The Eddyfi Remote-Field Array (RFA) tube probe family brings high-resolution C-scan imaging to ferrous heat exchangers (HX) at conventional Remote-Field Testing (RFT) acquisition speeds. The technology is powered by a patent pending, low-frequency multiplexing protocol.

Features

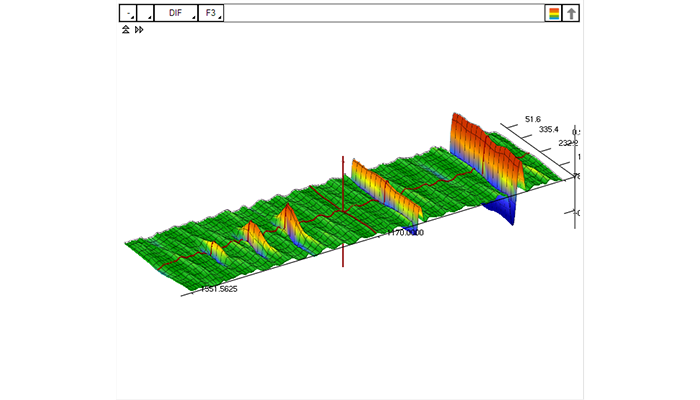

- High-resolution C-scan imaging for greater insight on defect morphology

- Better detection of defects close to external features compared to conventional RFT

- Same pulling speed, cleaning, and fill factor requirements as conventional RFT

- Centering devices maintain constant liftoff in field conditions, leading to improved detection

Details

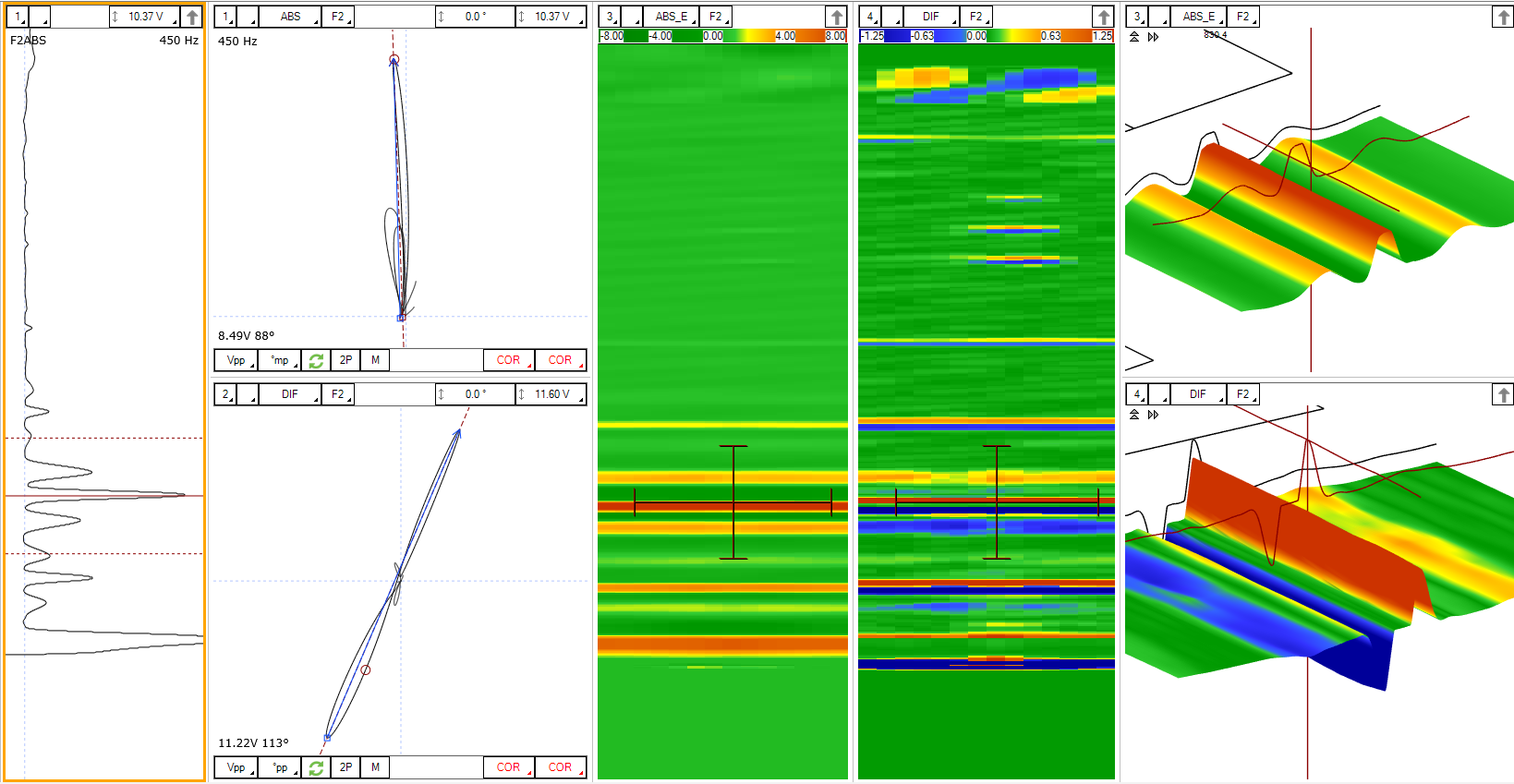

High-resolution C-scan at RFT speed

The RFA probe design combines a high-density array of coils with conventional bobbins featuring dual drivers. Powered by a patent pending low-frequency multiplexer, this solution enables the generation of high-resolution C-scan images, offering greater insight into the defect morphology and an overall improved assessment of the bundle.

Designed with up to 30 coils, the probe family supports inspection of heat exchanger tube sizes ranging from 15.8 mm to 31.75 mm (0.625 in to 1.25 in).

Learn more

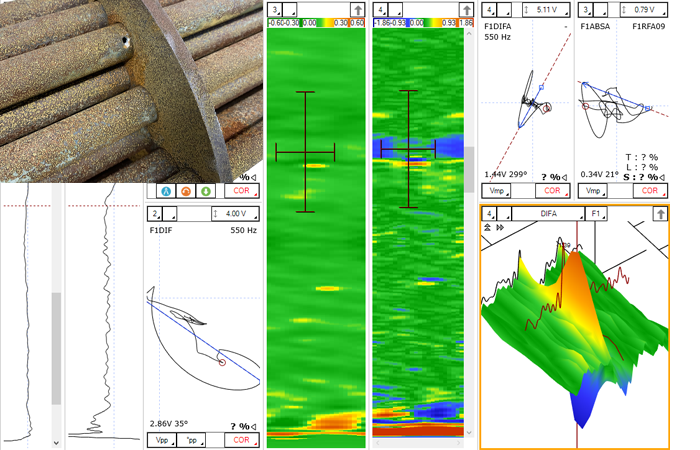

See defects closer to external features

By design, conventional RFT probes offer a very limited performance near external features such as support plates and tubesheet. With RFA, the array of small sensors increases sensitivity, enabling detection of pits and small defects close to tubesheet and support plates.

In general, RFA improves detection coverage, reducing blind zones surrounding external features by up to 75%, when compared to standard RFT inspections.

Same RFT inspection requirements, better sizing

RFA probes perform inspections at the equivalent speed of conventional RFT (typically around 300 mm/s or 12 in/s), and can be used with the same inspection preparation requirements for cleaning and fill factor. The conventional, absolute, and differential channels are simultaneously acquired and displayed.

The centering devices, engineered for carbon steel inspections and integrated with the probe design, lead to improved sizing capabilities on both the standard and array signals.

Data analysis

- Magnifi software required: PRO, 5.1 and higher for acquisition and analysis

- ABS signal representation: Impedance or voltage plane

- Number of frequencies: 2

- Driver activation: independent

- Conventional and array (C-scan)

Specifications

78% or more

11.0 mm (0.433 in) to 23.0 mm (0.906 in)

300 mm/s or 12 in/s

50 – 2,000 Hz

2

Ferrous (designed for carbon steel)

9 mm (0.375 in) or 12.7 mm (0.5 in) strong, premium, non-kinking nylon

41-pin

Stainless steel

Ceramic feet with foam induced pressure

Ectane 3-E64RNM(I) or Ectane 3-E128RNM(I)