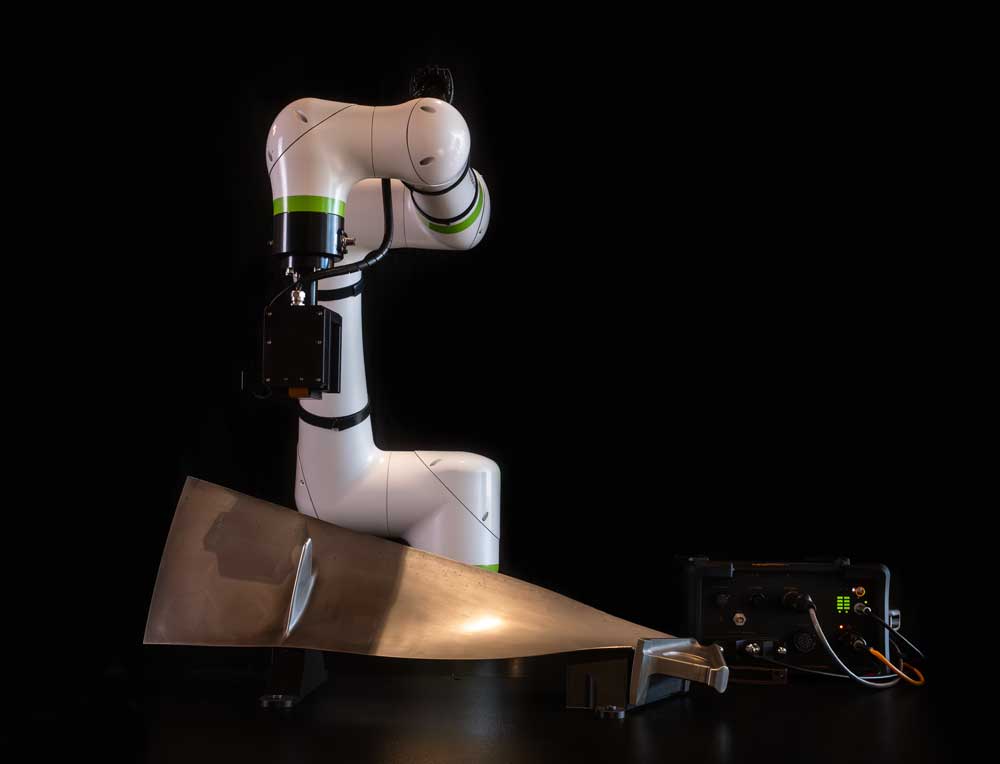

Our Robotic Solution brings unmatched speed, precision, and reproducibility to complex inspections. By combining custom Eddyfi probes with the trusted Ectane® 3 or Panther™ 2 instrument, gain production‑grade, repeatable scans—even on the most intricate geometries. Say goodbye to fatigue, inconsistency, and slow cycles: expert‑level results are now available at the push of a button.

Talk to an Expert Request a DemoDetails

Your Expert Inspector, Automated

This integrated robotized solution with ECA / PAUT is equipped with a custom Eddyfi probe at the end effector, all controlled by Ectane 3 or Panther 2. Unlike single‑coil, mono‑element systems, our 32‑element array covers more surface area per pass, dramatically accelerating inspections. The robot executes programmed motions with perfect consistency, eliminating the variability and fatigue that affect human inspectors.

Note: robot envelope shown for illustration (customizable on request)

Why it matters

Humans are exceptional but tire over long shifts and require years to master complex, repeatable motions. The robot never fatigues, reproduces the programmed gesture precisely, and maintains peak performance across high-volume production. Beyond simply matching human expertise, it pushes past natural limits—executing motions with consistency, speed, and accuracy no human can sustain. The result is an inspection process that not only mirrors expert skill but continuously outperforms it in every cycle. Unlock the Power of Automated Precision

Independence — Program the robot once and let any trained operator achieve expert‑quality results, shift after shift.

Precision — Reach the accuracy of a Level III inspector with decades of experience—without human fatigue.

Repeatability — The robot reproduces the exact path, pressure, and speed endlessly, ensuring stable, auditable outcomes.

With up to 32× faster inspections compared to manual techniques, this solution gives the power to deliver consistent, high-quality inspections at an industrial scale. By combining Eddyfi’s advanced technologies with the flawless precision of robotic motion, it eliminates uncertainty—ensuring that every flaw, from cracks to thinning, is detected with unmatched confidence and clarity.

Industries That Demand Perfection

The aerospace and aeronautics sectors rely on this advanced NDT array technologies to detect sub-millimeter flaws in mission-critical components—where safety is non-negotiable and failure is simply not an option.Beyond aerospace, opportunities are emerging in automotive manufacturing, assembly lines, and nuclear applications, where high‑volume, repeatable inspections are equally vital.

The Eddyfi Difference

Our robotic ET Array solution stands apart thanks to:

Speed & Coverage — Broad array coverage reduces cycle times dramatically.

Consistency at Scale — Identical results run after run, no matter the operator.

Expert‑Level Results at One Button — Non‑experts can achieve Level III quality instantly.

Beyond Cracks — Detect thinning, wall erosion, and more for comprehensive data insights.

Built for Aerospace

There are many industries and applications where precision is non-negotiable. Aerospace is one of those. Our integrated robotized solution is purpose‑built for the most demanding inspection scenarios. It excels at scanning complex airframe geometries where manual consistency simply cannot be achieved, and it delivers reliable results on engine components and thin skins that require the detection of sub‑millimeter flaws. For high‑volume production lines, it ensures traceability and repeatability, making it an invaluable tool for manufacturers who cannot compromise on quality.

From Single Coil to Full Array Power

Traditional mono‑element probes use a single coil, making them slow, inconsistent, and requiring multiple passes.

In contrast, the Eddyfi array probes leverages 32 elements, achieving broader coverage per pass, faster cycle times, and consistent expert‑level results.

Bring Expert‑Level Inspection to Your Line

Talk to an Expert Request a DemoThree Steps to Confidence

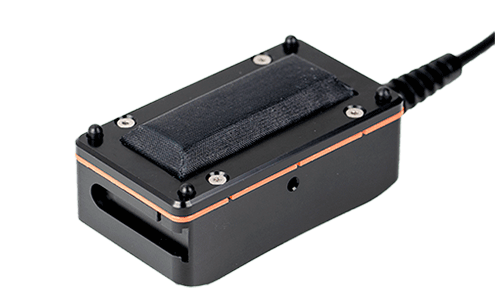

CustomProbe — Designed specifically for your geometry and defect profile.

Robot‑Arm Integration —Eddyfi Technologies’ cutting-edge probes and NDT solutions integrate seamlessly with any major robot brand. By choosing a robot-agnostic approach, we give you the freedom to combine the best of both worlds—our world-class inspection technology with your robotic platform of choice. The result: a tailor-made solution that maximizes performance without compromise.

Industrial compact solution-driven Acquisition — Ensures synchronous multi‑element excitation and dependable signal quality.

Proof You Can Trust

Our solution generates structured, repeatable datasets that allow you to:

· Maintain consistent inspection records

· Simplify quality control and audits

· Compare results batch after batch with confidence

Engineered with industrial safety in mind, each deployment includes site‑specific validation, guarding, and compliance considerations. You get peace of mind alongside powerful performance.

- {{item.moduleNameDisplay}}

- No results found

- View more results

-

{{group.moduleNameDisplay}}

- No results found