Delivering powerful, flexible, and intuitive reporting tools, SIMSTM PRO is the missing piece of the puzzle for storage tank inspection, encompassing data analysis, and reporting into one straightforward software. Integrating seamlessly with SIMS GO data acquisition software, SIMS PRO delivers thorough and comprehensive tank bottom inspection reports that are customizable to meet all the global inspection needs in the most efficient manner possible.

Download SIMS

Details

Determining the true integrity of tank bottoms

SIMS PRO has been developed with customer feedback and engagement to provide a tank bottom reporting solution that adheres to the modern inspection demands, including those outlined in EEMUA 159 and API 653.

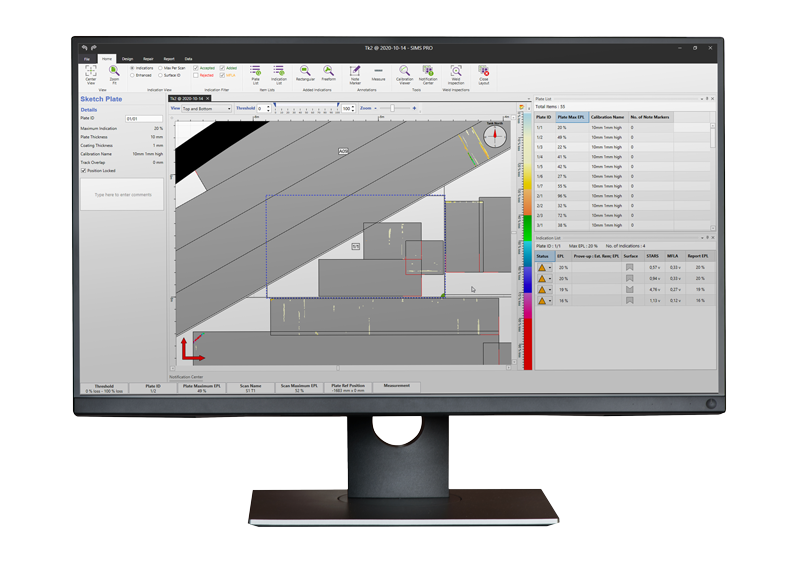

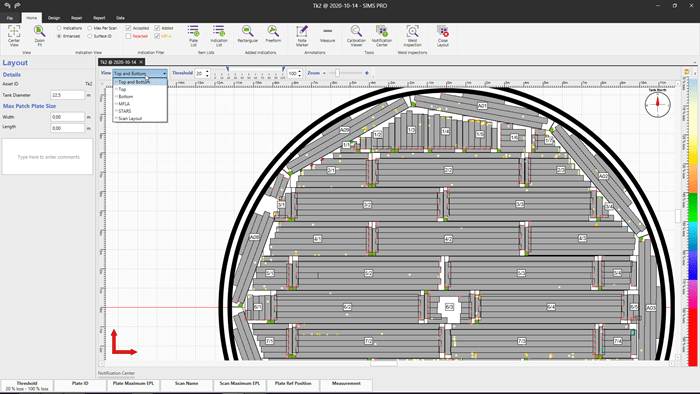

Seamlessly integrating with the Floormap®X, SIMS PRO automatically displays the inspection data intuitively and immersively to provide a clear integrity image of the tank bottom.

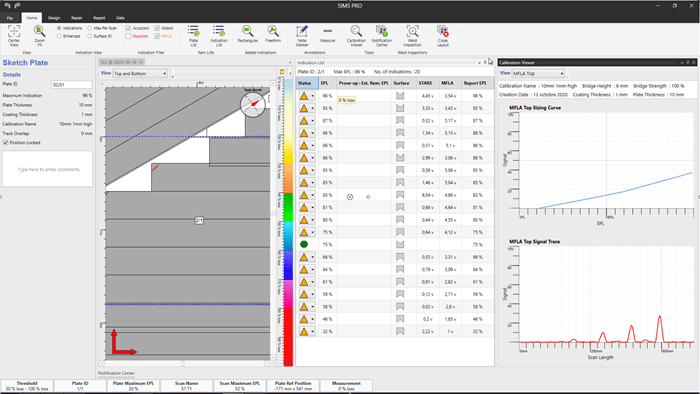

SIMS PRO displays high-resolution mapping views captured by FloormapX, including detailed color-coded severity maps and full resolution MFL and STARS data views across the entire tank.

Benefits:

- Generate EEMUA and API compliant reports with automated software tools.

- Extend inspection intervals, report data as low as 10% material loss.

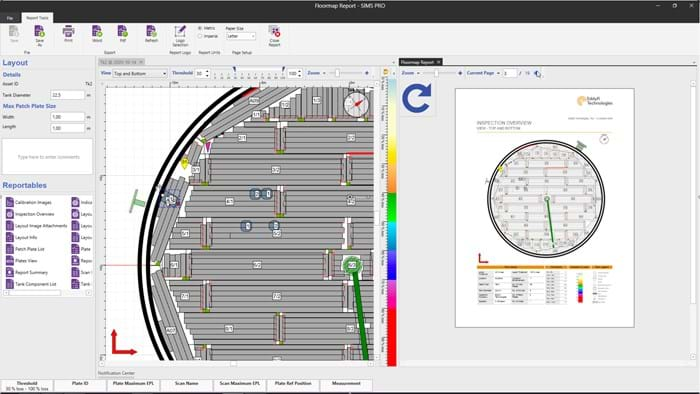

- Standardized company reporting with customizable report templates.

- Reduced reporting times with automated indication lists.

- Paperless reporting from the tank to the customer. Export reports as a PDF, Word, or Excel file.

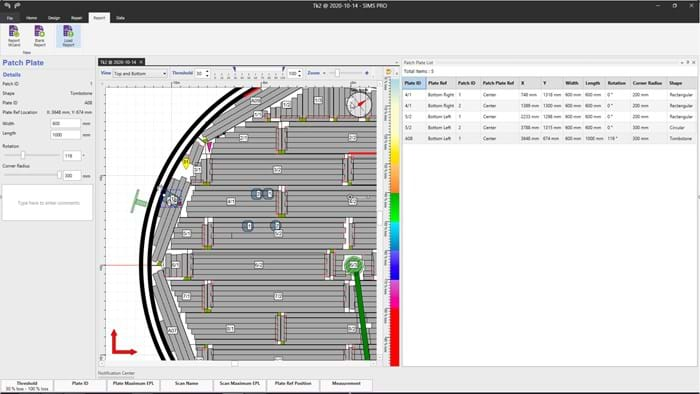

- No 3rd party software required with integrated, comprehensive tank builder and patch plate designer.

- Backward compatible with the ability to import Floormap3Di data.

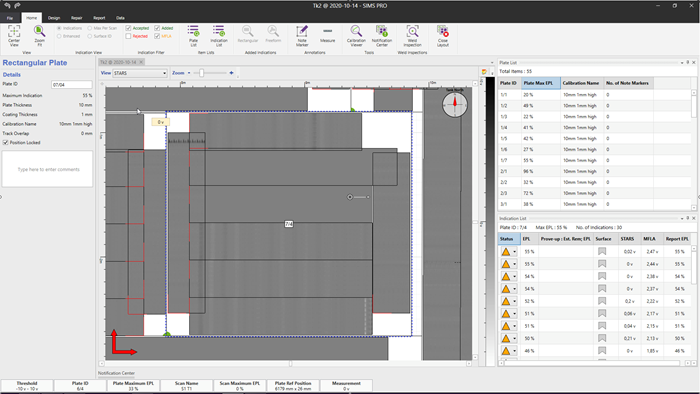

Capable of displaying MFL indications as small as 10% material loss, SIMS PRO provides an early alert to the presence of corrosion, which is essential for devising optimal maintenance and repair strategies. This additional data supports more informed calculations to extend inspection intervals confidently.

Features

- View 100% of the captured RAW MFL array and STARS data

- Fully editable comprehensive automated indication list

- Intuitive navigation with minimal button click approach

- Multiple c-scan analysis views and complementary tools

- Comprehensive and customizable report builder

- Simple, flexible, and intuitive repair plate design

Data Views

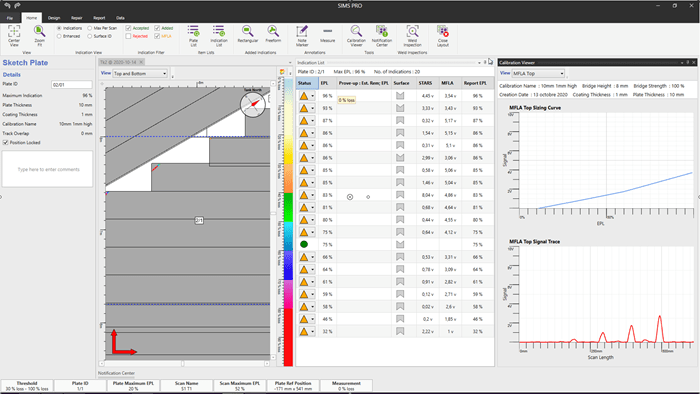

SIMS PRO displays various high-resolution data views. Color-coded severity maps provide the user with a quick overview of the tank condition. Users can manually zoom in to an area of interest or click on a defect in the indication list for detailed analysis and evaluation. Users can switch between top and bottom side, only topside, or only bottom side view. 100% of the RAW MFL and STARS data captured by the FloormapX is viewable within SIMS PRO, allowing users to view indications as low as 10% material loss.

Fully Automated Indication List

An interactive plate and indication list help in identifying the location of detected corrosion. During the analysis process, the indication status related data can be updated to captured, rejected, or proved-up and include results from complementary techniques via a non-destructive editing process to ensure maximum accuracy while maintaining full inspection audit trails. All information entered into SIMS GO during the inspection process is transferred into SIMS PRO during the import process.

Analysis Tools

The high-resolution mapping images provide an estimated percentage that can be filtered based on indication status and threshold level, meaning corrosion rates, remaining life calculations, and repair cost analyses can be performed to formulate the optimal strategies.

Calibration traces

SIMS PRO automatically imports calibration traces from the inspection. Viewing and including the calibration files in the final report increases traceability, repeatability, and inspection confidence for both the inspection company and asset owner.

Tank Design and Repair

Automated Tank Floor Layout with no CAD necessary. Tank components can be dragged onto the layout to represent the internal features and obstructions such as sumps, supports, and manways. Drag and drop repair plate design features allow for rapid creation of a list containing the required repairs in order for the tank to resume service as fast as possible.

Report Composition

Allowing inspection companies to produce client-specific report format templates ensures consistency, quality, and efficiency. Such is the power of SIMS PRO that provides for the customization and standardization of reports meaning comparisons, and decisions can be made sooner and made with confidence.

SIMS PRO effectively introduces the first truly paperless reporting strategy to the industry, with a seamless user interface that generates the final report without picking up a pen.

Increase Your Productivity

The patented Floormap®X is the only MFL Array tank floor scanner with such an unprecedented efficiency and the ability to address almost any tank out there. Combined with SIMS PRO, it is the leading solution in its category to deliver accurate floor mapping reports, in the most efficient manner, find smaller defects to take immediate actions, and extend inspections intervals.

Learn more