Detecting Corrosion in Aluminum with Eddy Current Array Technology

Corrosion is everywhere and aluminum is no exception. Whether used in the petrochemical, the power generation, or the aerospace industry, aluminum is subject to degradation. Without a doubt, there is a real need for a reliable and high-precision Non-Destructive Testing (NDT) method.

In many situations, one must detect and assess the extent of corrosion damage without having direct access to the region of interest. Indeed, assessing wall loss and pitting on the far side of an aluminum layer is key in a number of situations.

The present document highlights the capabilities of Eddy Current Array (ECA) technology using a particularly interesting application: corrosion detection in the storage tanks of nuclear power plants. The following describes how the technology is used to examine this important asset, which plays a critical role in the safe operation of nuclear plants.

The Challenge

- Detecting corrosion defects such as pitting and wall thinning on the far surface of an aluminum tank floor.

Storage tanks vary in size, shape and material. In the current situation, an aluminum tank with a slightly concave floor (approximately 5.2 m [17 ft] in diameter) was in need of inspection. As in most cases during in-service inspections, the far side of the aluminum plate was not accessible. This called for a solution capable of scanning through the floor plates in an effort to detect and characterize corrosion-related defects such as pitting and thinning. An enhanced technique was needed in place of conventional NDT methods such as Ultrasonic Testing (UT) or single-channel Eddy Current Testing (ECT).

In the application herein, the examination was originally performed with UT, which required couplant, a crew of four to five technicians and a significant amount of time because of the small active surface of the transducer (6.35 mm or 0.25 in).

Furthermore, a wide ECA probe would need to:

- Adapt to the tank floor’s curvature and other geometric features

- Offer sufficient penetration to scan through thick aluminum (6.35–7.94 mm or 0.250–0.313 in)

- Be robust enough to withstand extensive use

The Solution

- Using eddy current array technology with a semi-flexible probe to scan through aluminum, detect corrosion defects and characterize them.

ECA technology uses several individual coils, grouped together in one probe. The coils are excited in sequence to eliminate interference from mutual inductance (something referred to as multiplexing). So doing, the coils work together to scan a wider inspection area than conventional ECT probes, which drastically cuts down on the time required to inspect an entire tank floor.

The absence of couplant, inherent to eddy current testing, is also a natural advantage of the solution over UT.

The solution developed to answer this challenge consists of three elements—the Ectane®, a compact, rugged, battery-operated ECA data acquisition unit; Magnifi®, acquisition and analysis software for graphical display (C-scan), record keeping, and reporting; and, finally, because of the non-linear geometry found in this application, a semi-flexible probe whose active surface could match the tank floor’s geometry.

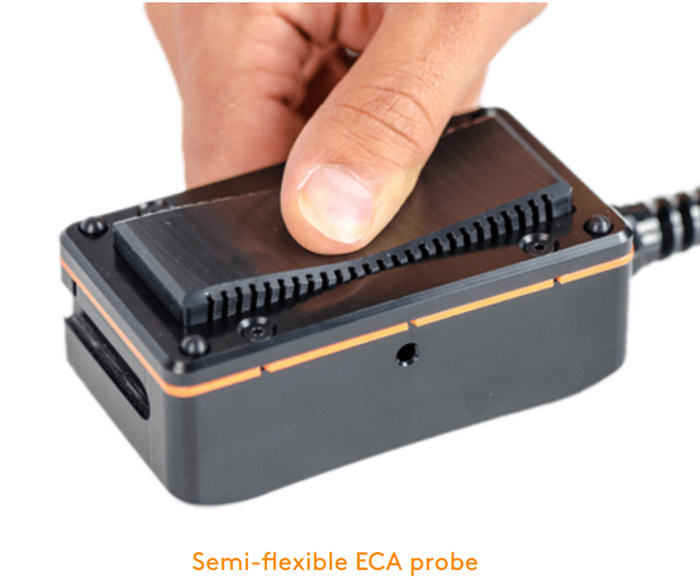

The ECA probe developed for the application has a flexible active surface 128 mm (5.04 in) wide adapting to slightly convex or concave geometries. The array features 33 coils, distributed in two rows, and uses multiplexing for enhanced performance.

The coils, 6 mm (0.236 in) in diameter, are perfectly matched to cover a lowfrequency range of 0.6–20 kHz with a central frequency of 5 kHz. This design ensures excellent penetration, reaching the far side of the aluminum tank floor.

Semi-flexible ECA probe

A calibration plate was used to validate the probe’s performance. To simulate both localized pitting and plain corrosion, it has a series of flat-bottom holes (FBH) ranging from 1.59 mm (0.063 in) to 12.7 mm (0.5 in) in diameter and 10% to 80% of the plate’s thickness.

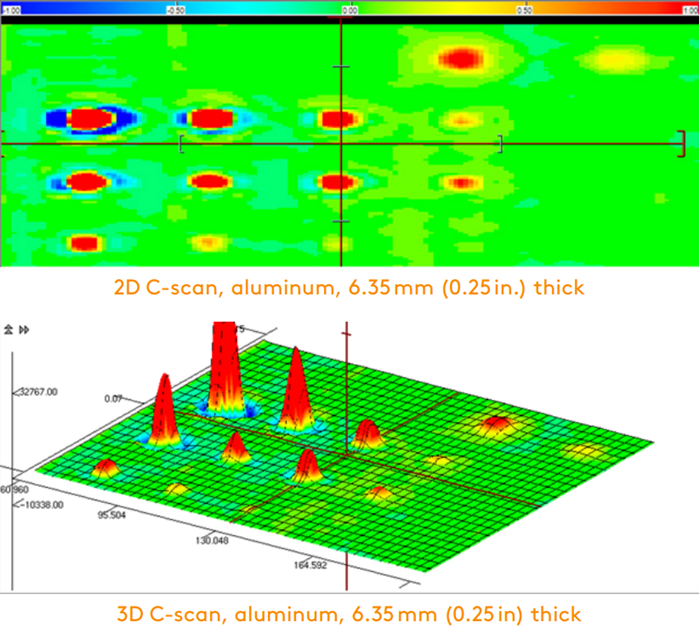

Thanks to Magnifi, it’s easy to use the phase angle to assess the extent of corrosion, discriminating between nearsurface and more distant defects. In addition to the traditional impedance plane, ECA technology offers advanced imaging capabilities. Indeed, Magnifi can generate 2D and 3D C-scans, which proves extremely useful when interpreting signals. Scanning the calibration plate with the ECA probe yielded the following results:

The ECA probe can clearly detect pitting-like indications (down to the 1.59 mm [0.063 in]) FBH at 40% thickness) or thinning-like indications (down to the 12.7 mm [0.5 in] FBH at 10% thickness). These results proved to be superior to those of the previous examination method.

The solution was deployed on-site and led to the discovery of very degraded tank floor plates. The entire ECA inspection of a typical tank floor was performed in about a tenth of the time taken with the original UT inspection procedure, and was carried out by a single technician.

Benefits

- Fast detection and discrimination of corrosion defects with full data recording and archiving.

The solution developed by Eddyfi Technologies to meet the challenge of corrosion detection in nuclear power plant storage tanks has several benefits, useful to other industries and applications as well:

Rapid scanning of large regions of interest

Improved versatility, adapting to curved or irregular surfaces

High-precision assessment of localized indications (e.g., pitting) and general degradation (e.g., thinning)

Easier interpretation with C-scan imaging

Full data recording and archiving capabilities

Eddyfi Technologies develops a variety of products, of which the ones presented here are only a few. We have the expertise and flexibility to engineer solutions for the most challenging applications.