Assessing Corrosion and Erosion of Distribution Pipeline Systems

Ask an expertPrimary aluminum production plants require extensive networks of pipelines to carry solid particles and liquids throughout the manufacturing process. The integrity of these assets is critical for the production process of aluminum. Unfortunately, these pipeline networks can be prone to various damage mechanisms. For example, internal erosion can occur in pipes carrying abrasive materials such as alumina or coke. In other cases, external corrosion of both insulated and uninsulated lines can also compromise their integrity. In an industry where an unplanned shutdown due to pipe failure means significant downtime and expenses to restart the process, appropriate inspection methods to detect and assess corrosion and erosion are essential. Working around the clock, in-service inspection is also critical to minimizing down time and ensuring smooth operations.

The Challenge

Inspect carbon steel pipe distribution systems found in primary aluminum production without disrupting production.

Figure 1 ALUMINUM ROD INGOTS

Paste plants and cast houses of primary aluminum production plants operate almost continuously. The carbon steel pipelines of distribution systems are used to transport raw materials in plants and manage hazardous liquids and byproducts. Some of these uninsulated systems are subject to Corrosion Under Insulation (CUI), Flow-Accelerated Corrosion (FAC), erosion, and scab corrosion. These damage mechanisms must be identified to prevent unexpected failures and optimize maintenance operations. MISTRAS, an NDT service provider operating in this field for several years, was challenged by a plant owner to efficiently inspect these components while they were in service.

Erosion is one of the damage mechanisms observed in solid raw material distribution systems. The coke distribution pipelines in anode plants are prime examples, in which the calcined petroleum coke is routed from the storage silos to the sieving system and ultimately to the anode paste mixers. Like in flow-accelerated corrosion, the extrados of pipe elbows are the most affected components. For this particular application, carbon steel pipes of 6-millimeter (0.25-inch) thickness were used to transport the coke.

The water used to cool aluminum ingots is transported in 200-millimeter (8-inch) diameter carbon steel pipes with 7.6-millimeter (0.3-inch) thickness. Corrosion scabs and blisters have been observed in the cast house’s wastewater distribution system. These pipes route the wastewater to the water treatment center. Scabs or blister corrosion are a potential threat that must be monitored rigorously to ensure the integrity of the asset and to avoid potential health and environmental issues in cases of hazardous product leaks.

Common techniques to assess corrosion and erosion have intrinsic limitations. Scab assessment with Ultrasonic Testing (UT), for example, requires surface preparation which may be dangerous to perform in-service as it would risk disturbing the remaining material and cause a leak. Preparing the surface therefore requires shutting down the line. Radiography will work on pipe up to 150 millimeters (6 inches) but not on larger diameters, and it presents a health and safety hazard due to the use of radiation.

The Solution

An advanced Pulsed Eddy Current (PEC) solution capable of detecting erosion and corrosion.

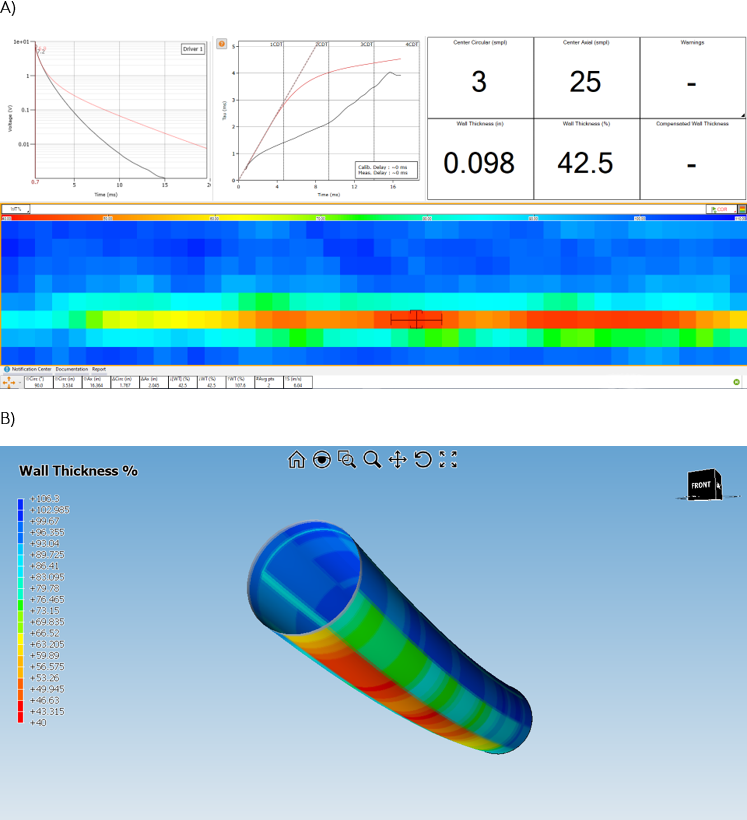

Figure 2 EXTRADOS EROSION ON CASE 1 – COKE DISTRIBUTION SYSTEM. A) LYFT C-SCAN; B) SURFACEPRO 3D

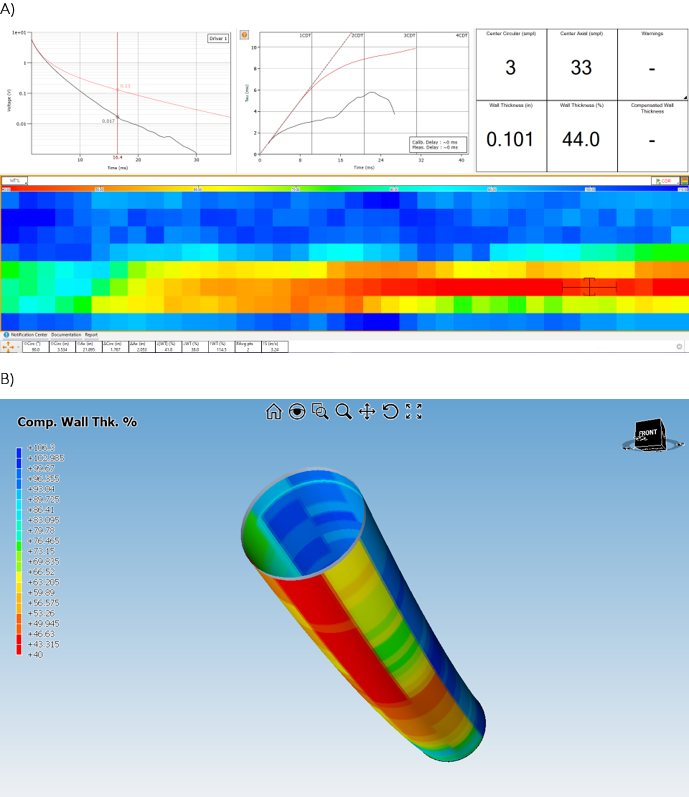

Figure 3 EXTRADOS EROSION ON CASE 2 – COKE DISTRIBUTION SYSTEM. A) LYFT C-SCAN; B) SURFACEPRO 3D

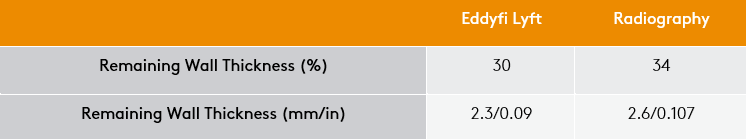

Table 1 SCAB ASSESSMENT USING PEC AND RADIOGRAPHY

The Lyft® pulsed eddy current solution chosen by MISTRAS to address this challenge was specifically designed for this type of application. The technique is now covered by several industry standards such as ISO 20669, API RP 583, and the new ASME section V, article 21. PEC is a versatile inspection technology which provides an average remaining wall thickness through insulation and coatings. The technique can also be used in direct contact with the inspected component on scabs or blisters without the need for surface preparation. Unlike Radiography Testing (RT), PEC does not require access to both sides of the components which makes it a technology of choice for inspecting large pipes and vessels. PEC is a technique resilient to liftoff variations that provides volumetric measurements of remaining material. It is both capable of detecting and assessing general corrosion on the outer surface of the pipes, such as scabs and blisters, and detecting erosion on the inner surface.

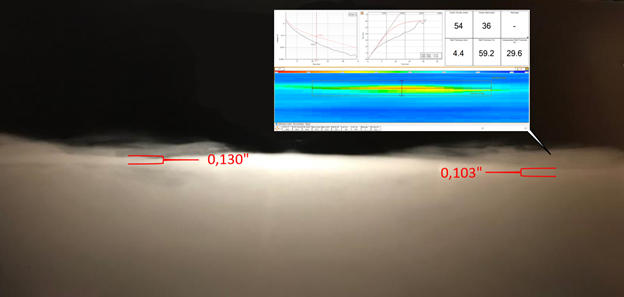

Coke distribution pipelines of roughly 100-millimeter (4-inch) diameter were first inspected. If present, internal erosion damage in the elbows was expected to be well detected in these lines using the PEC-025-G2 mono-element probe. High scanning productivity was achieved, and several lines of data were encoded using a scan rate of approximately 75 millimeters (3 inches) per second with a scan resolution of 17.4 millimeters (0.684 inches) per sample. Two cases (Figure 2 and Figure 3) of extrados erosion are shown here. The inspection results indicated significant wall losses, over 50 percent, in the extrados, which was confirmed afterwards with UT during a maintenance operation.

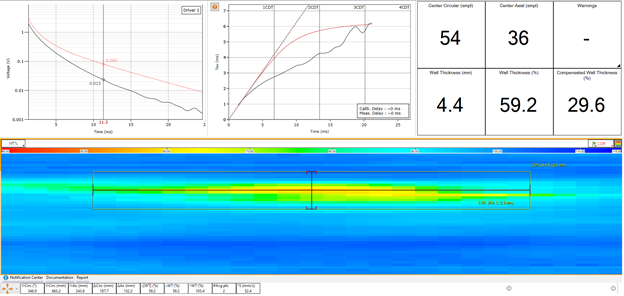

The wastewater distribution systems were also inspected with the PEC-025-G2 probe in dynamic mode. This scan mode, first introduced by Eddyfi Technologies, enables building a C-scan map with encoded data and archiving electronic files that can be reviewed later. The Lyft CPN advanced analysis software also enables the use of an algorithm called the Compensated Wall Thickness (CWT) which allows for more accurate sizing of indications that are smaller than the probe’s footprint. The main purpose of the tool is to provide an estimate of the true remaining wall thickness when assessing a defect. The estimation of the true remaining wall thickness is done with the use of advanced algorithms that extract the contribution from the indication and differentiate it from the signal of the surrounding nominal wall thickness. The end result is a sizing accuracy of ±10 percent of the nominal wall thickness. The inspection results shown in Figure 4 indicate substantial wall loss. Most of the regions affected by blistering were sized at 60 percent WT or 4.3 millimeters (0.177 inches) down to nearly 30 percent using the CWT advanced analysis tool.

This severe wall loss was later confirmed using radiography with results presented on the right of Figure 5 and Table 1.

Figure 4 CRITICAL SCAB EFFECTS ON A PIPE – WASTEWATER DISTRIBUTION SYSTEM

Figure 5 RADIOGRAPHY OF THE CRITICAL SCAB EFFECTS ON A PIPE – WASTEWATER DISTRIBUTION SYSTEM

Benefits

- In-service inspection of the asset: the Lyft pulsed eddy current solution does not require shutting down the distribution systems. All inspections can be done on in-service components, leading to significant cost savings.

- Internal and external corrosion detection: PEC can detect wall thickness variations, whether located on the inner or outer surface of the component.

- Productive inspections: PEC can be used to inspect hundreds of meters of distribution system pipelines. Encoded electronic data is available for review later at any time.

- No need for time consuming surface preparation, increasing the inspection productivity.

- Advanced sizing algorithms provide accurate measurements within ±10 percent of the nominal wall thickness.

The Lyft pulsed eddy current solution can efficiently and precisely address the challenge of assessing erosion in elbows of solid particle distribution systems as well as critical scab corrosion in wastewater distribution pipelines. All inspections were performed on in-service systems, requiring no downtime and allowing a better planification of maintenance operations. The inspection results were confirmed using UT and RT during the maintenance shutdown.

The solution’s benefits are undeniable. Contact our experts to learn more today.