Fueling Safer Tank Inspections with Innovative Robotic Solution

Ask an expertAs asset owners increasingly prioritize the health and safety of employees alongside the environment, industry is witnessing leaders begin to challenge currently accepted inspection techniques that place workers in potentially dangerous environments. One example of this is buried fuel tank inspection. According to one source, there are over 126,000 retail fuel outlets in the United States of America alone. Each of these facilities have an average of three to five tanks beneath each station, or more than 500,000 buried fuel tanks. Currently, the only legally recognized inspection approach for these mandatory autogas tank assessments requires human entry into the confined space. Providing levels of protection for inspectors far exceeding legal requirements, Shell is now engaging the Bulgarian Oil and Gas Association as well as other relevant institutions to propose the acceptance of an alternative that allows operators to continue to put the safety of people and the protection of the environment at the forefront of operations.

The Challenge

Identify an inspection solution that can provide a complete assessment while keeping the human outside of the buried fuel tank.

In Bulgaria, fuel dealers are required to conduct a complete inspection of autogas tanks every four years. Human entry into the tanks is the only legally recognized inspection practice. The process involves inspectors of the State Agency for Metrological and Technical Supervision to enter into the confined space. Shell provides its workers with protective wear to perform this dangerous work and assigns a person to stand outside the tank during inspection, maintaining continuous radio contact. Confined space entry poses a number of risks to even the most well-prepared personnel. This includes gassing, in which fatality is a very serious possibility. Therefore, Shell has sought an alternative solution for the inspection of pressure vessels like underground fuel tanks which negates the entry of people inside the vessel.

The Solution

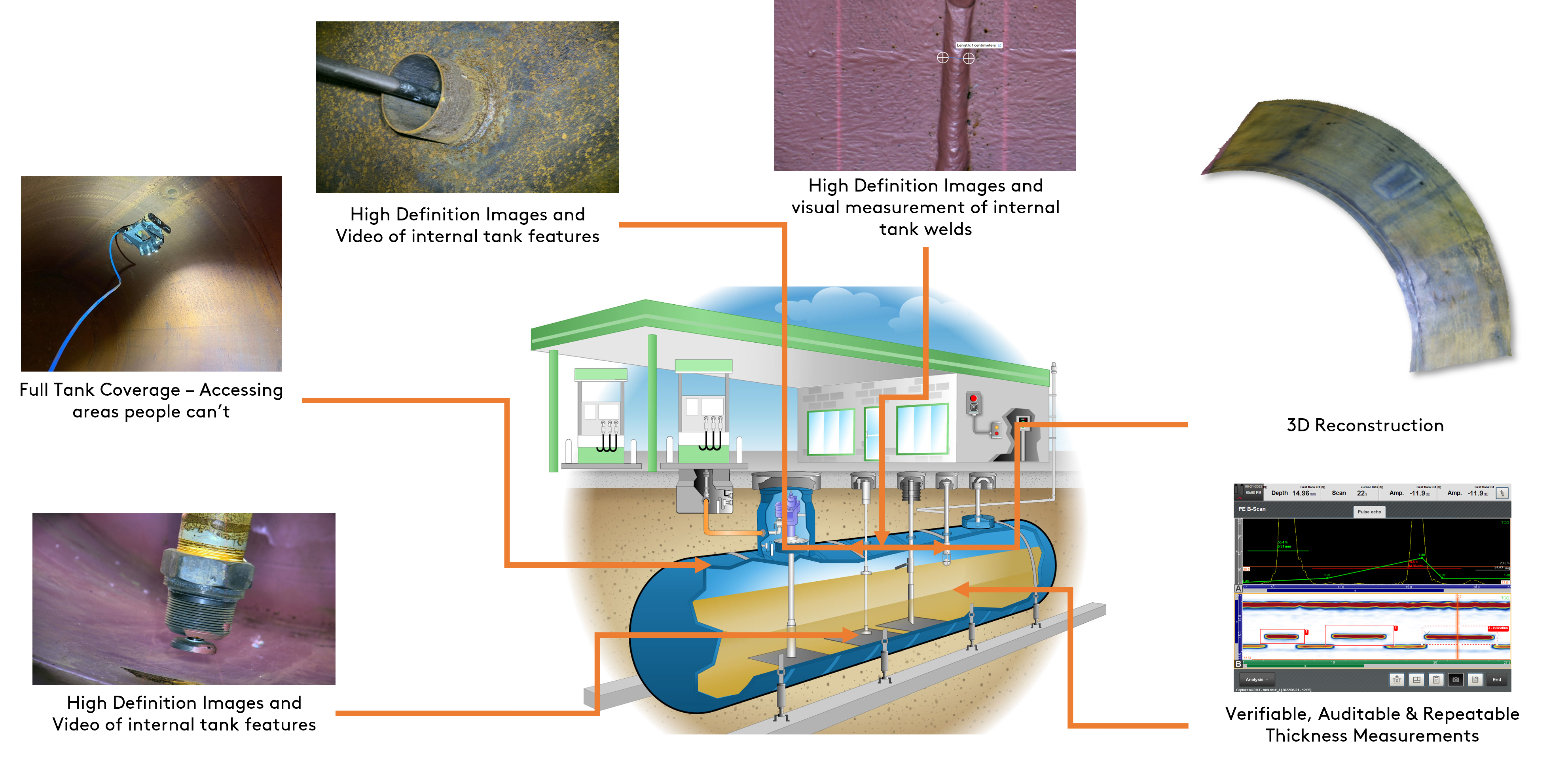

A non-destructive testing enabled robotic platform allows remote internal inspection within confined spaces.

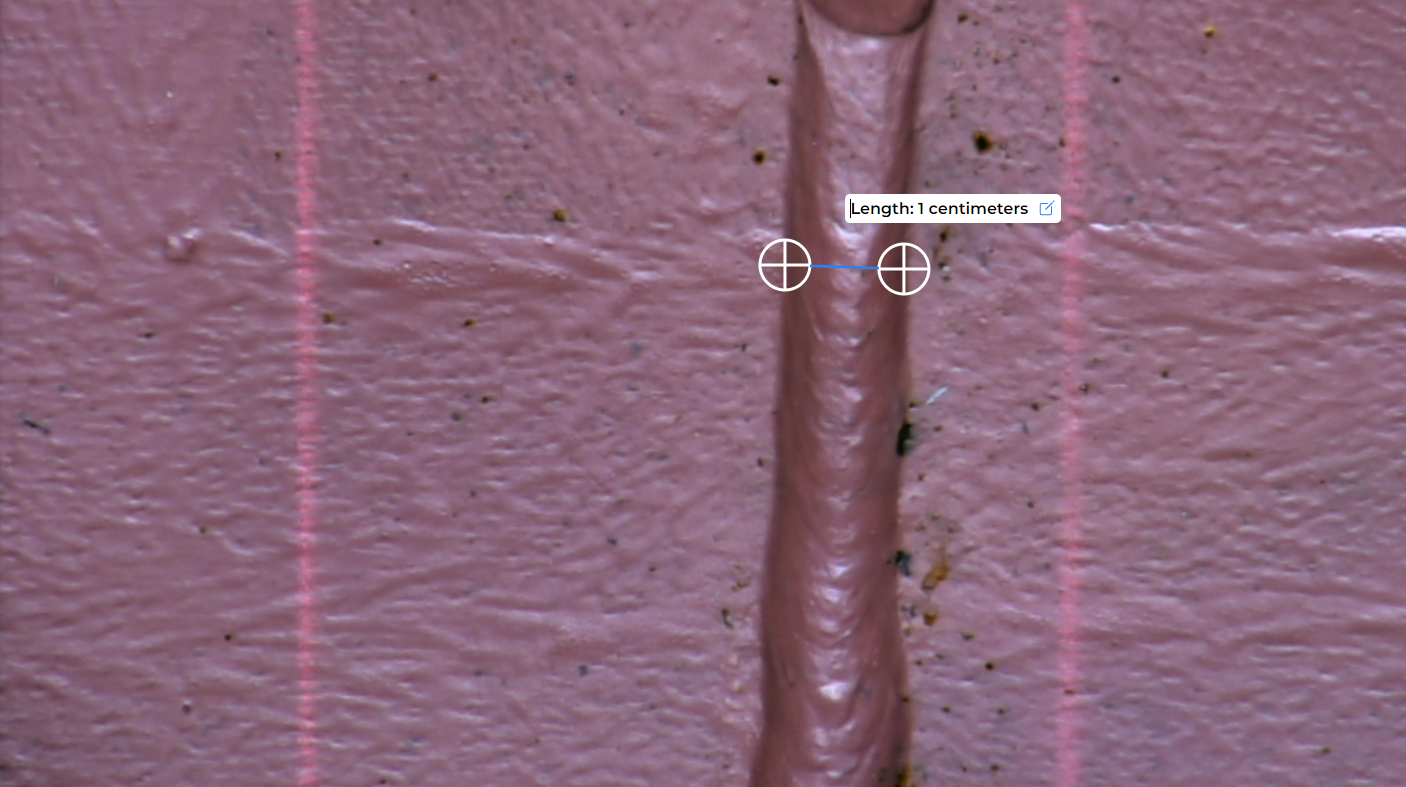

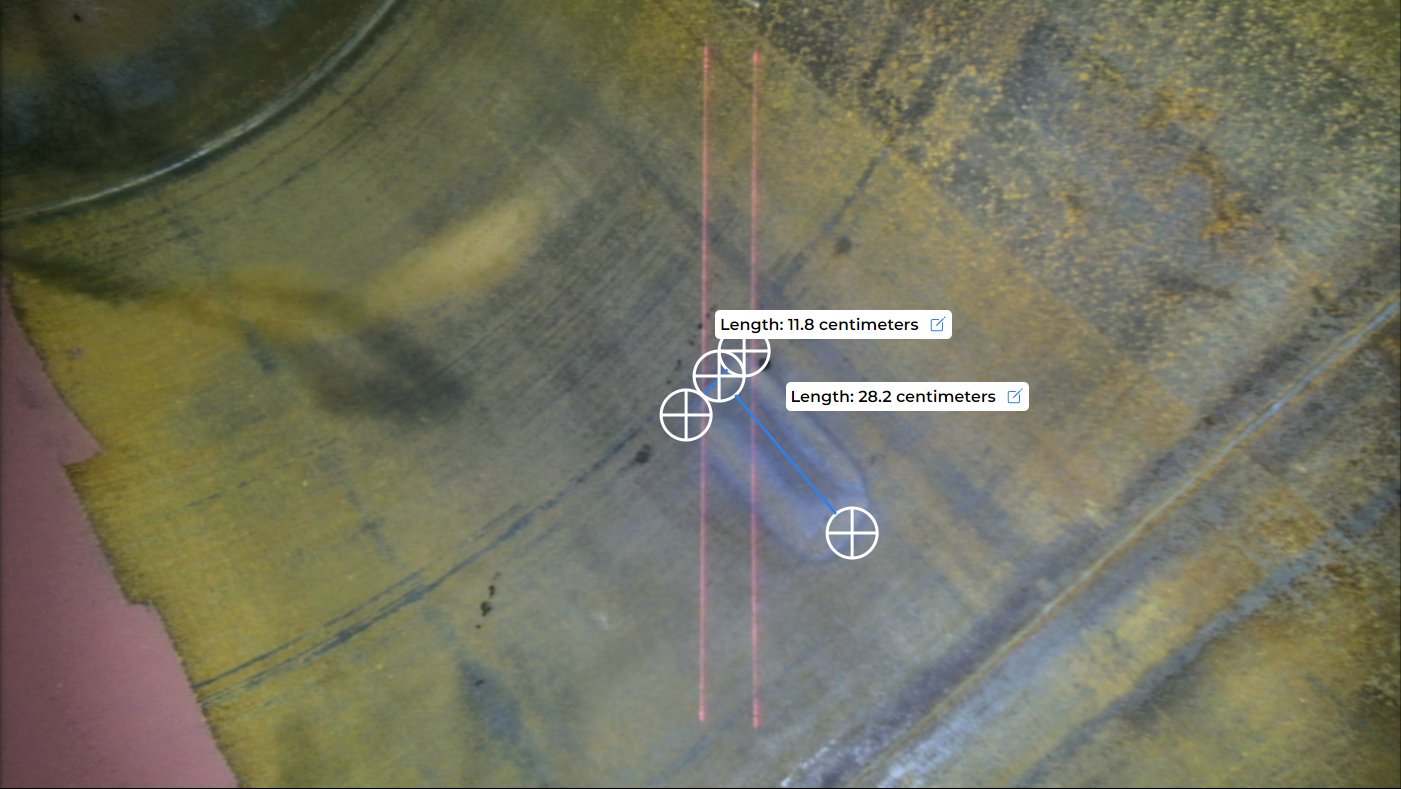

Laser lines for obtaining measurements

>

>

Estimation of area with scalar measurement

When Shell approached Eddyfi Technologies for a safer solution for underground tank inspection, the scope required that the system provide an equal or better examination to manned assessment of the following:

- Coatings and the basic metal of the inner surface for damage caused by corrosion or erosion, cracks, bumps, pitting, etc.

- Tank wall, bottom, sides, reinforcement rings, welds, and internal structures such as drop tubes

- Characterization of flaws detected including dimension, extent, depth of error

- Opportunistic tank wall thickness testing.

The VersaTrax™ M-Series (formerly known as Magg™ 310) enabled non-destructive testing inspection robot provides the same or better results as manned inspection of buried fuel tanks, while increasing the safety for the inspector. The inspection crawler does not replace the inspector but is a tool that extends the inspector’s capabilities and keeps him or her outside of the tank in the safe zone. It is designed to increase inspection efficiency and increase safety. The proven technology was successfully deployed at a Shell site; a safer setup and inspection solution with no manned entry was demonstrated.

The robotic crawler has the capacity to travel 360 degrees around the tank. It provides superior remote visual inspection, allowing for greater detail from more complex orientations. The onboard camera and robot move simultaneously allowing for high-speed weld scanning. Integrated laser lines offer scalar/reference measurement points that not only provide a great path to follow for driving along welded joints, but also project a calibrated laser distance of 70 millimeters (2.8 inches). Operators can use software to obtain measurements knowing this fixed value.

Scalar measurement is usually limited for measurement on flat surfaces while perpendicular; however, freely available software allows for straightening of these surfaces based on the constant projection of parallel lines from the laser emitter. This allows for estimation of area.

The inspection robot has a higher quality capacity for thickness measurement of the tank wall and associated coatings. Variations of the system deployed include single crystal tank thickness testing and phased array ultrasonic testing. This volumetric tank thickness testing delivers a quantifiable approach with measurement data saved for future reference and condition monitoring.

See pricingBenefits

- Beyond improved safety and environmental performance, the robotic solution provides more enhanced inspection data and comprehensive reports.

With higher quality data comes higher quality inspection reports. Tank photogrammetry turns flat images into a fully manipulable 3D model that is exported as an OBJ file compatible with most 3D software. It is topographically rendered. It can also be exported as a CAD file combining ultrasonic testing/laser scanner data. This digital twin is useful as an ideal baseline for other purposes including monitoring for quality assurance.

The industry standard inspection solution features automatic report export functionality directly from the ultrasonic testing instrument. When integrated with other technologies including alternating current field measurement, eddy current array, and remote visual inspection, free-type ability is also available. The standardized output is CSV for data with reporting in Microsoft Excel and PDF formats. The permanent record of inspection provides a more efficient approach to underground fuel tank assessments, leveraging repeatable non-destructive testing data that provides comparative year-over-year condition monitoring.

Shell supports a legislative change at the government level in countries where there is a mandate for manned inspection to switch to robotic inspection. This technology acceptance paves the way for increasingly complex tasks including operating in tanks with obstacles such as ribbed tanks as well as remote tooling for unmanned repairs. To learn more about robotic inspection and how it can improve your operations, check out the Eddyfi Academy.

Contact our team of experts for more information or visit the online eStore to build your custom quote.