UltraVision® 3 Classic software manages ultrasonic testing (UT) signal acquisition, displays real-time imaging of these signals, and provides online and offline data analysis. UltraVision offers many advanced features and tools that improve the efficiency and accuracy of UT inspections.

UltraVision drives all phased array UT and conventional UT systems. In data analysis mode, it supports legacy file formats (DAT, RDT) in addition to the new UVData and BeamData formats.

Download UltraVision ClassicDetails

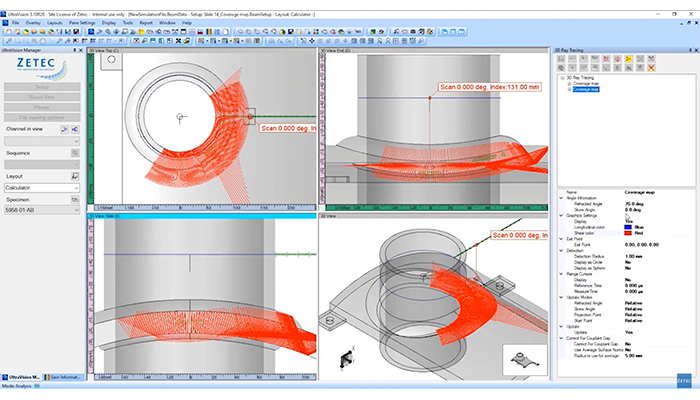

3D work environment

The integrated 3D work environment allows you to create your actual inspection configuration in UltraVision 3 Classic and perform ray tracing with coverage mapping to determine your detection capability and inspection coverage.

The ultrasonic inspection software is intuitive and allows users to design and simulate an inspection easily. Inspection parameters and results are delivered in a comprehensive report.

UltraVision supports many advanced ultrasonic inspection techniques and methods. It provides value, support, and critical inspection processes when reliability, performance, and ease of use are required.

Technique development

The development of the inspection technique is the start of every ultrasonic inspection. Basic inspection techniques can be drafted manually or on third-party software, but this is time consuming and requires transfer. UltraVision provides an extended set of capabilities for complex and custom geometries.

- From basic to complex geometry management

- Custom geometry handling

- Scanner creation tool

- Overlays

- UV technique

UltraVision features an advanced focal law calculator, standard for the entire Eddyfi Technologies' UT portfolio. It can handle probes with up to 256 elements and takes into consideration the embedded probe, the wedge, and the material database.

Visual feedback is provided on focal law generation. Focal law calculation supporting flat and cylindrical geometries is easy, fast, and accurate to ensure that probes are positioned optimally for the inspection. The focal law calculator supports all advanced ultrasonic inspection techniques, including phased array pulse echo, pitch and catch, tandem TFM and PWI, plus conventional time-of-flight-diffraction (TOFD). UltraVision supports flexible probes that can adapt to irregular surfaces requiring inspection. UltraVision can calculate focal laws to match the surface profile.

UltraVision will design a probe to meet the application requirements, assessing the theoretical parameters, calculating beam parameters, and providing a 3D simulation of the acoustic beam. It will also simulate beam behavior if any of the channels are defective. Additionally, calculated wedge parameters can be exported to facilitate wedge manufacture.

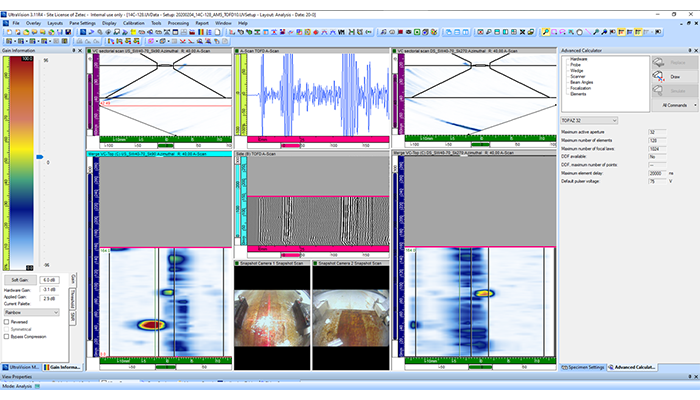

Data acquisition

When it comes to setup building, calibration, and data acquisition, UltraVision can handle it all.

Setup Building: UltraVision can effectively take care of user rights management (from individuals to groups), ensuring the inspection integrity. UT parameter, mechanical, and screen view settings can all be restricted to defined users or groups.

Calibration: Various tools are available to check the calibration of mechanical and UT parameters. Plus, automatic probe detection identifies connected probes, reads probe parameters, serial number, and tracks any probe changes.

Data Acquisition: UltraVision acquires all the relevant data necessary for accurate and reliable inspections. This data is stored in a data file that can reach up to 20GB and can be filed or exported according to user requirements.

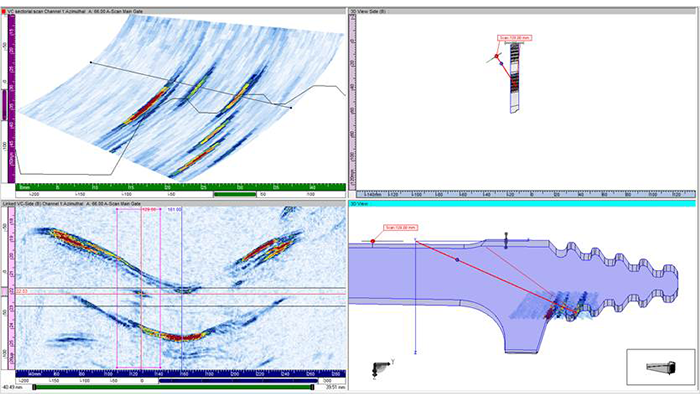

Data analysis

UltraVision’s powerful data analysis features provide an inspection advantage.

Views and Axis: Provides a range of advanced views which can be uncorrected, volume corrected, or three-dimensional. The software can also convert between Cartesian and Polar coordinate systems and can convert Linear to Logarithmic data.

Analysis Support: A large set of tools is available to assist with data analysis and sizing indications.

File Management: Data can be filed or exported according to user requirements.

Processing Tools: UltraVision also features a range of processing tools offering various data display formats and corrective processing. The original raw data is never compromised.

Parameters: All UT and mechanical parameters can be reviewed and displayed in information fields. Customized information fields are filed through dynamic links to Excel where specific calculations can be performed.

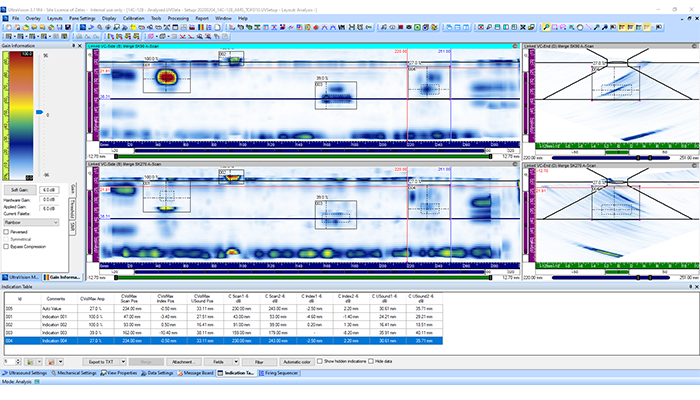

Reporting

With UltraVision, reporting is highly flexible and powerful. Indications are automatically published in an indications table that can be exported to Excel or a complete report.

Indications are directly plotted on a 3D view of the inspected specimen. Additional configurable user fields can be created to provide more information in the report. Best of all, a wide range of predefined reports are available to facilitate the reporting process.

Download UltraVision ClassicBenefits

Specimen settings

Basic to complex geometries management: UltraVision contains a comprehensive bank of configurable predefined specimens including connecting pipes, cruciform joints, T and L joints.

Custom geometry handling: UltraVision features several ways to create specimen geometry. It has a tool to manually create specimen geometry and an onboard specimen geometry generator which uses the profile scanned from a mechanical profile gauge. 3D custom specimens can also be produced from SAT files. Finally, it is possible to import a file from ESBeamTool.

Overlays: Configurable welds can be added to specimens such as V, modified V, X, J, K. Weld profiles can be imported from ESBeamTool or a DXF.

UT data acquisition

UT data acquisition: can be 8, 12, or 16 bits and the data file size can be up to 20GB.

A-scan length: can be up to 256000 points per A-scan, and every elementary A-scan is captured.

Merged views:UltraVision is capable of creating and displaying merged views in real time.

Mechanical setting: allows single point (free running), one-line scans, and bidirectional, unidirectional, helicoidal, and polar sequences.

Motorized acquisition: The probe’s positions are controlled from the ZMC2, ZMC4, or MCDU motion controllers. It is possible to collect position information from up to six encoders, and focal laws can be adapted depending on the probe position. The start, stop, and pause data acquisition functions are directly controlled from UltraVision 3.

Setup creation

Scanner Creation Tool: The scanner creation tool allows a user to simulate the probe position and related UT data on 3D component.

Beam Simulation: Beam simulation allows you to compute, visualize, and characterize the energy distribution in the acoustic beam generated by any given probe, including single element (conventional UT), 1D linear array, and 2D matrix arrays.

Advanced PA Calculator: The focal law calculator supports all advanced ultrasonic inspection techniques, including phased array pulse echo, pitch and catch, tandem mono and dual, and conventional TOFD.

Automatic Probe Detection: Automatic probe detection detects and identifies connected probes, reads probe parameters and serial number, and tracks any probe changes.

Calibration Tools: Calibration tools calibrate the encoder, wedge separation and velocity for TOFD probes, PA wedge delay, sensitivity, and TCG. Individual elements are checked in PA arrays. The calibration block is defined and a calibration check report is generated.

Analysis tools

Sizing Tools: Slicing cursors allow easy measurement while the ability to draw contours around indications assists in manual sizing. An automatic drop sizing tool allows sizing of the indication within the drawn contour using the dB drop method. Echo dynamic sizing is also available.

Assisted Analysis: Analysis can also be carried out by automatically screening the entire data file and indicating the areas of interest based on specific user-selected criteria.

3D Data Plotting: By synchronizing A-scans and 2D and 3D data, the software can plot indications and create 3D images.

Volumetric Processing: Volumetric processing involves volumetric merging, and smoothing to produce a software C-scan. A 2D specimen overlay in top, side, and end views can also be applied.

TOFD Processing: Tools are available for hysteresis correction, geometric echo removal, and TOFD Processing (LW Synchronization, LW Removal, SAFT).

Views

View Layout: User rights also extend to deciding how data is displayed on the screen. Users can select sectorial, scrolling, volume corrected (B, C and D), polar, A-scan, FFT, 3D, amplitude, or time-of-flight C-scans.

Customization: Predefined custom layout management can also be selected to view customized properties such as envelope, smoothing units, overlays, and view linking where the cursor movement can be linked. There is no limitation to the number of channels displayed.

Color Palette Editor: A color palette allows amplitude and TOFD data to be displayed according to user preference.

Reporting

Indication Table: The indications table is automatically populated by selected information fields and can be exported to a text file.

User Information Fields: Configurable user fields can be created to provide additional information in the report.

3D Views in Reports: Indications are directly plotted on the 3D view of the inspected specimen.

Download

- Train Axle Inspection Applications Brochure

- Wet Hydrogen Sulfide Damage Applications Brochure

- High Temperature Hydrogen Attack (HTHA) Applications Brochure

- Corrosion Mapping Applications Brochure

- Advanced Weld Inspection for Carbon Steel Applications Brochure

- Advanced Weld Inspection for Boiler Tubes Applications Brochure

- Advanced Weld Inspection for Austenitic Steel Applications Brochure