Assessing Flow-Accelerated Corrosion with Pulsed Eddy Current

A high-temperature, high-velocity fluid races toward a 90° bend in an insulated carbon steel pipe. The outcome is inevitable: Flow-Accelerated Corrosion (FAC) at the elbow’s extrados on the inner surface of the pipe.

The Challenge

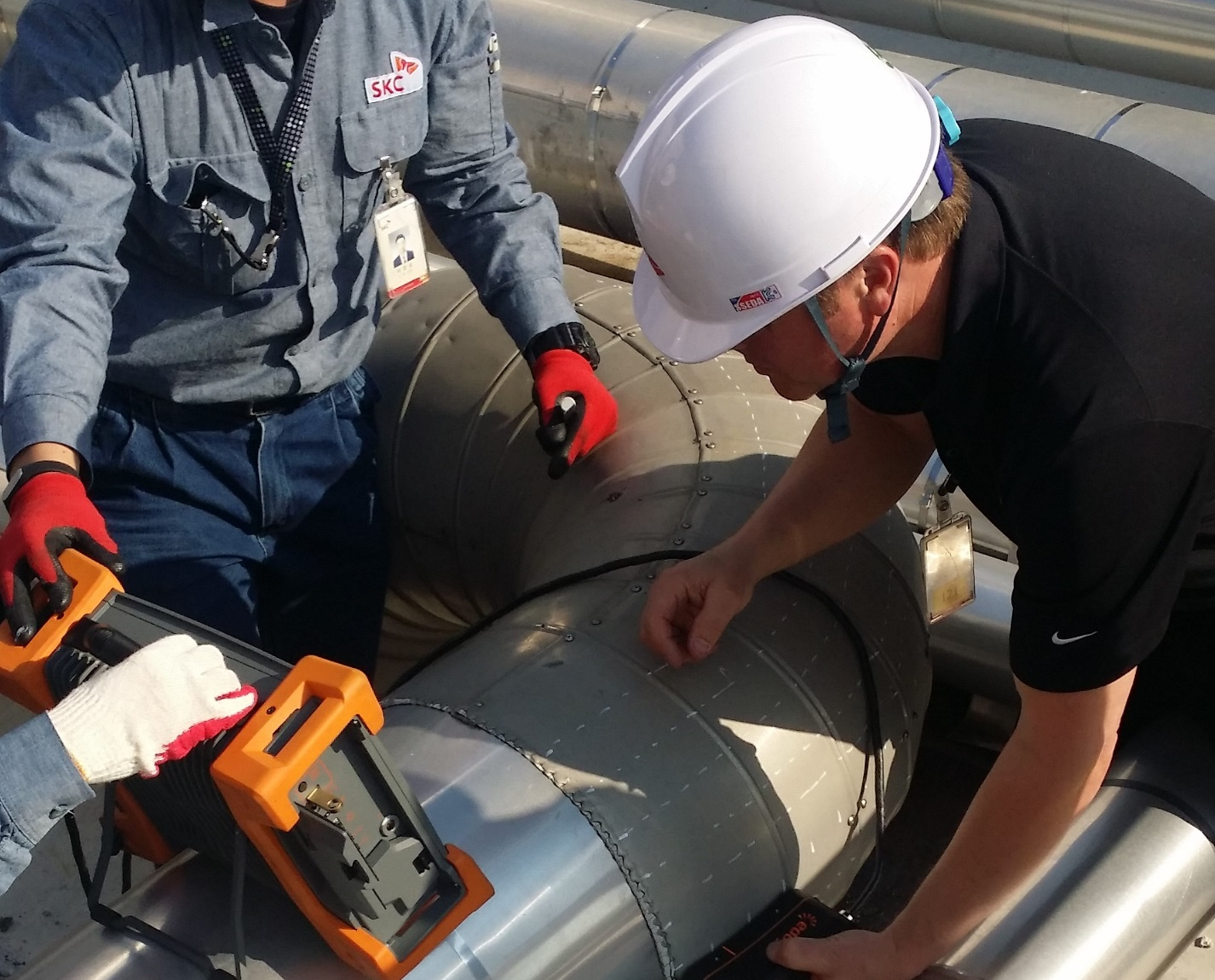

In-service inspection of a carbon steel pipe elbow over more than 50 mm (2 in) of insulation and an aluminum cladding without removing the insulation.

A major petrochemical refining company in Asia challenged Eddyfi Technologies to come up with an inspection solution capable of detecting FAC and erosion in carbon steel pipes and elbows containing high-temperature fluids travelling at high-velocity.

Flow-accelerated corrosion is a corrosion mechanism where a normally protective oxide layer on a metal surface dissolves in fast-flowing fluid. The underlying metal corrodes to recreate the oxide, perpetuating metal loss. By definition, the rate of FAC depends on the flow velocity. FAC often affects carbon steel piping.

Piping specifications are:

- Diameter: 318.5 mm (12.5 in)

- Wall thickness: 9.5 mm (3/8 in)

- Insulation thickness: 60 mm (2.4 in)

- Weather jacket: aluminum, 0.5 mm (0.020 in) thick

The inspection must be performed in service. The insulation and aluminum cladding must remain intact. A further challenge arose from the articulated, design elbows and straps.

Two test areas were identified: a straight section of insulated piping where no damage was anticipated, and an elbow along the same pipe where no FAC was anticipated, but it was possible to hear the fluid rushing past as it accelerated through the elbow.

The Solution

Advanced PEC solution capable of detecting FAC and CUI without removing insulation or cladding while system is in service.

The Lyft® pulsed eddy current solution was specifically designed for this sort of application. At a wall thickness of 9.5 mm (3/8 in) and total liftoff 50.8–63.5 mm (2.0–2.5 in), this application comfortably fits within the operating range of the medium PEC probe (PEC-089).

The pipe’s OD circumference is roughly 1.0 m (39 in). This application’s damage mechanism areas were anticipated to be a good fit for the ~100 mm (3.9 in) footprint of the PEC-089 probe.

Lyft is as capable of detecting and assessing general corrosion on the outer surface of the pipe as it is of detecting FAC on the inner surface, even through an aluminum sheathing and more than 50 mm (2 in) of insulation.

The first pipe area to test was a straight section of pipe well away from any elbows, valves, or junctions.

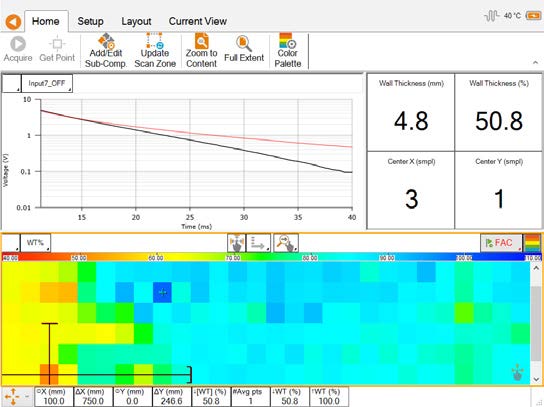

Using the built-in encoder of the probe, the straight section was scanned with the Lyft dynamic scan mode. This mode allows scanning continuously, under perfect circumstances at 75 mm/s (3 in/s). Additional material thickness and liftoff may reduce the maximum speed—in this case, the maximum speed was 50 mm/s (2 in/s) with a scan resolution of 11.9 mm per sample (2.1 samples per inch). A quick review of the scan data showed no significant wall loss.

The second target area was the outermost curved surface (extrados) of an elbow, upstream from the first area. It was possible to hear the fluid as it accelerated around the bend in the elbow. The structure of the aluminum weather jacket elbow precluded the possibility of using the dynamic scan mode (the irregular surface and sudden step changes did not allow the encoder to operate properly). A 50 × 50 mm (2 × 2 in) grid was mapped out on the surface of the elbow so that the scan area was the elbow’s extrados (where FAC was most likely to occur).

In grid mode, the probe is moved from one grid location to the next as the operator presses a button built into the probe to record each scan position. Although offering a slightly lower resolution, the grid scan allows rapidly scanning large areas and can accommodate all irregular surfaces.

Inspection results indicated substantial wall loss concentrated at the bend transition and continuing through the extrados of the elbow, the extent of which was not anticipated.

Benefits

- Detecting previously undetected FAC at elbow extrados on the inner surface of in-service pipe without removing insulation or cladding.

Lyft demonstrated that it could detect and assess FAC damage on the ID of the pipe, through more than 50 mm (2 in) of insulation and an aluminum cladding without this tube being taken out of service.

Right balance between wall thickness and liftoff

The Lyft system (instrument, probes, software) can accommodate material thicknesses 3.1–38.0 mm (0.125–1.500 in) and insulation thicknesses up to 152 mm (6 in) with or with aluminum, galvanized, or stainless steel jacketing.

Removes the need to strip cladding and insulation to perform inspection

Unlike ultrasonic thickness testing and visual inspection, PEC can scan over the weather jacket and insulation over the component under test, lowering costs and inspection times.

Quick inspection

With gridmapping and dynamic scan modes.

Intuitive imaging

C-scans allow quickly and easily detecting defects.

Detailed automatic reports

Lyft automatically generates editable reports for easy sharing and archiving containing detailed information about the inspection.

Durability

The Lyft solution is rugged and portable, it is made for harsh environments, and can operate on surfaces up to 120°C (248°F) (with probe shoe).