At Eddyfi®, we strive to meet the most rigorous requirements.

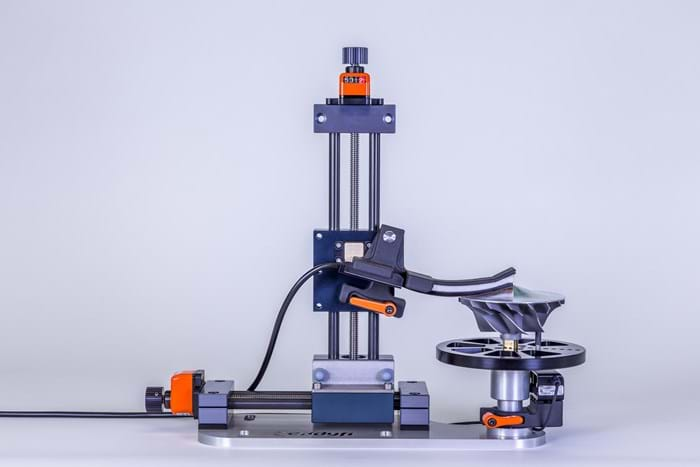

We offer custom Eddy Current Array (ECA) turn-key solutions to address the most challenging applications. Customized sensors and casings provide optimal performance for specific applications and remote deployment.

Details

Our expertise, skilled engineers, and manufacturing capabilities enable us to take almost any set of custom inspection requirements—dimensions, diameters, geometries, number of coil rows, topologies—and turn them into practical and high-performance solutions for you.

Ask an Expert

We’ve had the opportunity to demonstrate this by developing such ECA probes and accessories for applications such as:

- Ship hull inspection

- Internal inspection of pipes and penstocks

- ROV underwater deployment

- Tight radii (turbine grooves, jet engine blade roots, etc.)

- Small cracking on inner walls of tube and pipe (SS liner in chemical loop reactor, pipeline cladding, artillery, etc.)

- Boreholes and boltholes on large steam turbines

- Threads

- Orbital welds

- Turbo blades and disks

- Submarine hull (inspection through acoustic/anechoic tiles)

- and many more

The solutions are not only customizable for specific geometries, but also for specific detection requirements. High channel count probes with small sensors for tiny cracking or large coils to detect cracks in bridge decks plates through asphalt, these are only examples of the type of request that make us thrive. Talk to us about your custom probe needs.

We also offer complete lines of standard surface ECA probes and tubing probes that address most typical surface and tube inspection applications.