Inspection of Welds with Corrosion Resistant Alloy (CRA) Cladding

Ask an expertIn order to extend the service life of oil, gas and petrochemical components prone to corrosion, the use of Corrosion Resistant Alloy (CRA) cladding and/or weld overlays are now common practice, and pipelines transporting hot and corrosive materials are no exception. When it comes to inspecting these clad pipelines, inspectors must —among other things— pay attention to the dissimilar girth welds, including weld root integrity as a failure here equates to carbon steel being exposed to sour fluids and potentially catastrophic consequences.

The Challenge

Ultrasonic inspection of CRA-clad girth welds is a challenge due to their anisotropic nature, their high attenuation factor and the interference with the protective layer, making typical shear wave examinations unsuitable.

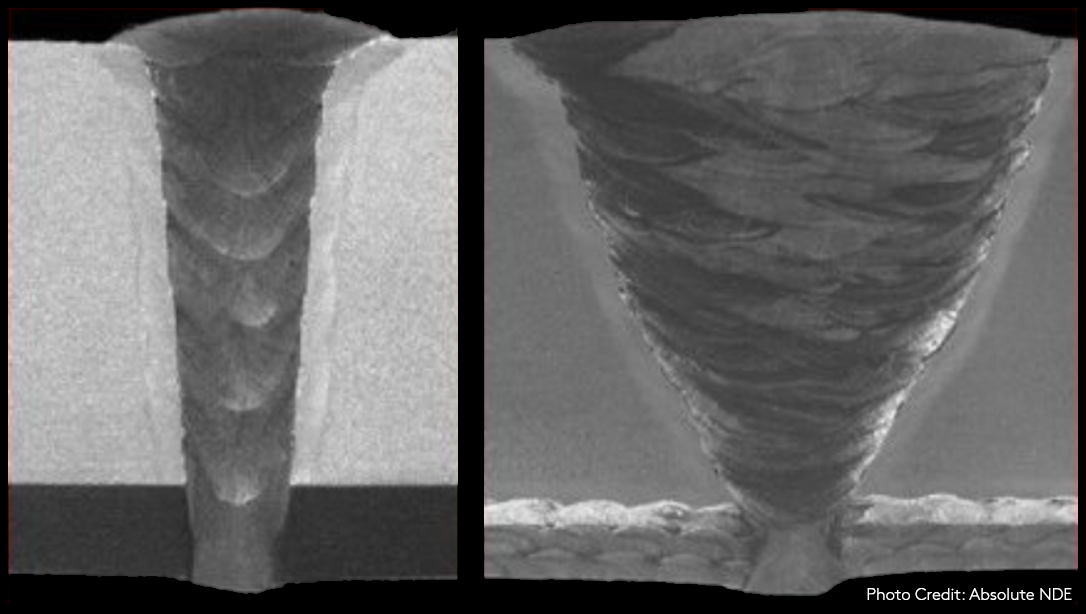

The protective layer designed to extend the useful remaining life of pipelines presents a challenge during ultrasonic testing (UT) of cladded pipes with dissimilar metal girth welds. CRA welds interfere with the shear wave transmission because of velocity and grain structure changes, creating mode conversion, refraction, and scattering amongst other adverse effects. Rather, inspection is performed using low frequency longitudinal waves, and is typically limited to half-skip mode (half-vee) – which requires removal of the cap for complete coverage of the weld root, volume, and upper area.

CRA-clad dissimilar material welds (Photo credit: Absolute NDE)

The Solution

Low-frequency dual linear and dual matrix array probes with large apertures controlled by a user-friendly and easy-to-setup phased array ultrasonic testing instrument capable of firing up to 64-element apertures simultaneously.

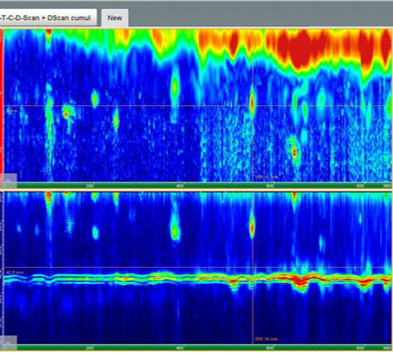

To overcome transmission through dissimilar materials, the use of Phased Array Ultrasonic Testing (PAUT) linear and matrix probes in Transmit-Receive Longitudinal (TRL) mode is recommended by the industry. These probes are known as dual linear and dual matrix arrays (DLA and DMA). In the TRL technique - sometimes called pitch-catch technique - the transmitter and receiver transducers are unique to each other so that collected signals originate only from the area where the two beams intersect. Using a separate pulser and receiver, the wedge size is reduced, and the probe can operate closer to the weld for increased sensitivity with no dead zone or internal wedge echoes. This allows inspectors to determine whether there is Lack of Fusion (LOF) at the weld bevel, for example. Using the TRL technique with a large aperture and precise steering enables better Signal-to-Noise Ratio (SNR) and Probability of Detection (PoD) in thick CRA welds. The use of matrix arrays allows creation of multiple beam skew angles and focal positions to optimize detection and coverage. In terms of equipment, this translates into 64+ parallel architecture systems driving probes with 64+ elements.

For example, the High performance Cypher®64:128 system, come with a standard DMA/DLA interface for easy programming of the setup directly in the flaw detector.

The proposed solution includes:

Cypher(or Panther™) units to operate with high channel count dual probes for high resolution sector scanning and TFM, plus automatic time corrected gain (TCG);

Embedded software with live configuration offered through the intuitive operating systems;

1-axis chain scanner for data encoding and defect positioning;

Linear, DLA and DMA probes and wedges kit.

Benefits

Efficient, full volumetric inspection of CRA-clad girth welds with adequate Signal-to-Noise Ratio and reduced stress for the technician thanks to an intuitive and powerful phased array ultrasonic testing flaw detector.

Thanks to advanced PAUT, reliable CRA weld inspection is not only feasible, it is optimized using intuitive software and configuration tools. With easy onboard setup of dual probes and natively implemented PAUT, TFM and hybrid methods on both Cypher and Panther instruments, operators can easily adjust ultrasound settings for the best data collection results powered by high channel count phased array probes. Finally, Eddyfi Technologies’ advanced PAUT flaw detectors are compatible with all dual probe manufacturers and typical scanners on the market.