With more than a thousand units in the field, the Ectane® has empowered advanced electromagnetic inspections around the world for more than a decade. The third-generation unit is IP65 certified and supports a tenth technology, Remote-Field Array (RFA) for advanced tubing.

Details

Applications

- Shell and tube heat exchangers

- Condensers, Feedwater heaters, and boilers

- Fin-fanTM air coolers

- Chillers, air conditioning / HVAC

- Engines and turbines surface inspections

- ECA weld inspections

- Custom ECA probes for complex geometries

- Robotized and automated inspection systems

Unrivalled power and flexibility

Ectane is the reference when it comes to advanced electromagnetic tubing and surface inspections. Offering a broad 5 Hz to 10 MHz frequency range, eight channel inputs, and up to 32 timeslots, the instrument can tackle a broad spectrum of applications.

Modular by design, the 11 models of Ectane 3 are upgradable and can be retrofitted to meet your inspection needs. The unit is available in three different array configurations: 64, 128, or 256 elements with support for 10 technologies.

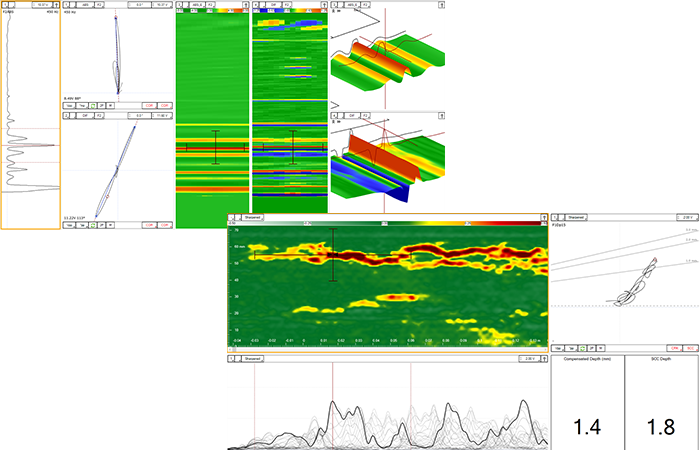

RFA, the latest advanced technology

Using a patent pending low-frequency multiplexer, Ectane 3 exclusively supports Remote-Field Array (RFA) technology. This probe family is the latest addition to the multi-technologies test instrument and brings high-resolution C-scan imaging to carbon steel tubing heat exchanger inspections.

RFA gives the analysts a greater insight on the defect morphology, and it's increased sensitivity allows the detection of defects closer to external features, which are normally missed by conventional RFT.

Learn more

IP65 certified

With a complete overhaul of the assembly, the Ectane 3 incorporates the latest electronic components available on the market in a more rugged platform than ever before. Building on the foundation laid by its predecessor for more than a decade, the IP65-certified Ectane 3 is the device you can count on to withstand even the harshest field environments.

Technologies

Ectane 3 enables the highest quality inspections by allowing a wide range of technology combinations whether it be:

- Eddy Current Testing (ECT)

- Eddy Current Array (ECA)

- Tangential Eddy Current Array (TECA™)

- Remote-Field Testing (RFT)

- Remote-Field Array (RFA)

- Near-Field Testing (NFT)

- Near-Field Array (NFA)

- Magnetic Flux Leakage (MFL)

- Magnetic Flux Leakage Array (MFLA)

- Internal Rotating Inspection System (IRIS) ultrasonic testing

Want to see Ectane 3 in action? Book a demo!

SmartMUX™

SmartMUX is the Ectane’s integrated and programmable ECA multiplexer. It offers the freedom to use absolute, differential, or transmit-receive eddy current coil topologies. More elements means better coverage, higher resolution, uniform sensitivity, and faster inspections. The Ectane 3 can support probe designs with up to 256 channels.

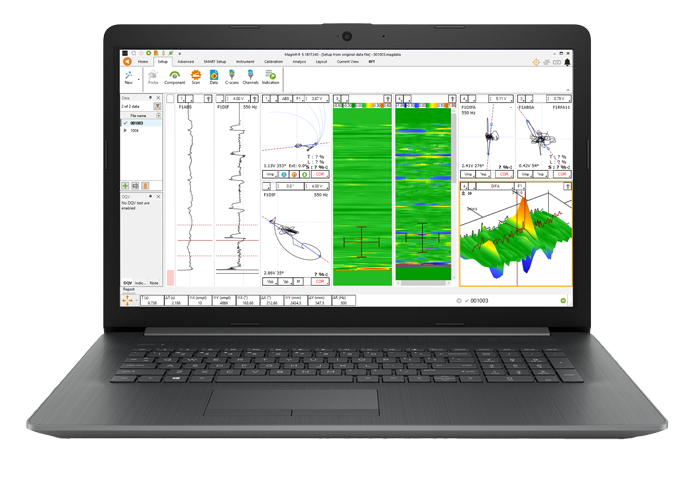

Magnifi® software

Magnifi is the cutting-edge electromagnetic acquisition, analysis, and reporting software developed to take full advantage of the Ectane 3 capabilities. It is a constantly evolving platform boasting powerful data processing tools, multi-technologies support, easy report generation, and an intuitive graphical user interface (GUI). The Ectane 3 can be operated with Magnifi 4.8 or any more recent version of the software.

Learn more

Flexibility for system integration

The Ectane 3 is ideal for semi-automated inspections involving eddy current array (ECA) probes manipulated by a robotic arm or crawler. Multiple analog inputs and outputs are available to facilitate the communication with a programmable logic controller (PLC):

- Five TTL inputs for remote acquisition control

- Three encoder inputs

- Three output relays for system status

- Real-time alarms and data streaming for single-channel probes

- Post-acquisition alarms and data export for array probes

- SDK-compatible acquisition software for inspection sequence automation

High performance probe pusher system

Probot™ is Eddyfi Technologies’ advanced probe pusher-puller compatible with Ectane 3 and Magnifi software. By enabling constant and optimal probe pulling speed, it supports the acquisition of high-quality encoded data. Designed for one-person operation, the Probot is controlled directly through the software interface. The solution ensures precise defect positioning and tackles the most critical heat exchanger inspections with efficiency.

Protect Your Investment. Maximize Uptime. Unlock More Value.

To help you succeed throughout the lifecycle of your equipment, Eddyfi Technologies offers the Customer Success Program (CSP), designed to reduce downtime, boost productivity, and protect your investment.

With varying levels of access tailored to your unique needs, the CSP provides a flexible suite of services including:

- Annual calibrations

- Accidental damage protection

- On-demand eLearning

- Collaborative support tools

- And more!

Whether you're looking for peace of mind, compliance support, or enhanced efficiency, the CSP strengthens our partnership and ensures you get the most from your Eddyfi solution.

Specifications

INSTRUMENT

279.6 × 254.0 × 158.8 mm (11.0 × 10.0 × 6.25 in)

with batteries: 6.8 kg (15 lbs)

without batteries: 5.9 kg (13 lbs)

10 L (610 in3)

100–240 VAC, 50–60 Hz

Direct VAC or onboard batteries

Type: Li-ion, rechargeable, DOT compliant Typical Life: 8 hours

IP65

Sealed and fanless

3 axes, quadrature with individual reset line

Start, stop, balance, next file and more

1000 BASE-T

Automatic for Surface Array probes

0–45°C (32–113°F)

95%, non-condensing

EN 61010-1, CE, FCC Part 15B, ICES-003, AS/NZS, CISPR 22, RoHS, ASME

4–8

64, 128 or 256

5 Hz–10 MHz

Up to 20 Vpp

ECT

Up to 160

2

Simultaneous and continuous

41 dB range, 23–64 dB

16 bits

Up to 50 000 samples/s

RFT AND NFT

5

2

50 dB range, 26–86 dB

MFL

41 dB range, 18–59 dB

IRIS UT

1, pulse-echo

0–200 V drive 0–70 dB (1 dB steps) 0–40 dB DAC

4 user-selectable filters 25 MHz system bandwidth

5–20 MHz

12 bits, 100 MHz

Up to 26 kHz

Real-time A, B and C-scans

Up to 100 RPS

ECA, TECA, NFA

Single or Double 160–pin Array

SmartMUX

RFA

5 Hz to 2 kHz

2

41 dB range, 23–64 dB

41–pin connector