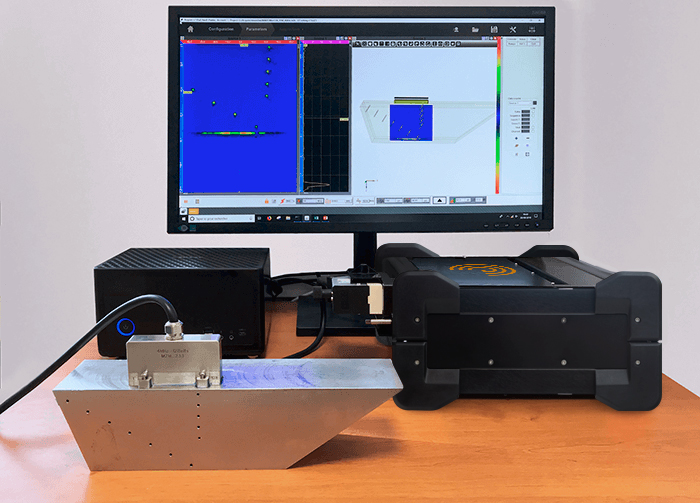

For integrators, manufacturers, industrial labs, and NDT service providers, Panther™ 2 by Eddyfi Technologies is the ultimate phased array ultrasonic testing (PAUT) instrument with a complete total focusing method (TFM) toolbox delivering data results faster than any other commercially available solution. With advanced inspection data results made accessible with a complete software ecosystem to suit specific needs, including an open software development kit (SDK), Panther 2 is your go-to for flexible and scalable testing requirements.

Details

Designed For Industrial Environments

Well suited for a wide range of diverse inspection applications common across industries such as aerospace, oil and gas, and metallurgy, the second-generation Panther is built to perfection and built for perfection. This is evident with:

- Reinforced bumpers that offer unit protection and convenient stackability

- Flexible toolbox that enables adaptability for unique inspection requirements

- Automation to streamline the inspection process

- Exclusive flash mode that fits industrial productivity requirements.

Fastest Data Throughput

Panther 2 is uniquely equipped with a 320MB/s high-speed link for the fastest data throughput possible:

- up to 5 meters (16 feet) with USB3 cable

- or up to 30 meters (98 feet) with RJ45 cable and USB to ethernet hub

See More... Book A Panther 2 Demo!

Ready, Set... Done!

We understand that time is money and optimizing your quality assurance investment starts with high productivity. That’s why Eddyfi Technologies introduced “flash” modes making Panther 2 an astounding 10+ times faster than any other commercially available phased array test instrument. Why settle for anything less?

Probe Number Limit: None.

With configurations from 32 up to 2,048 elements, the adaptability of Panther 2 enables scalable automated NDT inspections. The compact unit can be daisy-chained with up to 16 units in parallel and 256-element active aperture, offering a substantial increase in inspection speed.

Ask an Expert

Desktop TFM For A Deeper Data Dive

Acquire™ is Eddyfi Technologies’ acquisition software delivering advanced PAUT and TFM settings and incredible imaging. It was designed for both industrial and laboratory applications, also allowing research and development teams to create customized NDT techniques, and new inspection methods. Acquire software includes a comprehensive PAUT and TFM toolbox, powered by CIVA NDE simulation software. It works with:

- Various type of components including 2D and 3D import

- Most PAUT probe types (including matrix, sparse array, daisy, dual linear array (DLA)/ dual matrix array (DMA), and more)

- Highly customizable TFM setups to evaluate your own ideas including plane wave imaging (PWI) pitch/catch, full matrix capture (FMC), image fusion, tailored propagation modes, conversion modes, adaptative reconstruction, etc.

- Elementary A-scan access at your convenience

- CIVA simulation to experiment acquiring your own solution.

No Need To Learn The Hard Way: Software Your Way

Eddyfi Technologies’ software development kit is a high-level library that allows users to quickly develop their own NDT inspection applications to control Panther 2 with access to all acquisition parameters, as well as real-time conventional, PAUT, and TFM data, and/or saved data for post processing.

SDK advantages include:

- Rapidly developed basic automation functionality

- OS/language independent

A Complete Software Ecosystem

Acquire software offers partial embedding of CIVA software for simulation and setups, ensuring complete compatibility with CIVA and ULTIS for advanced analysis. Additionally, Capture™, reliable and proven software already powering the portable Mantis™ and Gekko® instruments, is also fully compatible with Panther 2 for both acquisition and analysis. This seamless compatibility between the software enables higher productivity and efficient data processing as Capture is capable of reading Acquire data files. With Panther 2, powered by industry-leading software, you can tackle any type of inspection with ease.

Protect Your Investment. Maximize Uptime. Unlock More Value.

To help you succeed throughout the lifecycle of your equipment, Eddyfi Technologies offers the Customer Success Program (CSP), designed to reduce downtime, boost productivity, and protect your investment.

With varying levels of access tailored to your unique needs, the CSP provides a flexible suite of services including:

- Annual calibrations

- Accidental damage protection

- On-demand eLearning

- Collaborative support tools

- And more!

Whether you're looking for peace of mind, compliance support, or enhanced efficiency, the CSP strengthens our partnership and ensures you get the most from your Eddyfi solution.

Exclusive Content

Weld Inspection Paparazzi | World Pipelines Article

This exclusive content discusses the use of ultrasound imaging techniques for inspecting pipe welds of varying conditions.

Specifications

INSTRUMENT

298 × 220 × 159 mm (11.7 × 8.7 × 6.3 in)

6 kg (13.2 lbs)

-10-50°C (14-120°F)

-10-60°C (14-140°F)

IP20 (IP54 with accessory)

110–240 VAC, 50–60 Hz

32:128PR, 64:64PR, 64:128PR, 256:256PR with or without TFM

PULSERS

30 ns to 2,000 ns

Maximum 100 V with 1 V step

Up to 30 kHz

RECEIVERS

50 Ω

0.4-20 MHz

1.8 Vpp

Up to 120 dB (0.1 dB step)

< 50 dB

Ultralow noise amplifier

ACQUISITION

800% amplitude range

Hard drive limit

Time, event, encoder

USB3 or RJ45 cable

ANALYSIS

A-scan, B-scan, C-scan, D-scan, echodynamic, top, side, front, 3D

CAD geometry with CIVA™**

Capture, CIVA and ULTIS™**

Up to 800%