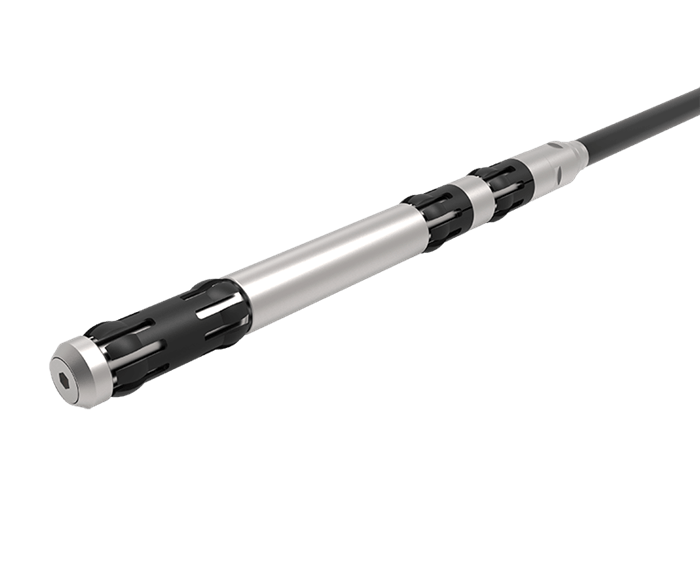

The DefHi® probe is Eddyfi® groundbreaking high-definition, multiplexed Eddy Current Array (ECA) probe. It’s designed to inspect the non-ferromagnetic tubing in condensers, feedwater heaters, and heat exchangers.

Features

- One-pass combination bobbin and array probe

- Sizing of circumferential and axial cracks*

- Optimum resolution and uniform sensitivity with oval-coil technology

- Uncompromising durability (highly kink-resistant cable, replaceable centering devices)

- Wider frequency range (HW to HF)

- Convenient analysis with strip chart for bobbin and 2D/3D C-scans for array imaging

*Available with advanced options only

Details

It can efficiently detect circumferential cracks at tube support plates and tubesheets—something conventional bobbin probes notoriously fail at. The DefHi can also detect and size typical defects in any orientation such as wear, corrosion, and micropitting, as well as detect Stress Corrosion Cracking (SCC). The probe’s unique ECA multichannel design offers the same performance as a rotating probe, but at bobbin probe speeds, all in a single pass.

*Patented

Need help finding the right tubing probe?

Benefits

Better Sensitivity

The DefHi probe provides superior sensitivity through its high-definition, multiplexed ECA design. Utilizing electronic channel multiplexing, it leverages time slots across up to 128 Eddy Current Testing (ECT) channels, enabling consistent, uniform high-definition sensitivity. This advanced configuration allows DefHi to detect and identify defects in any orientation, addressing a significant limitation of conventional bobbin probes. Unlike non-multiplexed array probes and A/C probes, which are constrained by the limited number of physical channels in typical ECT testers (usually 4 or 8), DefHi’s setup ensures precise detection, offering exceptional clarity in defect identification.

Better Speed

The DefHi probe excels in speed, combining the rapid acquisition rates of bobbin probes with the expanded channel capabilities that support complete tube inspections. Unlike rotating (RPC) probes, which are slower, the multichannel configuration of DefHi allows for fast scanning across entire tube lengths. This capability enables comprehensive and efficient inspection, making it a high-speed solution for thorough tube evaluations without sacrificing accuracy.

Better Visualization

With DefHi’s advanced multiplexed ECA technology, users gain enhanced visualization of inspection data. Its design allows the probe to overcome the limitations of conventional tube inspection techniques, providing high-resolution imaging and insight into the circumferential extension of defects — a major improvement over bobbin probes. Available in various configurations and sizes, DefHi delivers precise, reliable visual data, facilitating clearer identification and sizing of defects across diverse inspection scenarios.

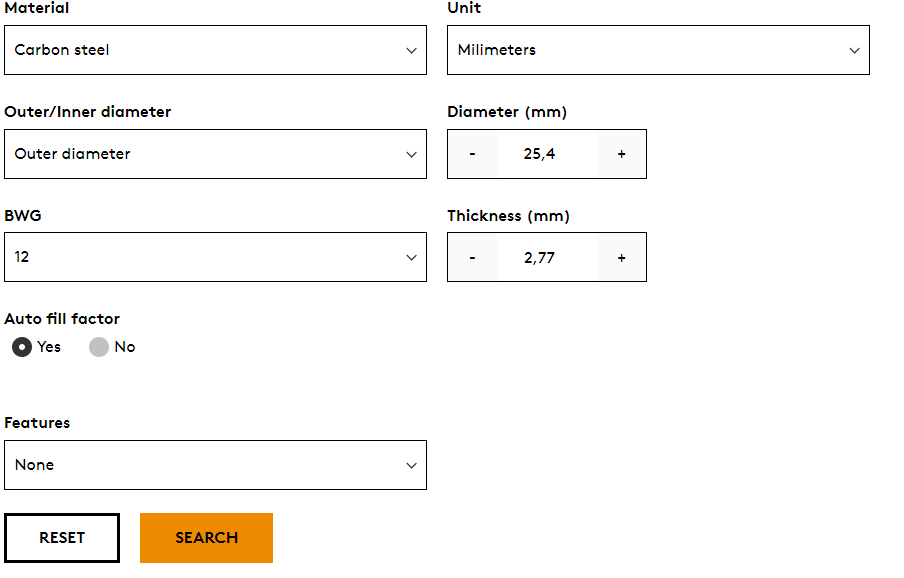

Specifications

GENERAL

- Differential and absolute bobbin

- Transmit-receive array oval pancake coils

- 1 × row for circumferential defects

- 2 × rows for circumferential and axial defects

- 1 m/s (39.4 in/s)

- 9 mm (0.375 in)

- Non-kink nylon

- Modified ASME standard

- 160 pins