Details

Complete Multi-Technique Inspection

The powerful Emerald instrument coupled with the advanced automated scanner, WeldXprt supports acquisition using multiple methods including:

- Zonal Discrimination Technique

- Conventional Ultrasonic Testing (UT)

- Time-of-Flight-Diffraction (TOFD)

- Phased Array UT (PAUT)

- Full Matrix Capture (FMC) with Total Focusing Method (TFM)

- Plane Wave Imaging (PWI) combined with TFM

Its automated calibration routines, real-time data analysis, and user-friendly interface streamline the inspection process, reducing setup times and improving production rates. Operators can rely on WeldXprt to meet the most stringent industry standards while minimizing rejection rates and ensuring long-term pipeline integrity.

For those focused on achieving superior weld integrity, WeldXprt offers the next generation of inspection technology, bringing enhanced efficiency and performance to every pipeline project.

With flexible deployment options and all-in-one ultrasound technique capability out of the box, WeldXprt maximizes AUT service providers equipment utilization to tackle a wide range of inspections and configurations.

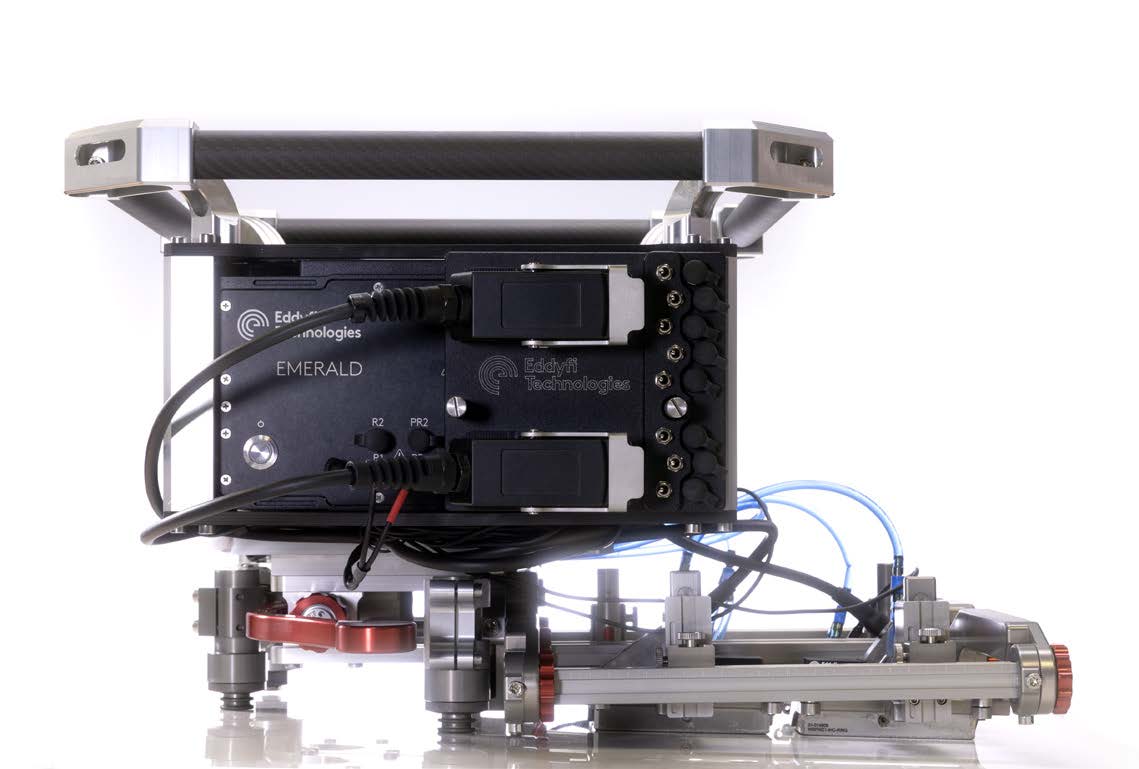

Image: WeldXprt On-board setup. De-mounted options available.

The turnkey solution can be configured either with the EMERALD for both integrated-onboard setup or remote configuration, delivering up to 50% higher data throughput, or with the TOPAZ64 for a de-mounted (remote) configuration, ideal for operators who require flexibility to deploy the instrument across other phased array inspection projects.

Automated Ultrasonic Testing for Pipe Girth Weld Inspection

Automated ultrasonic testing has emerged as the preferred method for pipeline weld inspection worldwide, gradually superseding traditional radiography. Radiography, with its inherent limitations such as poor planar defect detection, absence of vertical sizing capability, safety concerns, and environmental issues, has paved the way for the adoption of AUT. The advantages of AUT are manifold:

- Elimination of radiation hazard, chemicals, and licensing requirements.

- Remarkably short inspection cycle time, ideal for high production rates.

- Enhanced detection and sizing accuracy, resulting in a reduced rejection rate.

- Real-time analysis facilitated by leading-edge inspection software.

- Storage of data and inspection reports in electronic formats for efficient record-keeping.

- Quick feedback to the welding process, contributing to a decreased rejection rate

Advanced Scanner for Reliable Deployment

WeldXprt features a rugged, high-performance automated scanner engineered for demanding conditions.

Key Features:

Band Compatibility:

- Fits standard CRC-Evans and RMS weld bands

- Supports standard 127mm (5in) and narrow 80mm (3.15in) bands for tight cutback applications

Pipe Range:

- Supports 4-8in NPS (114.3-219.1mm) OD pipes with optional drop plate

- Standard support from 8in NPS and up; adaptable for flat surfaces

Control Options:

- Fully operated via WeldXprt software or optional remote control

Probe Capacity:

- Supports up to 10 probes (extension kit required)

Integrated Features:

- Built-in water irrigation system and pump

- Optional battery operation

Scan Speed:

- Up to 177mm/s (6.97in/s)

Umbilical:

- Lightweight, robust design for field mobility

Software: Powered by UltraVision

WeldXprt is based on the robust and field-proven UltraVision® inspection software engine. Featuring a dedicated and streamlined user interface for Pipeline Girth Weld (PGW) examination, it is highly responsive. The workflow has been optimized for this specialized use case, ensuring the highest productivity during inspection campaigns. It features a comprehensive and cutting-edge software suite supporting users every step of the way from design of the inspection technique through to equipment setup, data acquisition, analysis, and reporting. The software has been designed to offer a powerful, flexible, and scalable solution for pipeline weld examination.

Calibration Block Designer

- Built-in calibration block design

- Automatic or manual reflector creation

- Fine adjustment with live update

- Export mechanical drawing for fabrication

- Reflectors pull through directly into zonal builder and calibration routine

Auto Zonal Configuration

- Automatic or manual Zonal Builder for quick beam solving.

- Zonal builder table for instant parameter adjustment.

- Configurable strip chart display.

Beam Simulation

- Simulation for self-tandem and pulse echo modes

- Acoustic Field Simulation for TFM channels

- Automatic ideal aperture calculation

- Verify effective beam parameters

Auto Calibration

- Calibration routine with a single click

- Automatic reflector verification

- Red and Green status for Go/No-Go

- Calibration files saved with weld inspection data

- Assisted 'tap-in, tap-out' routine

Calibration Adjustment

- Highlighted out-of-tolerance reflectors

- Automatic gain and delay correction calculation

- 'Apply Correction' buttons for channel adjustment

- Over trace calculation and verification

- Signal updates in real time with parameter adjustment

Rule-Based Assisted Analysis

- Set rules for indication detection based on criteria

- Assisted application of codes with acceptance or rejection options

- Analyst verification

- Unique detection criteria for each rule

- Indication classification

- Automatic indication boxing and measurement

- Interaction and accumulation

- Weld status Accept/Reject highlighted and stored

Reporting and 3D Views

- Generate customizable weld reports with a single click

- 3D views of weld and volumetric UT data

- Significant time savings in analysis and reporting

Instrument Platform: Emerald

Emerald is the high-performance, multi-channel phased array platform integrated with WeldXprt:

- 64/128PR + 2UT high performance phased array system

- FMC & PWI data acquisition with latest TFM processing and imaging

- High speed multi-channel configurations

- Industry leading signal quality and power

- Seamlessly integrated with WeldXprt & UltraVision 3 platforms

Revolutionize Your Pipeline Inspections. Protect Your Investments.

Unlock the full potential of your pipeline operations with Eddyfi Technologies' AUT pipe girth weld solution. Experience the speed, precision, and confidence that come with using the most advanced inspection technology on the market. Ensure the safety and reliability of every weld, every time.

Don't settle for less—take the next step in securing your pipeline integrity.

Request a quote

Benefits

Ultra-efficient workflow and acquisition speed for rapid inspection and sentencing

Dedicated pipe girth weld interface powered by the UltraVision® software engine with long history and global support

Mission-critical reliability trusted by leading industries including oil & gas, nuclear power, defense, and aerospace

Support for multiple techniques—Zonal PAUT, TOFD, PWI, TFM/PCI for high-speed assessments

Real-time results and rule-based assisted analysis for streamlined decision-making

Download

- {{item.moduleNameDisplay}}

- No results found

- View more results

-

{{group.moduleNameDisplay}}

- No results found