Eddyfi Technologies' semi-automated inspection solutions combine advanced precision and ease of use to streamline NDT applications. These scanners deliver high-quality data for both corrosion mapping and weld inspection tasks, offering versatility across a range of industries. With efficient deployment, our solutions reduce manual intervention while enhancing productivity and data accuracy. Ideal for challenging environments, these systems help ensure reliable, consistent results, improving asset integrity management and inspection workflows.

Details

Our semi-automated UT scanner solutions are engineered for precision, productivity, and adaptability in applications such as:

- Corrosion Mapping View Brochure

- High Temperature Hydrogen Attack Detection View Brochure

- Boiler Tube and Small Diameter Pipe Weld Inspection View Brochure

- Austenitic Stainless Steel Weld Inspection View Brochure

- Carbon Steel Plate and Pipe Weld Inspection View Brochure

- Wet Hydrogen Sulfide Damage Assessment View Brochure

- Train Axle Inspection View Brochure

Semi-Automated Corrosion and Weld Inspection

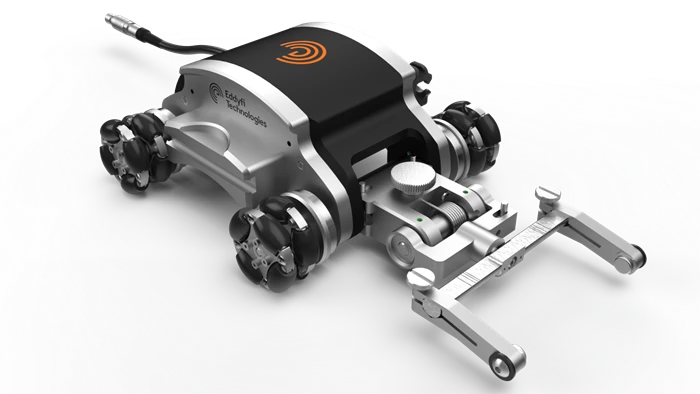

The handheld NDT Sweeper is a highly versatile and easy-to-deploy semi-automated 2D encoded scanner which can virtually replace multiple specialized scanners due to its ability to perform corrosion mapping and weld inspections. The scanner is the perfect solution for the inspection of complex geometry components including curved surfaces, flat plate, pipelines, and restricted access areas.

Thanks to its small, lightweight, and ergonomic design, NDT Sweeper can easily scan in many difficult-to-reach areas eliminating the need to deploy an automatic scanner in those situations. The system encodes in both axis so there is no need to draw an index line on the specimen when scanning.

Learn more

Semi-Automated Corrosion Inspection

The PaintBrush2 has set a new market benchmark for corrosion mapping. This extremely agile and patent-protected scanner performs both flat and curved surface inspections, increasing inspection confidence by providing 100% area coverage.

The product's intuitive operation makes corrosion mapping quick and straightforward. Coupled with the Cypher® ultrasonic instrument — featuring a wealth of corrosion specific features.

Designed to meet a wide range of demanding inspection requirements, the PaintBrush2 pushes boundaries. With an extensive operating temperature range, broad probe compatibility, and the freedom to collect data without grid constraints, it adapts to diverse inspection scenarios with precision and flexibility.

Learn more

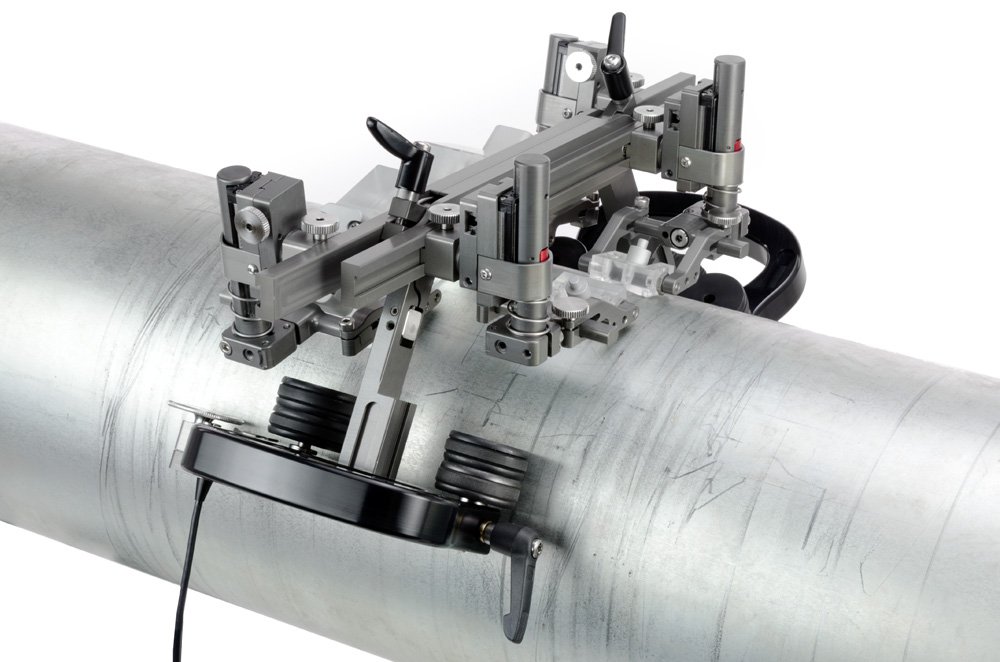

Semi-Automated Carbon Steel Weld Inspection

This highly adaptable weld inspection system for ferrous materials supports up to four Phased Array (PA) and/or Time of Flight Diffraction (TOFD) probes. Designed with versatile, precision-adjustable toolposts, the scanner ensures exceptional probe placement accuracy across multiple configurations. Its adjustable spring load minimizes setup adjustments, making it ideal for any weld inspection requirement.

Learn more

For longitudinal weld inspections, the innovative long seam system efficiently handles both long and circumferential welds, providing the perfect solution for seam weld inspection, including applications like excavations and Electric Resistance Welded (ERW) seams.

Learn more

Semi-Automated Non-Ferrous Weld Inspection

When faced with the challenge of inspecting non-ferrous materials, the advanced chain scanner ensures exceptional alignment, stability, and precise encoded probe positioning. This versatile scanner accommodates a wide range of materials, including austenitic steel, glass fiber-reinforced plastic (GFRP/GRP), carbon fiber-reinforced plastic (CFRP/CRP), high-density polyethylene (HDPE), and various plastics. Multiple configurations are available to suit diverse inspection requirements.

Learn more

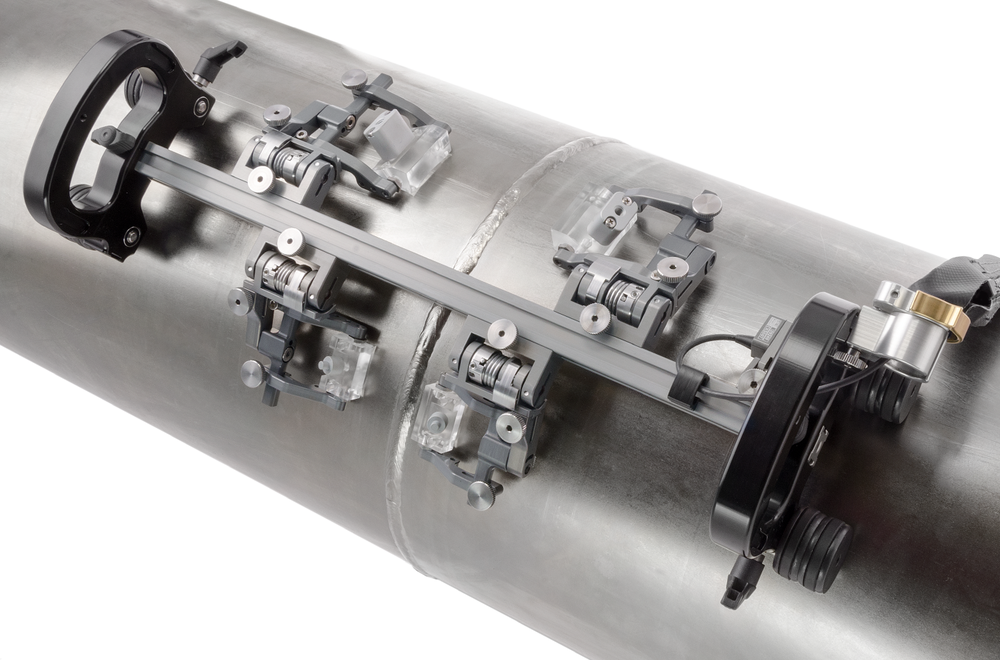

Semi-Automated Bore Tube – Small Bore Weld Inspection

The ultra-low-profile, single- and dual-sided scanner solution provides high-quality inspection results, essential for ensuring weld integrity and maintaining the safety and reliability of components throughout their lifespan. While radiography was once the primary inspection method, Phased Array Ultrasonic Testing (PAUT) has become the preferred approach for its accuracy and efficiency. This scanner enables rapid, precise encoded probe positioning for circumferential inspections of small-diameter pipes and tubes.

Learn more

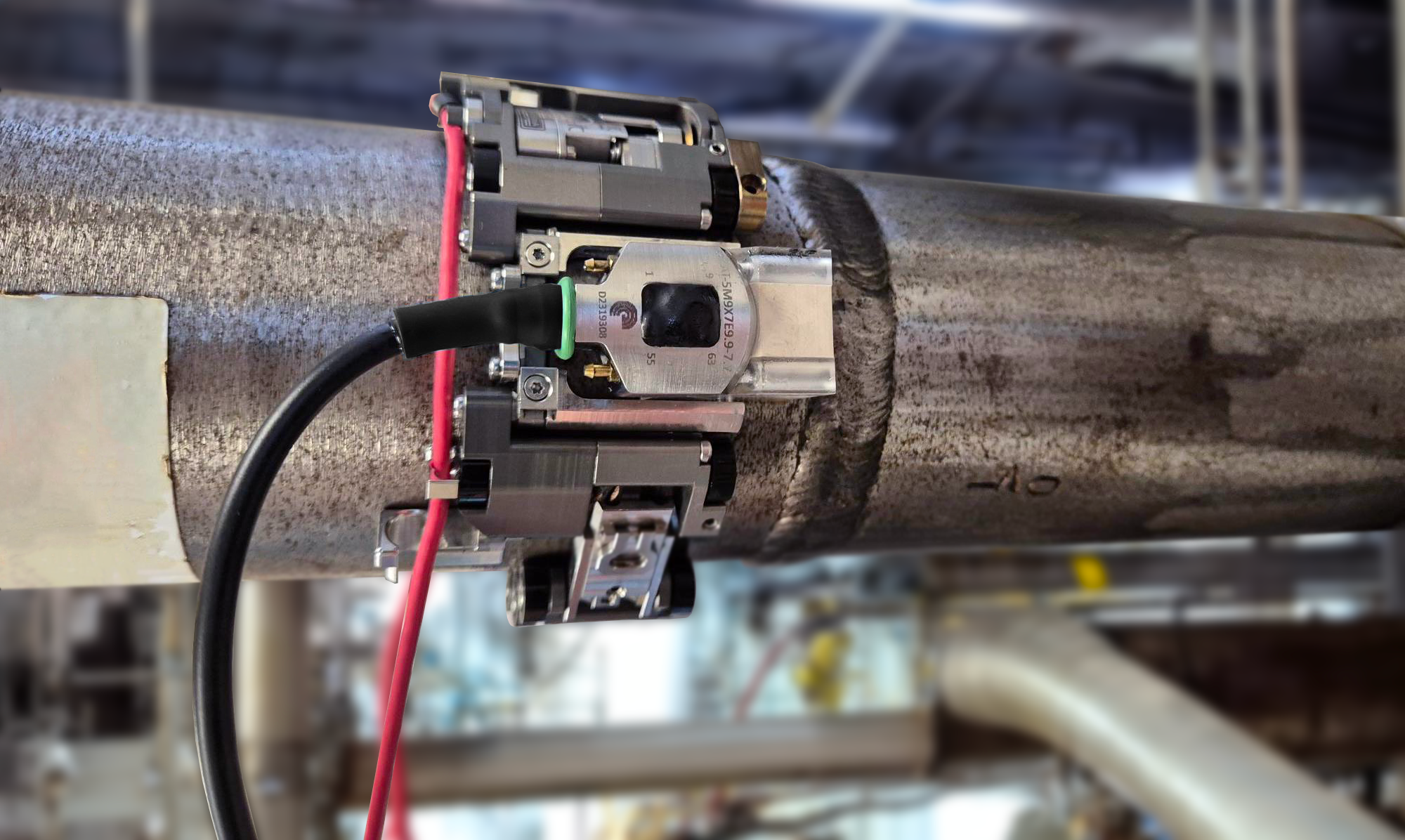

Semi-Automated High Temperature Weld Inspection

Reduce operational risk and boost productivity with on-stream asset intelligence, even at continuous use temperatures up to 350°C (662°F). Conduct weld inspections on hot, active assets without the need for shutdowns or isolation.

Learn more

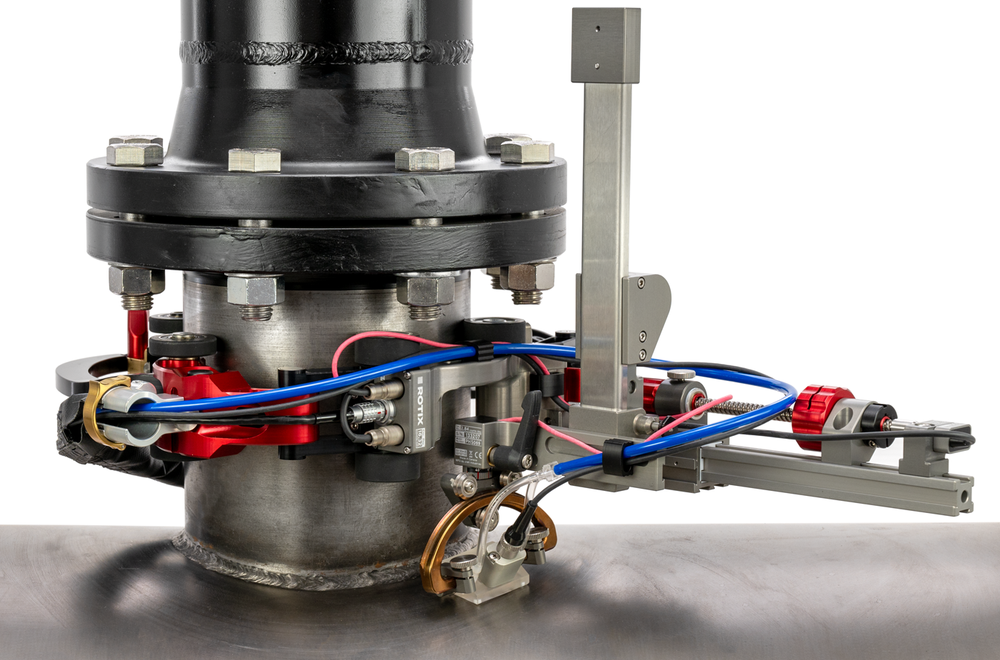

Semi-Automated Nozzle Inspection

A versatile manual scanning solution designed specifically for inspecting nozzle welds, compatible with both two-axis and three-axis instruments. Adaptable to a broad range of 90-degree nozzle sizes starting from 76.2mm (3in) and suitable for ferritic and austenitic materials. The nozzle scanner offers native compatibility with the Gekko system and requires only 127mm (5in) of clearance.

Learn more

String Encoder for Entry Level Inspection

Wire encoder incremental. Standard linearity of +/-0.20%. Index of protection: IP50. Includes magnets for ease of use.

Contact us