Eddyfi Technologies provides the highest performance non-destructive testing (NDT) inspection technologies in the world, helping OEMs, asset owners and service companies enhance productivity, save lives, and protect the environment. We focus on offering advanced phased array ultrasonic testing, eddy current array, and other ultrasonic and electromagnetic equipment including instruments, sensors, software and robotic solutions to key industries such as aerospace, energy, mining, power generation, and transportation.

About UsFeatured Blog Post

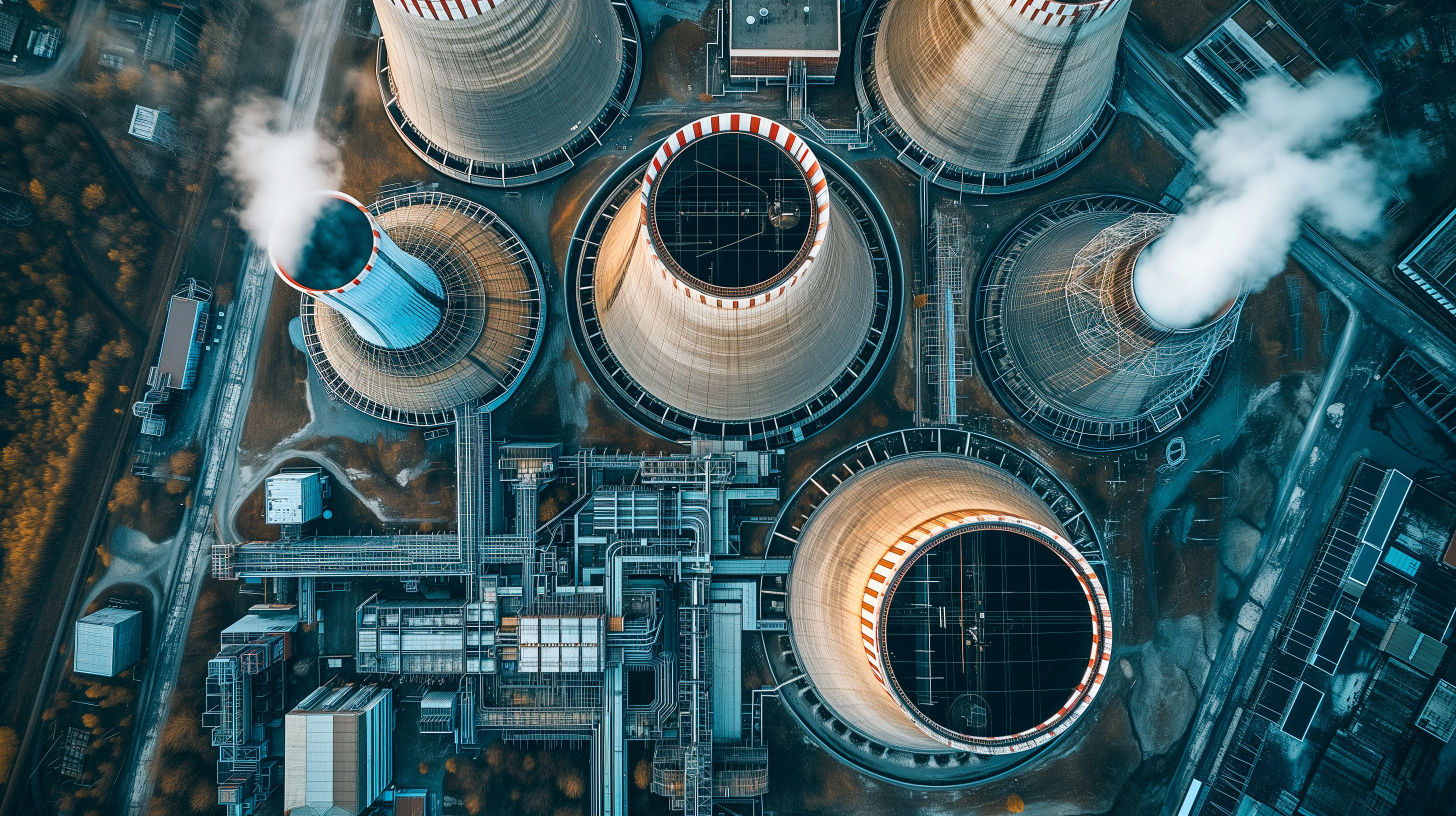

Beyond the Core: Advanced Inspection Solutions in Nuclear Power Plants

Upcoming Event

Eddyfi Technologies at CONTROL 2025

Welcome to Eddyfi Technologies' presence at CONTROL 2025, the leading international trade fair for quality assurance, happening in Stuttgart, Germany, from May 6 to 9, 2025. Join us as industry professionals from around the world come together to explore the latest advancements in quality control, inspection, and NDT.

Other Featured Events

-

Eddyfi Technologies at PANNDT 2025

June 9, 2025

Eddyfi Technologies is proud to participate in PANNDT 2025, the Pan-American Conference for Non-Destructive Testing, hosted by CINDE in Niagara Falls, Canada, from June 9 to 12, 2025. This event brings together NDT professionals, researchers, and industry leaders from across the Americas to explore the latest advancements in inspection technologies and applications.

-

Eddyfi Technologies at ILTA 2025

June 9, 2025

Join Eddyfi Technologies at ILTA 2025, the leading event for the liquid terminal industry, happening in Houston, Texas, from June 9 to 11, 2025. Connect with professionals from across the terminal operations, storage tank, and logistics sectors to explore the latest innovations in safety, inspection, and asset integrity management.

-

Eddyfi Technologies at MegaRust 2025

June 10, 2025

Welcome to Eddyfi Technologies' presence at MegaRust 2025, the premier event for naval corrosion control, taking place in Hampton, Virginia, USA, from June 10 to 12, 2025. This is where key players in the naval maintenance and corrosion industries gather to share insights, explore innovations, and shape the future of shipboard integrity.