Panther™ 2: The High-Speed Inline Ultrasonic Inspection Solution

Ask an expertWhen it comes to inline inspection of components such as plates, bars, tubes or composite materials, industry standards impose stronger requirements in terms of detectability. This often implies the use of ultrasonic systems and turnkey solutions that provide high sensitivity and repeatability with productivity that matches the throughput of production lines. And while phased array ultrasonic testing technology has long been employed to address these issues, a Beyond Current solution takes productivity to new levels.

The Challenge

Performing inline inspections with standard phased array ultrasonic testing systems proves inefficient due to the necessity of waiting for the ultrasound to complete its traversal and return to the probe before initiating the subsequent electronic sequence.

When conducting inline ultrasonic testing of various components like plates, tubes, bars, and composites, manufacturers must adhere to industry standards that demand comprehensive volume inspections while ensuring the necessary sensitivity, repeatability, and productivity to meet customer expectations. To fulfill these requirements, integrators commonly employ phased array ultrasonic testing, or PAUT, systems that offer electronic steering and scanning capabilities. These systems electronically steer and scan an ultrasonic beam across the aperture of the phased array probe, enabling high-speed inspections. However, despite these advancements, the systems are still constrained by a physical limitation: the need to wait for the ultrasound to traverse the entire component and return to the probe before initiating the next electronic sequence. This limitation poses a particular challenge when inspecting thick components.

The Solution

An advanced ultrasonic testing system offers high-speed inspections, reduces electronic sequences, achieves unparalleled scanning speeds, and maintains sensitivity and repeatability through innovative scanning modes.

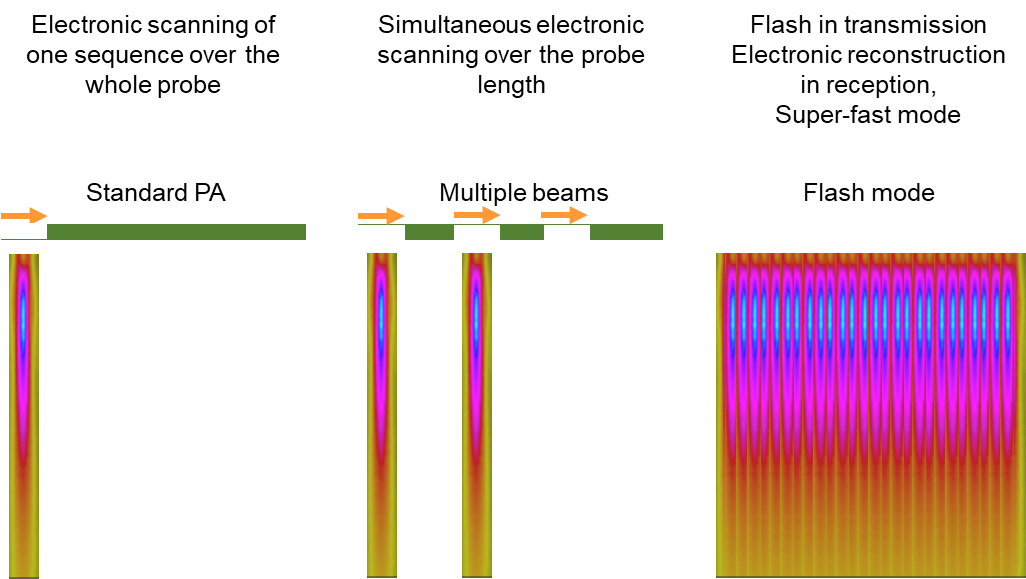

The Panther™ 2 phased array ultrasonic testing instrument by Eddyfi Technologies revolutionizes scanning speed, offering a tenfold improvement over conventional inspection systems. To achieve this, the PAUT instrument reduces the number of electronic sequences required for inspections. Equipped with advanced inspection modes, the Panther 2 enhances scanning speed beyond standard linear scans used by other PAUT systems. It introduces two innovative modes: mixed modes, which simultaneously fire up to eight electronic sequences instead of a single one, and a super-fast mode that fires all array elements simultaneously while performing an electronic reception scan.

The solution presents an unrivaled scanning speed for inline applications while ensuring exceptional sensitivity and repeatability. The following scanning speed examples achieved using a single unit with mixed and flash modes highlight their notable advantages over a simple linear scan.

Benefits

- Manufacturers benefit from faster inspections, improved efficiency, and scalability of their inspection systems through the utilization of multiple units and flexible software development kit, yielding increased productivity and the ability to deliver high-quality products seamlessly.

Increasing inline inspection speeds can also be achieved by expanding the number of systems and probes utilized. The PAUT tool offers exceptional adaptability with configurations ranging from 32 to 2,048 elements, facilitating scalable automated NDT inspections. Its compact design allows for daisy-chaining up to 16 units in parallel, resulting in a substantial boost in inspection speed. Customers can customize their inspection setups by combining multiple Panther units with advanced scanning modes to meet specific application requirements and budgetary considerations. While this increased scanning speed generates a significant amount of data, the Panther 2 addresses this challenge with its ultra-fast Ethernet capability, providing a 10 Gigabit-per-second high-speed link per system using optical fiber up to 200 meters (656 feet) in length.

Moreover, Eddyfi Technologies' software development kit empowers users to rapidly develop their own non-destructive testing inspection applications, granting access to all acquisition parameters, real-time conventional, phased array ultrasonic testing, and total focusing method data, as well as the ability to save data for post-processing.

In summary, the Panther 2 is a highly versatile modular unit available in configurations ranging from 32:128 to 256:256. Its capability to operate with up to 16 units in parallel, combined with a user-friendly software development kit, enables integrators to effortlessly develop tailored solutions for their customers in accordance with industry-standard requirements.

Contact us to learn how to make your inline inspections more productive today!