State-of-the-Art RFT—Meeting the Ferromagnetic Tube Challenge

Ferromagnetic heat exchanger tubing found in petrochemical plants cannot be inspected with conventional eddy current techniques. Common inspection techniques for this material include IRIS, Magnetic Flux Leakage (MFL), and Remote-Field Testing (RFT). RFT is generally preferred due to its defect sizing capabilities, decreased need for tube cleanliness, and high inspection speeds.

Although the RFT technique is widely accepted, it is often difficult to master. The permeability of carbon steel tubes is an unknown parameter that can change considerably from heat exchanger to heat exchanger and, at times, within the tubes of the heat exchanger itself. Developing sets of calibration standards with different degrees of permeability is not a functional or a financial option. This application note shows how innovative software features allow working around this and other traditional difficulties.

The Challenge

- Overcome the difficulties encountered when using RFT in ferromagnetic heat exchanger tubes.

RFT is a through-transmission technique where the magnetic field travels twice in the tube wall, which induces important amplitude attenuation and phase lag.

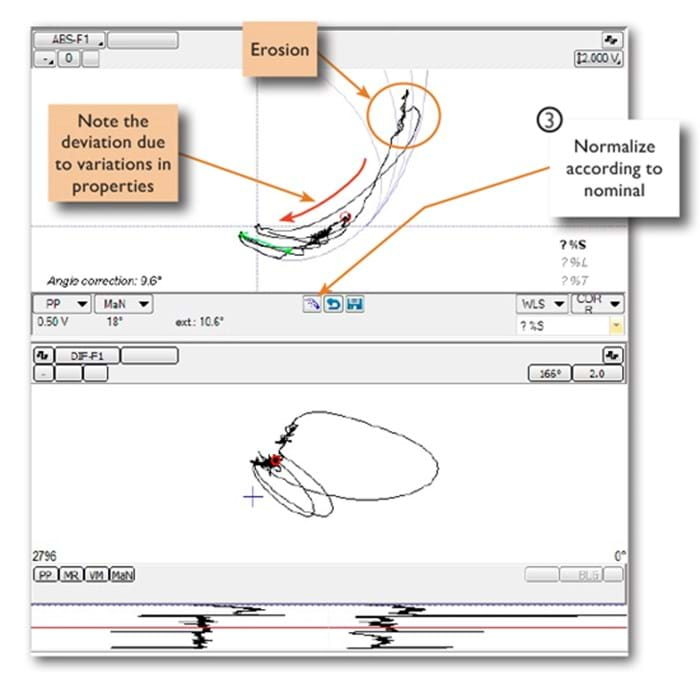

This double diffusion in the tube wall makes the RFT technique very sensitive to any nominal thickness variations and permeability change. This high sensitivity brings several challenges:

Typically, the manufacturing thickness tolerance of carbon steel tubes is approximately 10%. But such a variation in thickness can represent a rotation of about 60° on your channel, which greatly affects sizing interpretations.

The magnetic permeability of carbon steel varies from grade to grade and according to processing history—tubes processed at high temperatures do not have the same permeability than those processed at low temperatures. Such variations in permeability have a considerable impact on RFT sensitivity and depth sizing.

Calibration tubes matching the properties of tubes to inspect are extremely hard to come by. Differences in thickness and permeability almost always make calibrations inadequate without the proper tools to compensate.

The Solution

- Innovative software features to work around those difficulties.

The shortcomings of RFT can be worked around with software features, such as those found in the Magnifi® acquisition and analysis software.

The software makes use of the standard impedance plane and an absolute voltage plane. The impedance plane has proven an efficient tool to detect and characterize small volumetric defects through standard techniques. The absolute voltage plane, on the other hand, enables more precise characterization of large volumetric defects. Using both planes in concert allows improved detection, sizing, and characterizing a wider range of defects.

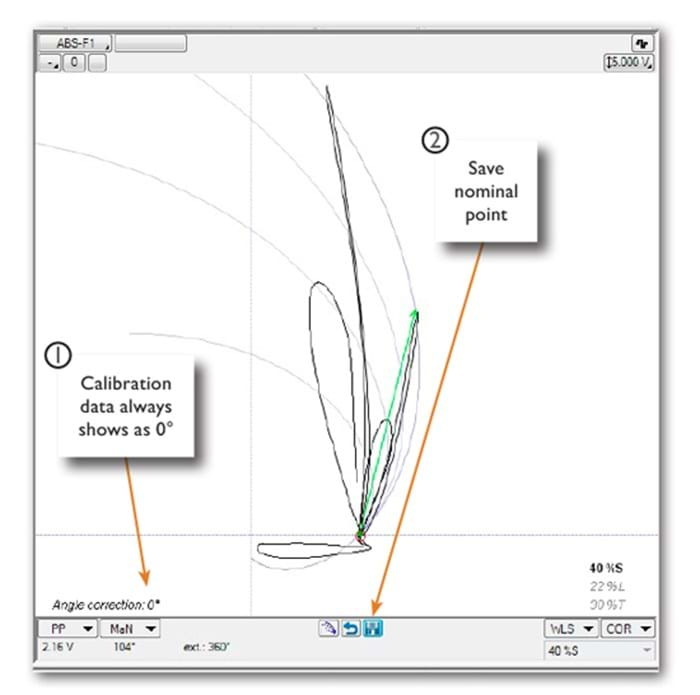

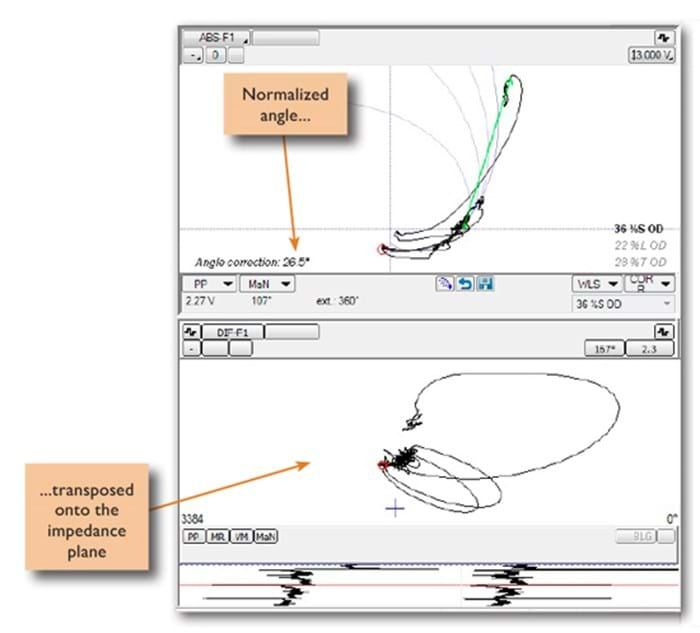

In addition, Magnifi is capable of saving the balanced, nominal operating point. This stored value creates a reference point that enables tube-to-tube tracking of permeability variations. Normalizations are automatically applied to each channel in an effort to improve accurate defect sizing.

Magnifi also issues warnings when the effects of magnetic permeability variations are too large to normalize. In this case, users can adjust the inspection frequency to compensate for magnetic permeability differences between the calibration standard and the tubes in the bundle.

An additional Magnifi feature is the automatic detection of landmarks. This provides accurate defect positioning without the need for an encoder.

Un-normalized field data acquired with single-driver RFT probe

Normalized field data acquired with a single-driver RFT probe

Benefits

- Faster, more accurate RFT inspection results that are easier to analyze, translating into concrete time and cost savings.

The value added by software-enhanced RFT is easy to see: one-click normalization of all channels, automatically generated sizing curves, and normalization tracking enable easier, faster, and more precise characterization of small and large volumetric defects. This translates into higher-quality inspections that provide much needed information to asset owners.

Eddyfi Technologies is constantly innovating, building on its already extensive electromagnetic expertise. With the help of our wide-ranging customer base, we continue to further improve RFT technology.