Maintain Uptime's Data with Optimize Cooling System Assessment

Ask an expertData centers can be found everywhere and have become modern day fortresses. In these strongholds, information is a treasure that is well guarded yet accessible all the time by users, often worldwide. Data centers need rigorous procedures and infrastructures to guarantee maximum uptime and security of data.

The Uptime Institute provides certification to data centers by judging and auditing their processes. According to a recent Uptime Institute survey1, 34% of surveyed centers are being operated beyond their expected lifecycles. From the same surveyed group, 75% believed that this practice increased the odds of an outage and resulted in an increase in operating costs. This means that proper maintenance is critical. When it comes to infrastructure, one of the critical systems is the cooling technology. If a serious fault to the air conditioning system were to occur, consequences range from potential downtime to a serious loss of data.

The cornerstone of proper data center cooling technology is typically a shell and tube heat exchanger, often called a “chiller”, and this critical asset needs to be inspected properly.

The Challenge

Establish bill of health for one of the data center’s primary assets and offer a comprehensive report in a timely manner with optimal precision

Chiller tubes are subject to various damage mechanisms that can create losses including premature localized pitting, extended thickness erosion, and/or cracks near the areas of expansion caused by the various fluids involved; therefore, these flaws need to be detected and properly monitored.

Eddy current based inspection techniques are the norm for assessing the integrity of the tubes. When performed onsite, the procedure can be somewhat archaic. To accelerate the inspection process and keep costs to a minimum, the tube bundle is generally only partially inspected, and reports are often unstructured, provided on-the-spot, with no recording of the data.

Partial inspection means a partial overview of the asset which could lead to false conclusions. Furthermore, eddy currents are often perceived as a complex and highly operator dependent inspection technique.

There is a need from operational management for a better understanding of the damage mechanisms and the state of their cooling systems in order to prolong longevity.

1Andy Lawrence, Uptime Institute data shows outages are common, costly and preventable (Focus, June 2018).

The Solution

A complete inspection solution for air conditioner tubing including the most modern instrumentation, software and probes to detect all relevant flaws in chiller tubes

Eddyfi Technologies offers a complete tubing inspection solution for water-cooled chillers. It represents the state-of-the-art in terms of eddy current testing for chiller tubes.

By using the Reddy® AC system designed for Air Conditioner (AC) integrity assessment, a technician can quickly scan through a whole exchanger and generate an informative report that gives valuable insight on the state of the asset.

The complete solution is comprised of three key elements:

- Reddy AC & Tubing ECT system for acquisition and analysis,

- Air Conditioner (AC) probes specifically designed for this application,

- TubePro™ software for comprehensive reporting.

Eddyfi Technologies has solutions for all asset integrity needs. Feel free to contact us with your challenge!

Learn moreBenefits

- Repeatable data results provide the information required for audit and insurance purposes, and peace of mind to operators who depend on the continued operation of cooling technologies

Eddy current testing is the most reliable way to assess tubing defects in chillers. Unfortunately, the few systems used in the field are old technology which offer small, low-resolution display, very limited features especially for data analysis which is critical, poor control ergonomics, plus they require external power and are not waterproof. They also lack easy-to-use embedded software with efficient reporting. Thanks to a modern approach, the Eddyfi Technologies' solution offers a simple user interface and assistant analysis tools to make it easier than ever for anyone to inspect AC tubing while getting the best detection capabilities. The Reddy AC is lightweight, water resistant, battery operated and designed with a built-in touch screen so that it can easily be transported wherever the chiller is located, even in tight places. With its simplified and streamlined user interface, it is easy to assess a typical chiller. All data is recorded which makes it perfect for auditing and insurance purposes.

Combined with the best sensor configuration on the market, this solution can detect both internal and external flaws such as small pitting, corrosion, and general wall loss everywhere along the tube in a single pull. Furthermore, our probes have been developed to reduce the effect of chiller tube grooves on the signal and can detect cracks in the land area.

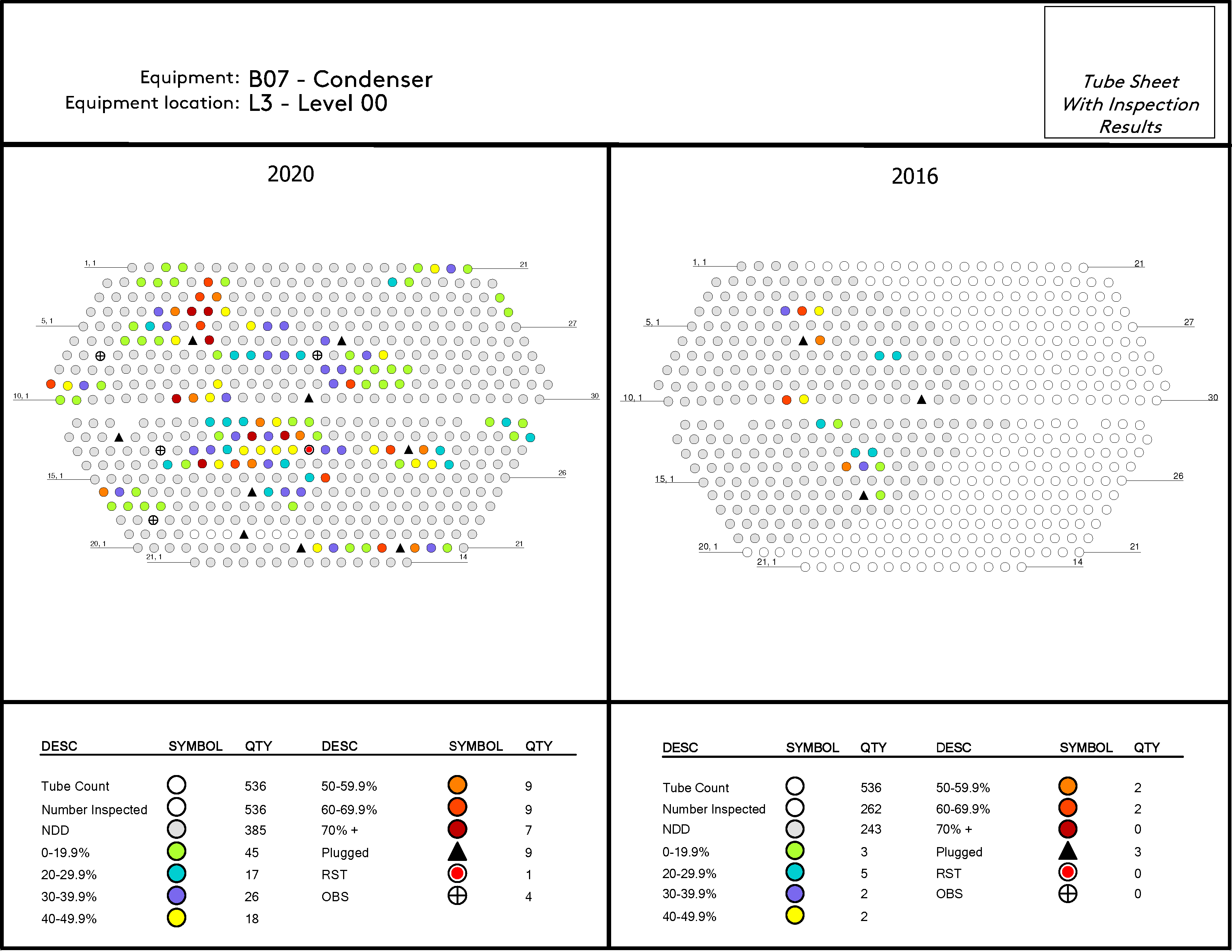

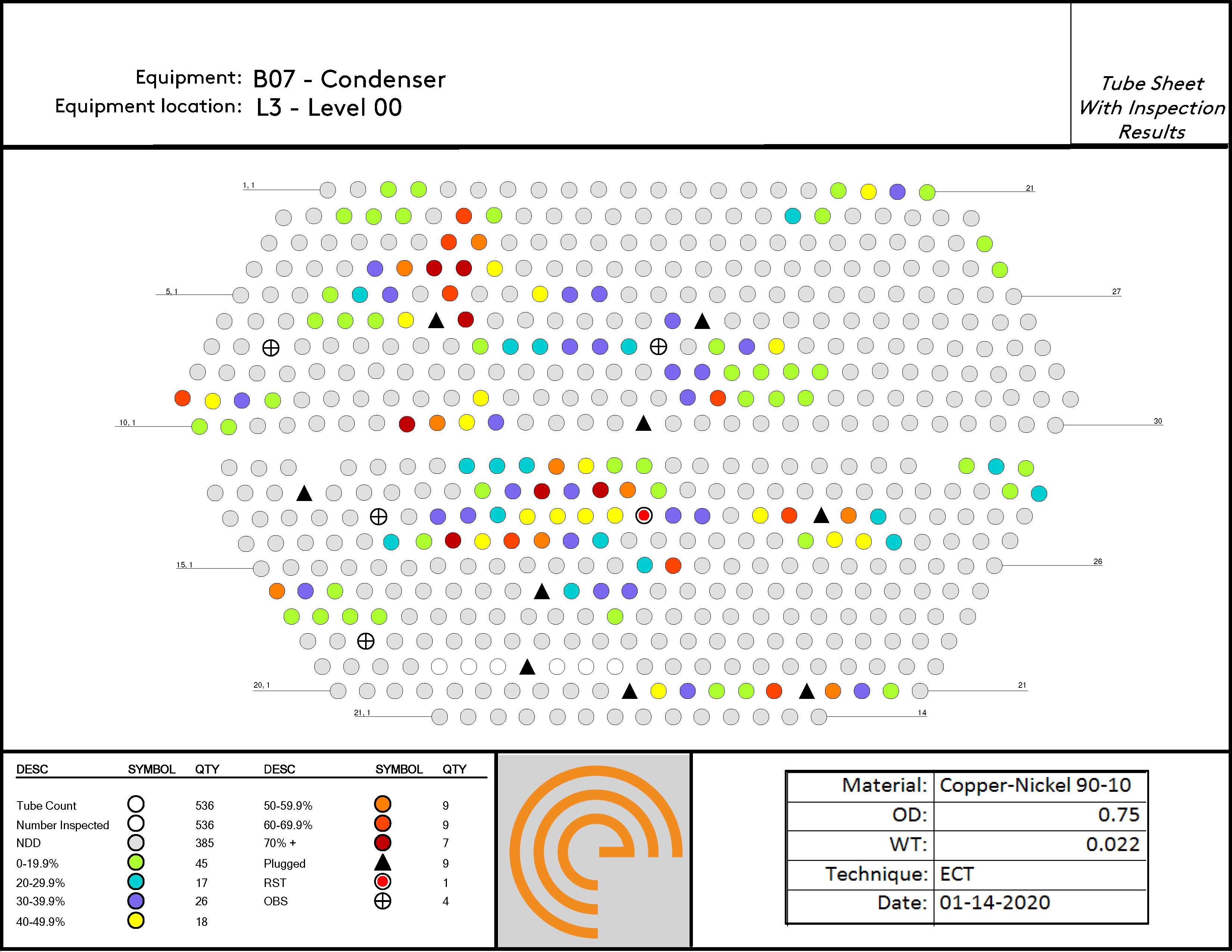

Once data is acquired for analysis, TubePro offers the best tools in the industry to present results in an insightful report. By creating a report template, users can consistently produce a comprehensive report that shows 2D tubesheet mapping of the defects as well as 3D modelling of the chiller. Historical data analysis also offers a better comprehension of the evolution of indications and allows operational managers to be more forward thinking in their approach and better manage their critical assets.

With all these tools, operators have increased insight and can make the best decision when it comes to their chillers. Simply put, the Eddyfi Technologies' solution makes it easier to more accurately and more rapidly detect any type of defect that can prevent the optimal use of industrial air conditioning systems.