Complete and Cost-Efficient Solution for Corrosion Mapping Capital Assets

Ask an expertAnyone operating in the non-destructive testing industry understands that more than one tool is required for inspection. Even with similar applications, certain variables can impact coverage. It is common for an inspector to encounter a variety of critical components and infrastructure requiring condition assessments in one job. Regardless of the unique conditions for the range of assets requiring inspection, it is imperative that the inspection data results are repeatable, actionable, meaningful, and preventative. To consistently meet this goal, industry should seek a trusted equipment solutions provider dedicated to supplying clients and stakeholders with a turnkey solution that supports application deliveries.

The Challenge

Find a cost-effective solution that can cover a broad range of phased array corrosion mapping requirements.

Technicians performing phased array corrosion mapping on vessels, dome ends, and associated pipework have to contend with a number of challenges including varying wall thicknesses, multiple diameter pipelines, restricted access, as well as non-uniform component configuration. Multiple devices are necessary in order to collect the accurate data essential for effective and efficient risk management programs. With these considerations in mind, it is obvious that the financial burden of acquiring powerful and dependable equipment may pose a challenge in itself. It is therefore imperative for those operating in the non-destructive testing sector to research synergistic hardware and software solutions that maximize utilization through multifunctionality for greater cost effectiveness.

The Solution

New and improved commercial technology offered as integrated package provides complete coverage of assets.

Eddyfi Technologies offers comprehensive corrosion mapping packages that leverages a range of Semi-Automated & Automated corrosion mapping and weld inspection scanners. These tools provide unparalleled flexibility and efficiency for phased array corrosion mapping of pipework, vessels, and other critical assets.

The NDT Sweeper is a versatile manual 2D encoded scanner designed for quick ultrasonic testing examinations. It can scan both flat and curved surfaces, making it ideal for corrosion mapping and weld inspections. Its small, lightweight, and ergonomic design allows for easy scanning in difficult-to-reach areas, a great alternative to automatic scanners in such situations.

When corrosion mapping of pipework lengths is the predominant inspection requirement, the STIX Corrosion XY scanner is the go-to scanner type, providing a 2-axis option for phased array corrosion mapping of pipework and vessels. The versatile solution is capable of hosting a range of Zero Degree PAUT methods such as; local immersion PAUT utilising the Aqualock V2, Dual-Linear Array & Linear array contact probes, ensuring users can maximise POD, coverage & data quality.

Having two encoded axis and an extremely low profile, the STIX Corrosion affords equipment users an efficient semi-automated scanner for corrosion mapping of large surface area assets.

Ask an ExpertBenefits

- Software enables assisted defect analysis while shared hardware components extend higher return on investment.

This turnkey inspection solution maximizes coverage, improves dexterity, and reduces dead zones. By sharing components, this is the most cost effective and complete corrosion mapping package available on the market today.

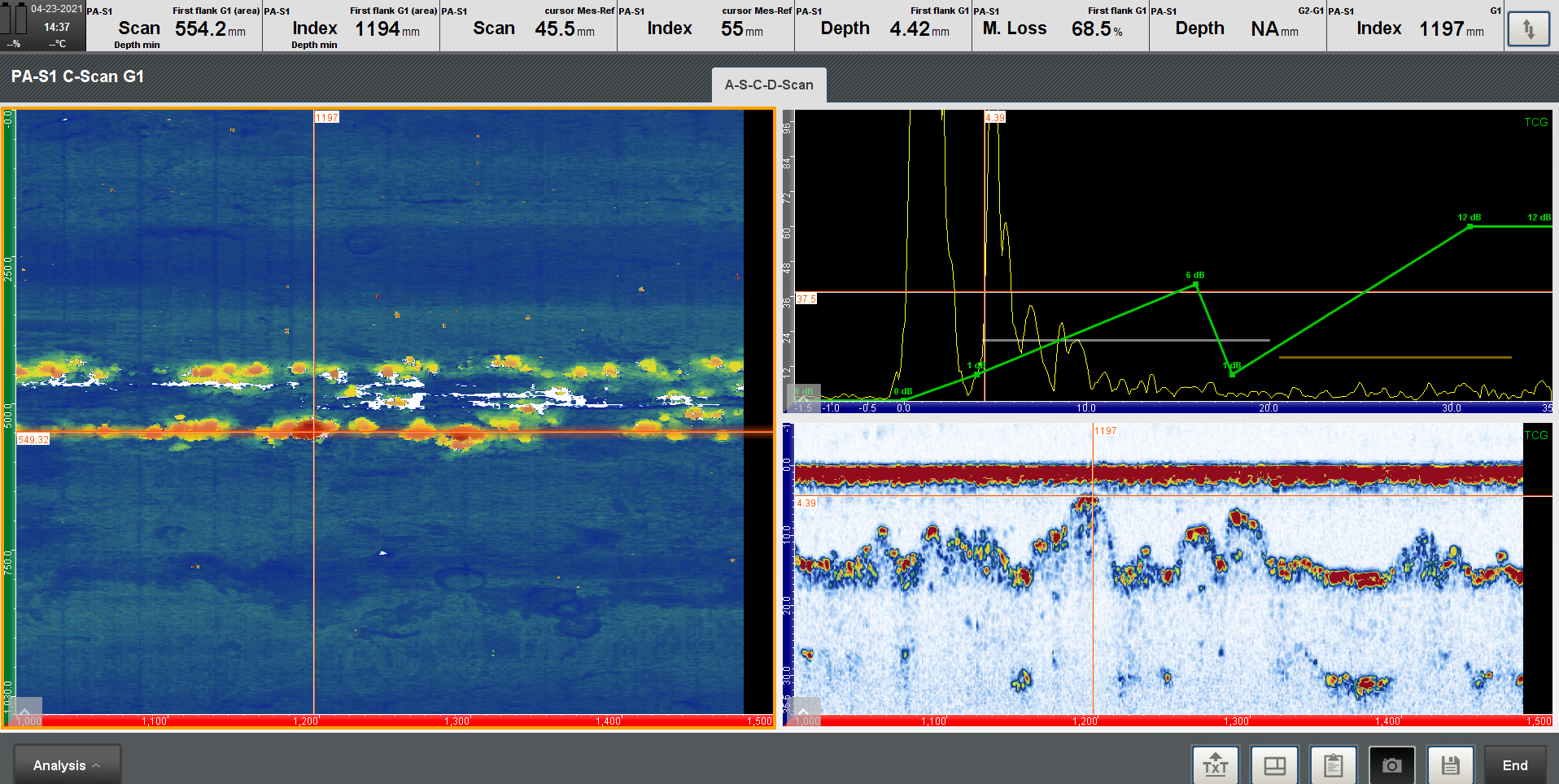

All of these ergonomic and cost efficiency improvements are a great compliment to Capture™ and Cypher® acquisition and analysis software embedded on the Mantis™ and Cypher portable phased array ultrasonic testing instruments. Operators have assisted defect analysis tools to instantly locate areas of wall loss, automate remaining thickness measurements, minimize re-analysis through utilization of floating gates, and provide a 3D map of the areas that have been scanned.

Breaking new ground in inspection technology, the Cypher Instrument and automated crawler solution deliver unprecedented productivity gains through smart, integrated piloting software — all in a user-friendly package that requires minimal scanner familiarity, opening the door to a broader range of users.

Eddyfi Technologies presents a unique, symbiotic product offering that leverages advanced technologies to provide the inspection solutions that are trusted to deliver all the data necessary for proactive asset health management programs. Contact us to discuss optimizing your operations today.