QuartZ is the answer for complex and high-speed inspections and is optimally designed for the oil & gas, manufacturing, and transportation markets. QuartZ achieves an excellent balance between speed, power, and flexibility for the most complex inspection environments and applications.

QuartZ is ideal for inspecting tubes, pipes, plates or forgings, composite materials as well as train wheels, rails, and axles.

When combined with UltraVision software’s legendary power and software development kit (SDK) flexibility, QuartZ is the perfect choice for creating custom inspection solutions.

Details

Meet your specific needs, today and in the future

UltraVision® 3 Classic controlled: Tap into the full power of QuartZ. Offering a 3D work environment, UltraVision delivers the full inspection process within the same software package, from inspection design to advanced analysis and reporting.

Scalable: Up to 10 QuartZ units in parallel controlled by the same UltraVision. Almost no inspection configuration is too big.

Easy integration: Multiple QuartZ units can be synchronized in a simple cable configuration. Changing from a tabletop to 480-millimeter (19-inch) rack mount configuration is as simple as adding the included mounting brackets.

Made tough for harsh environments: QuartZ can be installed close to the probes, reducing cable length. No air conditioning is needed, saving in project complexity and installation costs.

Increase inspection productivity

Parallel firing capability: QuartZ supports 32:128 or 2×16:64 configurations for two simultaneous apertures on one or two probes.

Integrated probe splitter: Connect two phased array probes without any additional accessories.

High power phased array channels: QuartZ incorporates a real 100V pulser for the phased array channels, ideal for the inspection of very thick or difficult to penetrate materials.

Two powerful conventional UT channels: A full inspection configuration with two PA probes and two UT probes only needs one simple instrument.

High data throughput: QuartZ can deliver up to 30MB/s of data throughput making all the difference for demanding applications.

Automatic probe detection: When using Eddyfi Technologies' probes, QuartZ automatically detects the probe(s) and connection to help ensure you are using the right probe while simplifying traceability in the reporting process.

Time reversal support: Inspect various geometry-changing surfaces of composite materials without complex surface following mechanics or previous knowledge of the exact part shape.

Industries

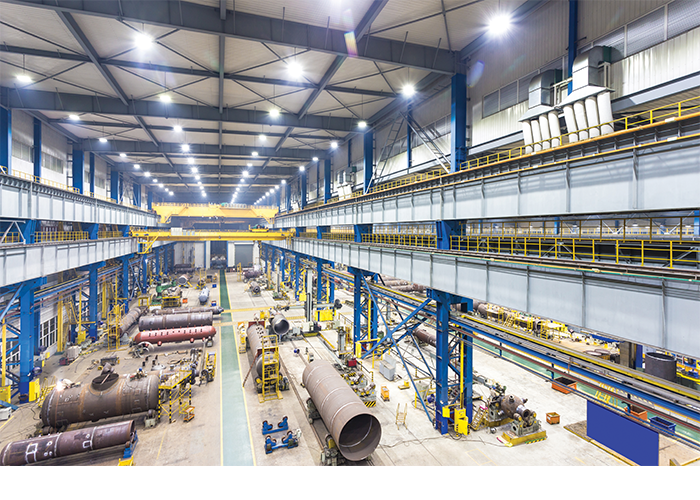

Manufacturing

Metal manufacturing requires providing high-quality parts for a very large range of applications. Cycle time minimization is critical for the optimization of production rates. QuartZ offers the right tools and scalability to address most applications.

Tubes, Pipes and Plates

QuartZ allows creating the right solution for the inspection of tubes and pipes, plates, or forgings. Inline and offline applications are ideal for QuartZ, easily creating a complex inspection configuration when required.

Aerospace

The increasing use of composite parts that have complex and variable geometries creates inspection challenges. Time reversal is a real-time and adaptive technique that does not require knowledge of detailed component profiles. QuartZ and time reversal together simplify the inspection process of complex composite parts for rapid and reliable PAUT inspections without the need of complex surface following mechanics or previous knowledge of the exact part shape.

Transportation

The transportation industry is especially concerned by security. Train wheels, axles, and rails need to be inspected at manufacturing and at regular intervals. QuartZ provides the tools for building the right solutions.

Want to see QuartZ in action? Book a demo!

Specifications

INSTRUMENT

490 × 420 × 90mm (19.3 × 16.5 × 3.5 in)

8.34 Kg (18 lb)

No

120 VAC or 240 VAC

50 Hz or 60 Hz

75 VA

PHASED ARRAY

32:128 PR

Up to 32 consecutive elements. Up to two apertures of 16 consecutive elements

2 x ZPAC connector (custom ZIF with latch). Allows connecting 2 probes without splitter. Automatic probe recognitions (with Eddyfi Technologies' probes).

2 channels (in Pulse/Echo or Pitch/Catch configurations

PULSER

25 ns to 500 ns

35 V to 100 V

50 V to 200 V

DATA ACQUISITION

Up to 16,384 points

1024

1, 2, 4, 8, and 16

1, 2, 4, 8, and 16

Up to 20 kHz

2 beams

16384

4 gates + 1 synchronization gate

Up to 30 MB/s

20 GB

25 MHz, 50 MHz or 100 MHz

500 kHz to 18 MHz

16 bits

Analog / Digital band-pass, high-pass and low-pass

70 dB (analog) + 30 dB (digital)

70 dB (analog) + 24 dB (digital)

CONNECTIVITY

Ethernet 1000 Base-T

2 axes (quadrature, clock direction)