Inspecting Lead-Clad Pipes with Pulsed Eddy Current

The most effective way to minimize the risk of unnecessary shutdowns and accidents caused by Corrosion Under Insulation (CUI) is to periodically inspect the condition of insulated equipment and piping.

The Challenge

Reliably detecting CUI in the presence of lead sheathing without stripping pipes.

Industrial installations sometimes generate noise loud enough to be considered hazardous for worker health and safety. Turbulence caused by fluids and vibrations in pipes are two major sources of industrial noise. Where noise control is important, it is not uncommon to find pipes wrapped in noise-dampening layers between the conventional insulation layer and the weather jacket.

Noise-dampening layers typically include an acoustical barrier of dense, soft material muffling sound and lessening vibration. Up to end of 20th century, lead sheets were the go-to method of performing this task because they are flexible, easy to wrap around pipes, and offer excellent noise attenuation properties. Despite concerns over lead exposure and regulatory restrictions, it is still quite common to find lead-clad pipes in installations over 15 years old.

Common techniques used to look for CUI (visual inspection, phased array UT, etc.) involve time-consuming and costly stripping. One common way to avoid stripping is using radiography. However, due to its high density, lead is particularly effective in blocking X-rays, seriously hampering the use of the technique.

The Solution

Using an inspection technique unaffected by the presence of lead—pulsed eddy current.

51mm (2in) insulation and aluminum weather jacket

51mm (2in) insulation, 1mm (0.04in) lead sheet, aluminum weather jacket

Lead is weakly diamagnetic and poorly conductive, so it does not interfere with Pulsed Eddy Currents (PEC), making the Lyft® PEC solution an excellent option to inspect lead-wrapped pipes for CUI without stripping the cladding and weather jacket.

Lyft is a high-performance system that reinvents PEC. This complete solution comes with a state-of-the-art portable instrument and a comprehensive set of probes.

Lyft can scan wall thicknesses up to 101.6 mm (4.0 in) through insulation up to 305 mm (12 in) thick, over aluminum, stainless steel, and galvanized steel weather jackets.

Lyft also features real-time C-scan imaging and A-scan analysis, grid mapping and dynamic scanning (unique to the solution), and it can acquire data at up to 15 readings per second.

Probe shoes enable operation on surfaces as hot as 120°C (248°F). They also attenuate the vibrations induced by pulsed eddy currents in galvanized steel weather jackets.

SmartPULSE™ technology enables automation and advanced algorithms that remove operator-specific dependence. SmartPULSE automatically optimizes pulser and receiver parameters (gain, duration, time gates, filters, etc.). It also optimizes Wall Thickness (WT) measurements, which ensures the best performance and repeatability, while limiting the need for advanced knowledge of PEC.

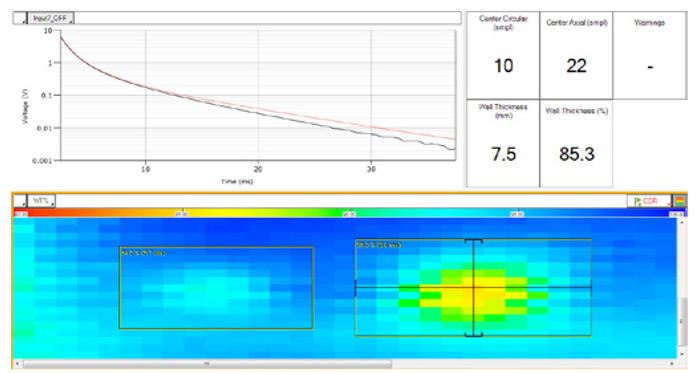

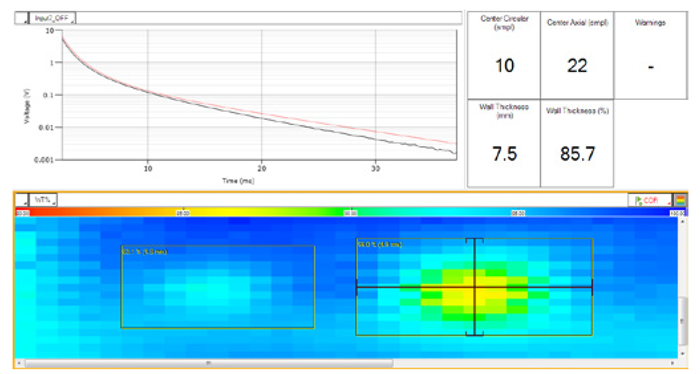

The impact of lead cladding was assessed experimentally on a reference pipe featuring two square defects with a remaining wall thickness of 60% ±5%, 6.5 cm2 (1 in2) and 26 cm2 (4 in2) in area. The first C-scan shows results from a pipe covered with 51 mm (2 in) thick insulation and an aluminum weather jacket. The second C-scan shows results from the same pipe covered with a 0.8 mm (0.03 in) lead sheet under the aluminum jacket.

The two C-scans are essentially identical. So, it is safe to assume that the lead sheet does not decrease the measurement’s signal to-noise ratio.

In addition, yellow values on the C-scans show that the compensated wall thickness tool successfully finds the reference wall thickness value within 5% even if both defects are smaller than the probe’s footprint.

Learn moreBenefits

- Faster, more accurate, less user dependent solution that does not require stripping to detect CUI over lead sheathing.

The Lyft solution’s benefits are obvious:

No stripping

Unlike other inspection techniques, PEC does not require stripping the insulation, fireproofing, or coatings from the surface under test, making it faster and more cost effective.

High-quality data

Despite the presence of lead, where radiography is ineffective, acquired data shows no significant signs of attenuation or deterioration compared to data acquired without lead.

Lesser operator dependence

Lyft automatically optimizes parameters and measurements, ensuring repeatability and performance.

No H&S issues

Unlike radiography, PEC does not pose any hazard to the health of its users or the environment it is used in.

Easy deployment

The entire solution is portable, light, compact and fast to deploy for improved productivity.