3-Step Tech Solution for Superior Pipeline Corrosion Detection

Ask an expertEnsuring the structural integrity of carbon steel pipelines is of paramount importance to pipeline owners. These pipelines often transport flammable products (liquid or gas) under high pressure, and any leakage can lead to significant environmental damage and potential loss of life. A robust Pipeline Integrity Management (PIM) plan is essential for safe and reliable operations. Asset engineers manage PIM plans, prioritizing the inspection of these pipelines to ensure structural integrity and safety.

The Challenge

Inspecting critical pipelines presents several challenges, including coverage, detection capability, and precision of findings.

Inspecting critical pipelines present several challenges, including:

- Coverage: Determining the extent of the pipeline that needs inspection.

- Detection Capability: Ensuring the inspection equipment can detect flaws and defects.

- Precision of Findings: Accurately identifying and locating defects with detailed information on wall loss.

This application note discusses a strategy to overcome these challenges while optimizing the inspection process to deliver accurate and reliable data. This information allows asset engineers to formulate optimal maintenance and repair strategies, ensuring the continued safe and efficient flow of products.

Pipeline owners seek:

- Confidence that the pipeline is safe.

- Confidence that maintenance and repair strategies are optimal.

- Confidence that the pipeline’s lifespan is maximized and will operate without avoidable downtime.

- Evidence for regulators that the pipeline is fit for service.

To achieve these goals, specialized, field-ready and proven equipment is essential. This equipment must offer:

- Excellent Probability of Detection: The ability to reliably detect and locate defects or potential issues within acceptable sensitivity levels.

- Precise Sizing Capability: The ability to accurately size and classify damage mechanisms, which is key to optimizing inspection intervals and implementing protective measures.

- Excellent Coverage: Comprehensive inspection coverage to ensure no areas are overlooked.

Beyond these equipment prerequisites, it is crucial that the deployed tools are:

- Highly Efficient: Capable of performing thorough inspections quickly.

- User-Friendly: Simple to operate, minimizing training requirements and user errors.

- Complementary to the User: Designed to enhance the user’s capabilities and streamline the inspection process.

The Solution

A seamless, integrated, multi-modality approach ensures comprehensive pipeline inspection without sacrificing any aspect of performance.

Why compromise? The solution to achieving inspection confidence is available today through a seamless, integrated, multi-modality approach. This approach ensures comprehensive pipeline inspection without sacrificing any aspect of performance.

Requirements

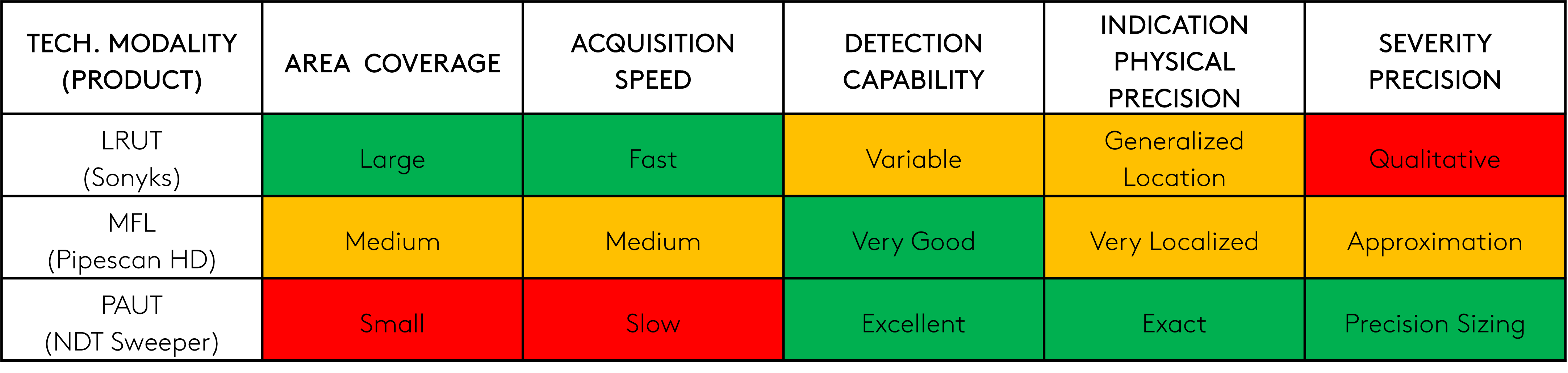

The table below (click to expand) provides high-level comparison of technology modalities, illustrating how they compare and work harmoniously to provide a total inspection solution.

The table above shows that deploying a three-step process utilizing these technologies enables accurate and reliable fitness-for-service assessments. This delivers the confidence sought and effectively addresses all the identified challenges.

Workflow

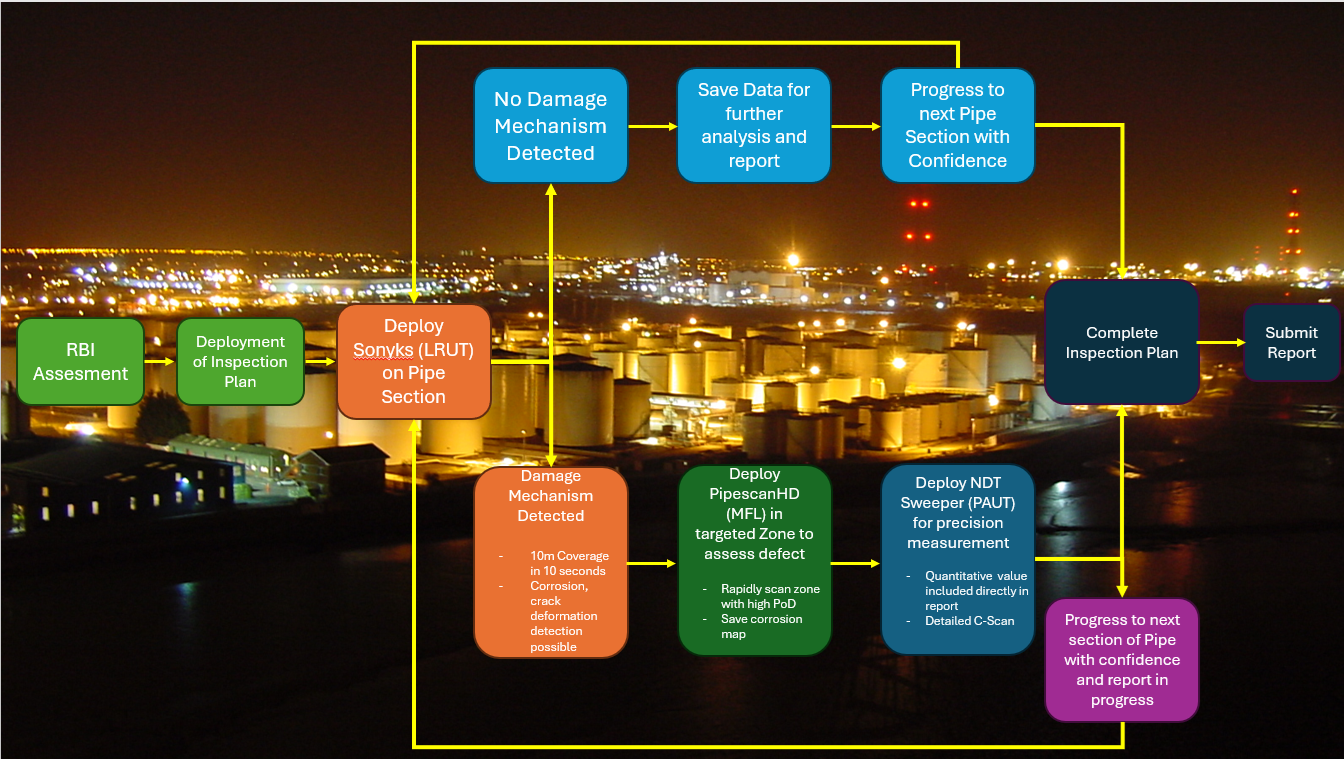

What does the inspection workflow look like in practice? As the decision tree flow below (click to expand) demonstrates, it is surprisingly simple.

The proposed solution is a complementary multi-modality three-stage process designed for simplicity, comprehensiveness, and clear, actionable reporting. This process includes:

1. Long-Range Ultrasonic Testing (LRUT) with Sonyks™

- Coverage: High

- Speed: Fast

- Detection: Capable of detecting corrosion, cracks, and deformations

- Precision: Generalized location

- Severity: Qualitative

2. Magnetic Flux Leakage (MFL) with Pipescan™ HD

- Coverage: Medium

- Speed: Medium (1m/s or 3.28ft with a 198mm or 7.8in scan width)

- Detection: Very good, detecting top and bottom surface defects down to 2mm (0.08in) in diameter

- Precision: Localized, identifying defect positions within 4mm (0.16in)

- Severity: Approximation, with severity implied by signal response

3. Phased Array Ultrasonic Testing (PAUT) with NDT Sweeper

- Coverage: Low (comparatively)

- Speed: Slow (comparatively)

- Detection: Excellent

- Precision: High, identifying defect positions within 1mm (0.04in)

- Severity: Precision sizing (quantitative)

By integrating these three modalities, pipeline integrity engineers can ensure thorough inspections, maximize detection capabilities, and achieve precise severity assessments without compromising coverage or speed.

Learn more

Benefits

- The benefits of this multi-modularity approach are clear. Pipeline owners gain unparalleled confidence in the safety and reliability of their assets, ensuring continuous operation without downtime.

The benefits of adopting a multi-modality three-stage inspection process are clear. This approach effectively addresses challenges related to coverage, detection, precision, and severity, providing a comprehensive solution. Moreover, these challenges are met with easily deployable, fast, and efficient technologies capable of detecting and sizing defects under insulation and through coatings.

Implementing such a strategy results in accurate and reliable fitness-for-service assessments, enabling asset owners to develop optimal Pipeline Integrity Management (PIM) plans. This ensures a safer, more efficient pipeline operation and contributes to longer asset lifespan and reduced maintenance costs.