Details

ACFM Subsea Inspection System for the Detection and Sizing of Surface-breaking Cracks

For the last 30 years, ACFM® technology has been used globally as the method of choice for the detection and sizing of subsea surface-breaking cracks. Recognized and approved by many certification bodies, including DNV, ABS and Lloyds, the technique has been used successfully against traditional uncomputerized and more user dependent methods, such as MPI.

As today’s industry is looking to scale the use of auditable NDT methods to all their assets, faster, more flexible, easier to deploy inspections and better reporting capabilities are required. Who else but Eddyfi Technologies to redefine and modernize subsea crack inspection with its new U41™.

The U41 is supported by a global network of calibration and training centres, located in Milton Keynes (UK), Québec (Canada), Houston (USA) and Dubai (UAE).

Want to see U41 in action? Book a demo!

Deployment Method

Diver from fixed platform, vessel or from saturation bell (U41D / U41DA)

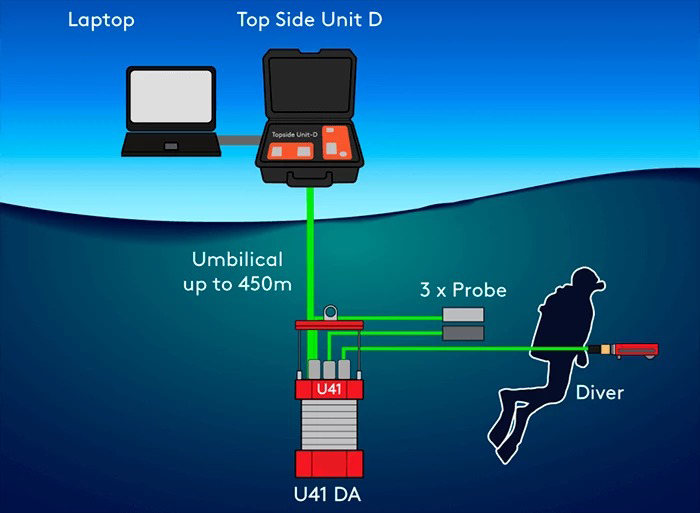

The subsea bottle is lowered to the diver and the diver uses probes connected to the bottle through a 5 m (16.4 ft) cable. There is an umbilical cable from the bottle to a topside unit that provides power to the bottle and communication protocol conversion between the VDSL used down to the bottle and Ethernet which is connected to a controlling laptop. The umbilical is 150 m (492 ft) standard with subsea connectors at both ends. Three umbilicals may be connected together for a total length of 450 m (1476.4 ft). A 15 m (49.2 ft) whip is provided between the top umbilical and the topside unit so that this can be temporarily fixed-routed to the dive shack (normal ACFM operator location). The diver uses simple Bx/Bz pair probes or the mini (8 channel) array (requires the DA version).

A New Platform for Evolution

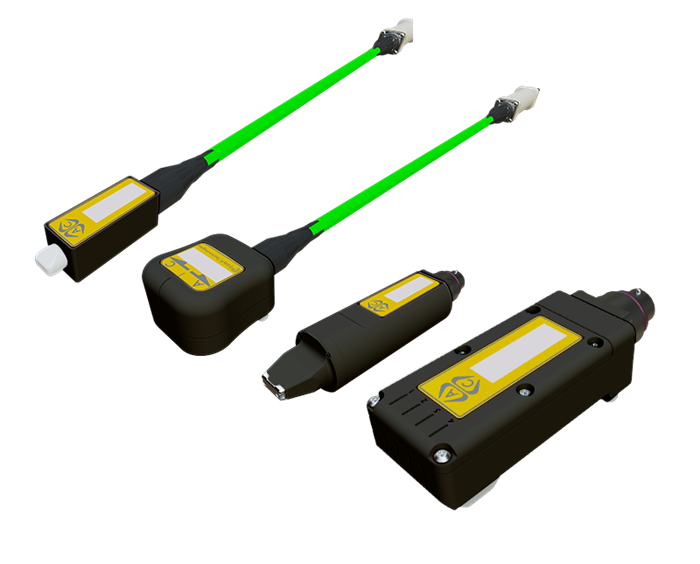

U41 features a SENSU® 2 connectors which will be used by a new generation of ACFM probes—manual or array. The SENSU 2 connector supports up to eight digital inputs for high-speed, large-array applications.

- Faster than the previous legacy probes – 2 outputs

- Rated IP68 down to 300m underwater

- All probe data stored in probe’s memory.

- Familiar probe bodies with updated electronics, cables and connectors

Together, U41 and its Assist software are fully designed and ready to support the evolution of ACFM probes.

Available Probes

Download Assist Software

Protect Your Investment. Maximize Uptime. Unlock More Value.

To help you succeed throughout the lifecycle of your equipment, Eddyfi Technologies offers the Customer Success Program (CSP), designed to reduce downtime, boost productivity, and protect your investment.

With varying levels of access tailored to your unique needs, the CSP provides a flexible suite of services including:

- Annual calibrations

- Accidental damage protection

- On-demand eLearning

- Collaborative support tools

- And more!

Whether you're looking for peace of mind, compliance support, or enhanced efficiency, the CSP strengthens our partnership and ensures you get the most from your Eddyfi solution.

Exclusive Content

Modernizing subsea ACFM inspection with U41

The webinar features a demonstration where Dr. Michael Smith shows you how the U41 true ACFM subsea inspection system delivers accurate subsea crack detection and sizing, better data quality with new electronics, faster inspection with easier deployment, array probed and reporting.

The webinar will include:

- An introduction to the U41

- An overview of the main features and applications

- A demonstration of system

- Q&A

Specifications

GENERAL

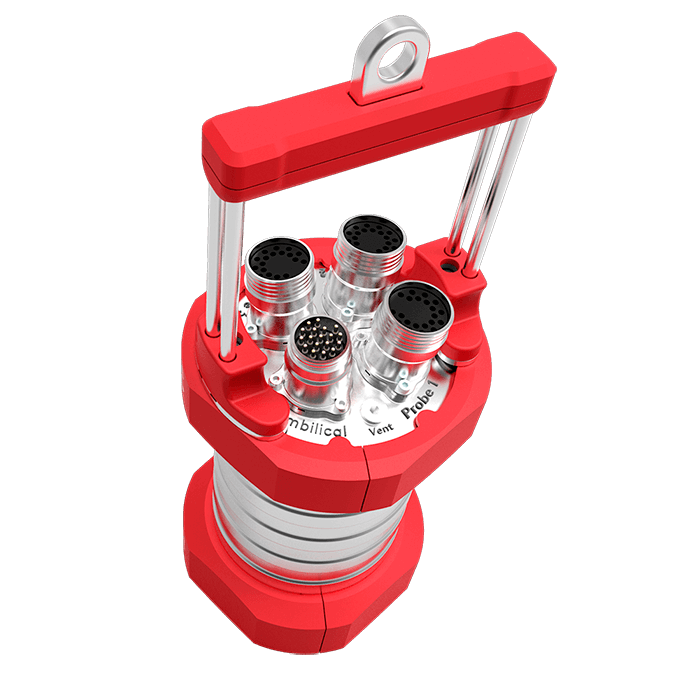

- 3 × SENSU® 2 UW

- U41D/DA: 450 m (1476 ft) (Extended Ethernet)

- Standard length 150 m, up to 3 can be connected in series

- U41D: no

- U41DA: 4 × rows mini

- U41D/DA: VDSL only

- U41D/DA: 300 m (984 ft)

- U41D/DA: Topside unit D

- U41D/DA: 156 × 156 × 430 mm (6.2 × 6.2 × 17 in)

- U41D/DA: 156 × 156 × 292 mm (6.2 × 6.2 × 11.5 in) (without lifting cage)

- U41D/DA: 9.2 kg (20.3 lb)

- U41D: Single

- U41DA: Dual

- 0–45°C (32–113°F)

- 5 m (16 ft)

- Topside: 110 V AC/400 mA U41: 48 Vdc/1A