Eddyfi’s Spyne New Screening Tool: Leave No Crack Behind!

From: Friday, March 22, 2019

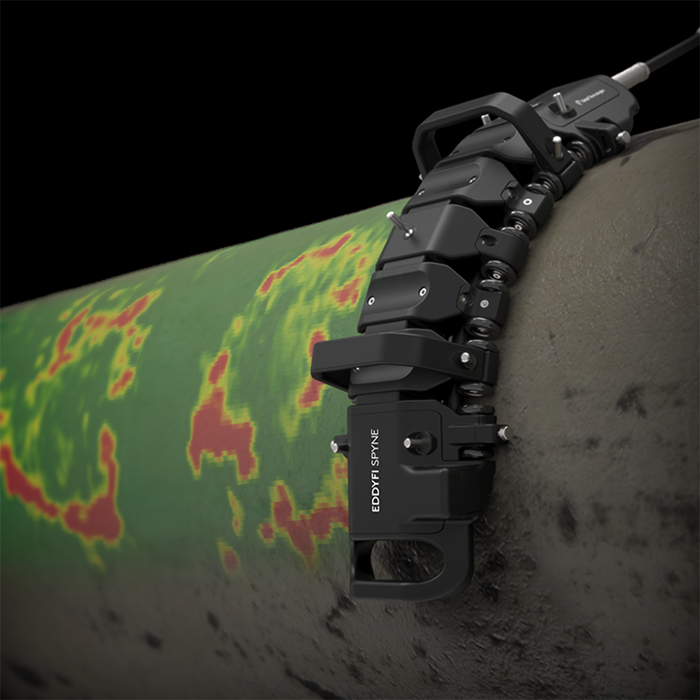

Québec, Canada, March 22nd, 2019 — As a one-of-a-kind product, this Eddyfi’s ECA adaptable screening tool is specifically designed to maximize the detection of all types of crack, such as Stress-Corrosion Cracking (SCC), fatigue and chloride cracks, subsurface indications and many others, on pipelines, pipes, vessels or tanks. It combines speed, PoD and efficiency in one solution for unparalleled effectiveness!

Eddyfi is thrilled to introduce Spyne, an ECA probe engineered to meet the more precise needs of the NDT exponential expanding market. With a particularly high Probability of Detection (PoD), its impressive speed and adaptive capabilities for a wide range of applications, Spyne is revolutionizing the work of technicians in the field and above all, ensures control of the human factor like never before.

Michael Sirois, Technological Director at Eddyfi Technologies, explains the importance of improving non-destructive inspection systems and one of the main applications targeted by the new solution: ‘’In North America, over the last 20 years, some 250 annual pipeline incidents have caused over $ 6.3 billion in property damage. More than 2.5 million barrels of hazardous liquids was spilled and just about half was recovered in cleanup efforts. Eddyfi Technologies has been known to be forward thinkers, and we applied this when developing this product. With the help of advanced NDT technology, we are bringing to the market a solution that controls the human factor and provides reliable and repeatable data. It is a game changer for NDT in various industries, such as oil & gas, something significantly improved when compared to the traditional methods of inspection.’’

With a scanning speed up to 600 mm/s (24 in/sec) and 200 mm (8 in) of coverage in a single pass, the operator can perform quicker inspections while ensuring optimal defect detection. With Spyne, data quality doesn’t depend anymore on quantity of surface being scanned, difficult position during inspection, bad surface preparation due to poor sandblast.

Or contrast, condensation on pipes, or other environmental factors which can affect conventional inspection methods. Another breakthrough is that it can inspect on hot surfaces, up to 150 degrees Celsius (302 degrees Fahrenheit), sometimes avoiding or reducing shutdowns thus saving time and money. The implementation of the Grid-As-U-Go™ feature also makes the testing even simpler and quicker, since it significantly minimizes the inspection preparation time. Spyne has also been designed with versatility in mind, a good example being the probe’s infinite inspection adjustments from 150 mm (6 in) OD pipes to flat surfaces. Not only is it adaptable from a mechanical standpoint, its spring-loaded, interchangeable, flexible ECA probe allows for different types of inspections with different types of probes, useful to suit ferritic and non-ferritic alloys. As for instruments, Spyne is fully compatible with Eddyfi’s Reddy® 128 or with Ectane®. Combined with the Magnifi® software, it provides powerful assisted detection capabilities and instant screening reports, making the overall inspection process faster and more efficient than ever. The ultrafast Spyne screening tool is the perfect mix of simplicity and technological edge for an unprecedented inspection effectiveness from operators to asset owners to inspection companies. For more about this groundbreaking solution, visit http://www.eddyfi.com/spyne.

Information Veronique Chayer Marketing Leader Eddyfi Technologies Tel.: 418-780-1565 ×430 Cell.: 581-999-9202 [email protected]