Confined Space Ductwork Cleaning with Custom Robotic Crawler

Ask an expertPreventing the spread of airborne illnesses has never been more critical. It is evident in the masses wearing personal protective equipment under the current extraordinary circumstances where a global deficit for these supplies continues. A key component impacting air quality involves heating, ventilation, and air conditioning ductwork in both commercial spaces and home environments. From the kitchen ducts found in food court kitchens to the air conditioning systems in shopping malls, high rise apartments, and office buildings, a proper maintenance program will plan for regular cleaning of this intricate ductwork to ensure optimal system performance and potential pollutant source removal.

The Challenge

Effectively clean various ductwork systems like food court kitchen and air conditioning ducts

Like any other system, ducting used for heating, ventilation, and air conditioning requires an effective maintenance and repair program for peak performance. Cleaning is an important element of the process, and the diverse range of channels and varying geometry present challenges with regards to access and maneuverability. These systems may feature circular or rectangular ducts as small as 200 millimeters (8 inches) potentially placed in high ceilings with difficult-to-reach and/or limited entry points, spanning over long lengths. With these limitations in mind, it is also essential to consider that a solution made available must be able to validate the cleaning activity performed with an objective, auditable record.

Learn moreThe Solution

Custom robotic solution remotely cleans otherwise inaccessible rectangular and circular ducts

Rectangular Ductwork Robotic Crawler Orientation

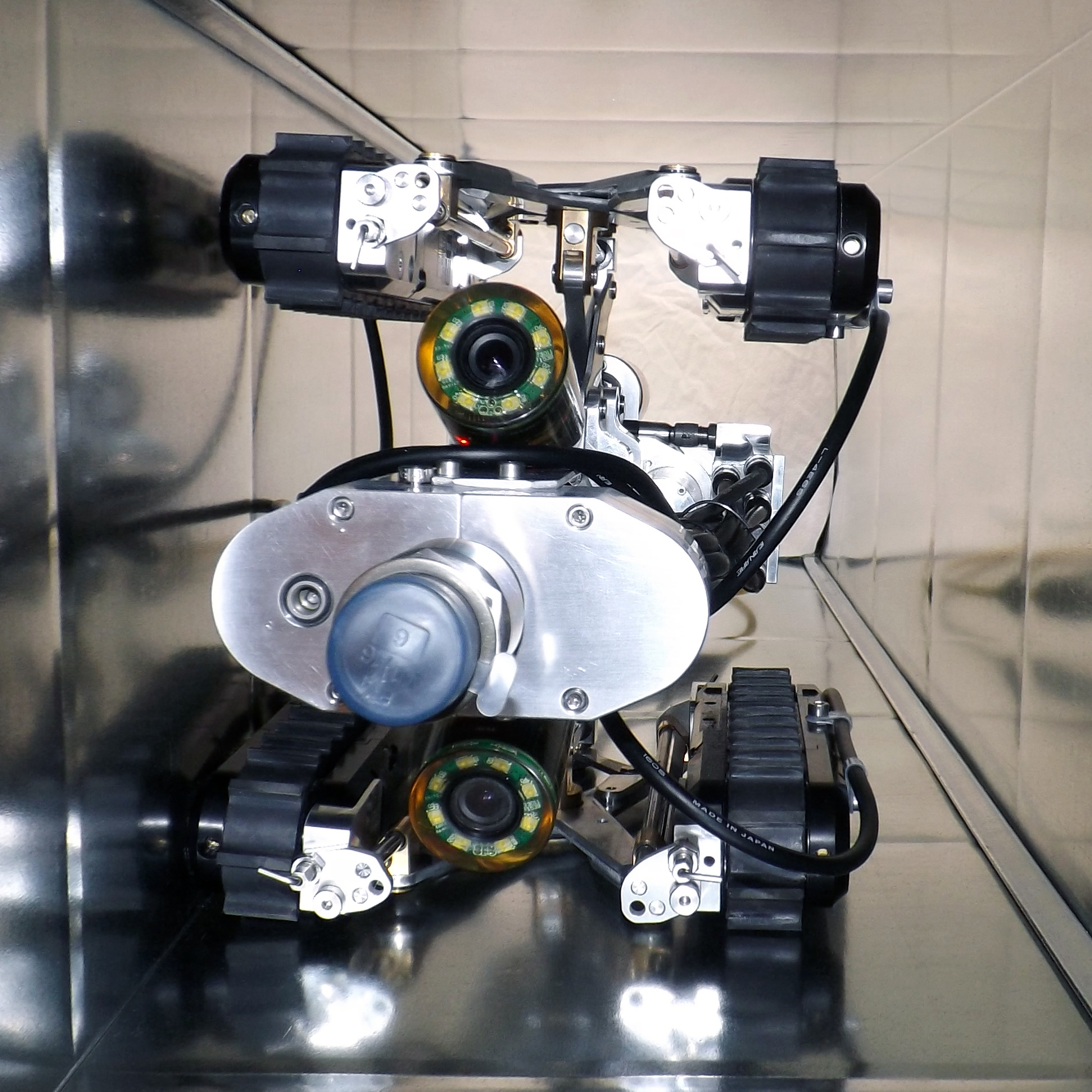

Circular Ductwork Robotic Crawler Orientation

The use of industrial robotics continues to expand with the high priority for public safety, and the future of robotics will increasingly see remote sanitization activities. A robotic crawler that is built on a multi-mission modular approach offers the adaptability required to overcome access and maneuverability obstacles encountered with confined space entry and varying diameter ductwork featuring multiple bends and elbows typical of heating, ventilation, and air conditioning systems. The custom duct cleaning robotic system presented here leverages a robust crawler track setup enabling cleaning in rectangular and circular ducts from 200 to 350 millimeters (8 to 14 inches) in diameter, up to 30 meters (100 feet) long. The cleaning robot can fit through a 190-millimeter (7.5-inch) opening for positioning. The flexible crawler is controlled through proprietary software driven with familiar Xbox controller operations. Onboard inspection cameras enable smooth navigation and post-work validation of satisfactory cleanliness levels as required.

The integrated cleaning system delivers high pressure dry ice through a rotating nozzle that can operate at variable speeds. The third-party technology was initially developed by the US Airforce as a method of rapid paint stripping from aircraft without damaging the underlying metal. Dry ice blasting uses dry ice micro pellets accelerated to high velocity. The combination of kinetic energy and the nano-level thermal shock effectively abrades surfaces without leaving water or abrasion residue, damaging active electrical or mechanical parts, nor creating any fire hazards.

Tradeshow Demonstration of OnSpec Robotic Solution for Remote Cleaning with Dry Ice System

Contact usBeyond Inspection

We create technology that enables people to perform tasks that they could not otherwise do, in places they could not otherwise go. OnSpec Robotics enable access to areas that are too dangerous or remote for direct human intervention, providing time and cost efficient operations. Learn more

Benefits

- Risk of airborne diseases such as Legionnaires mitigated with routine remote cleaning program

Originally designed to address remote ductwork cleaning operations in Singapore’s kitchen food courts and shopping malls as well as air conditioning systems in highly trafficked commercial spaces, this custom robot has attracted the attention of leading property and high-rise building owners who see the system as an effective response to ‘sick building syndrome’ and mitigating risks of airborne diseases such as Legionnaires. The difficulty of cleaning aircon duct systems has previously led to insufficient intervals of maintenance, and this easy-to-deploy robotic system has offered a welcome solution that supports the health and wellbeing of residents.

Where can Eddyfi Technologies robotic solutions for industrial applications help solve your challenge? Contact our team of experts to discuss your options today.