection Applications Brochure

- Wet Hydrogen Sulfide Damage Applications Brochure

- High Temperature Hydrogen Attack (HTHA) Applications Brochure

- Corrosion Mapping Applications Brochure

- Advanced Weld Inspection for Carbon Steel Applications Brochure

- Advanced Weld Inspection for Boiler Tubes Applications Brochure

- Advanced Weld Inspection for Austenitic Steel Applications Brochure