Eddyfi® has taken Near-Field Testing (NFT) to a new level, supercharging it with an array of coils, giving birth to the Near-Field Array (NFA) technology. It is designed to efficiently and reliably inspect aluminum-finned tubes and ferromagnetic heat exchangers.

Features

- High-resolution array fin-fan air cooler tube inspection at NFT speeds

- Axial and circumferential crack detection in a single pass

- Intuitive C-scan imaging

- As easy to use as NFT probes

- Hardened-steel, replaceable wear guides

- Rugged design and kink-resistant poly

- Wide variety of probe diameters

Details

Aluminum-finned carbon steel tubes are the most challenging tubular component to inspect. The external aluminum fins on these tubes greatly influence the quality of inspection signals. Our NFA probes can easily detect common defects found in fin-fan air cooler tubes or ferromagnetic heat exchangers. They include: Inner Diameter (ID) pitting, internal cracking at the tubesheets, internal erosion, and wall loss.

Webinar

Fin-Fan Air-Cooled Heat Exchangers: Inspection Technique Comparison for Optimal Results

Need help finding the right tubing probe?

Benefits

Array Performance and Quality

Eddyfi NFA probes can have up to 30 coils, optimized for performance. They are multiplexed, which yields high-quality signals, enables C-scan imaging at a scan speed of 305 mm/s (12 in/s) in tubes ranging from 19.05 to 38.10 mm (0.75–1.5 in).

Detection Capability

NFA gives our probes the high-resolution necessary to reliably detect small volumetric defects (approx. 3 mm/0.125 in) in a single pass.

Ease of Use

Unlike other inspection techniques, our NFA probes are easy to use. Because they don’t incorporate any magnets, they are easy to push and pull through tubes, and are not as sensitive to pull speed as MFL probes. NFA probes also do not require water or complex tools, making them much easier to use than IRIS.

Intuitive Imaging

With Eddyfi’s Magnifi®, you can display NFA probe data as 2D/3D C-scans, which are intuitive and rich in information. This enables the discrimination and sizing of defects.

Durability

Our NFA probes are equipped with hardened-steel, wear-resistant guides to maintain a constant liftoff and yield more reliable results. These guides are replaceable, so when they do wear down, it’s easy to keep using the same probe.

They are also equipped with a high-end, kink-resistant poly, enhancing probe usability and life.

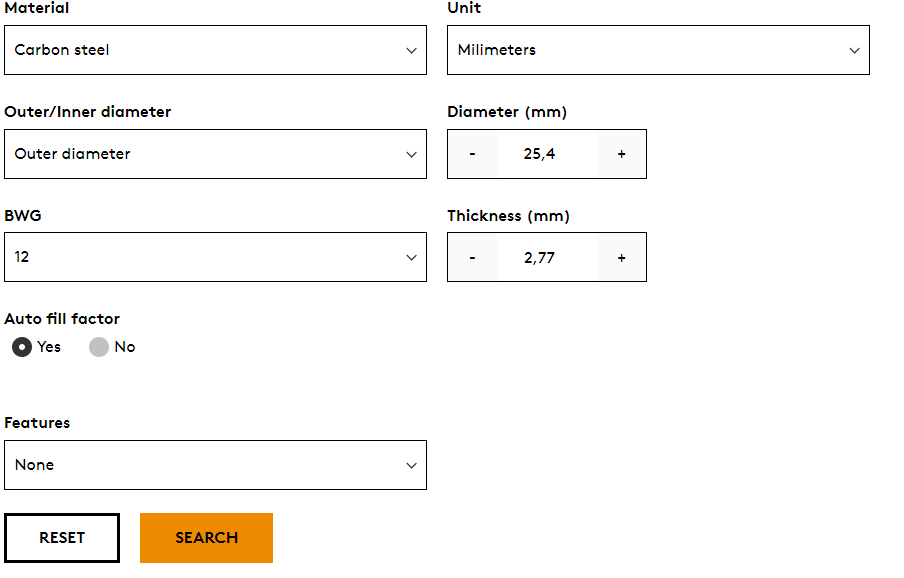

Use the part number finder to see what Eddyfi probes are available or use the tubing probe creator to determine what probes are best for your particular application.

Specifications

GENERAL

- Absolute

- Array (pitting, circumferential, and axial)

- 305 mm/s (12 in/s)

- 3 mm (0.125 in)

- Ferrous, carbon steel and low-carbon steel alloys

- 9 mm (0.375 in) premium, non-kink nylon

- 160-pin array connector

- Modified NFT calibration standard