Complete Inspection Solutions for Crack Assessment of In-ditch Carbon Steel Pipelines

Pipeline Integrity Solutions

Pipelines are the most efficient way of transporting large quantities of liquids and gas. Their safety is critical and assessing fatigue cracks and stress-corrosion cracking is essential.

Details

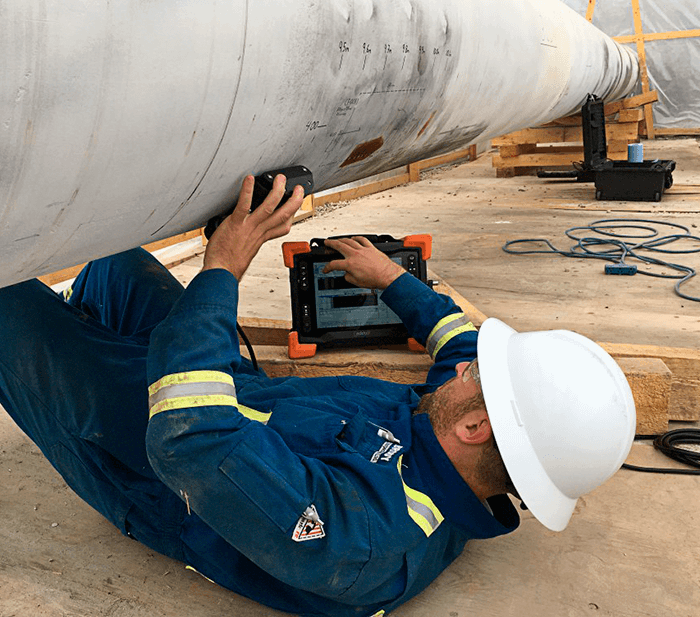

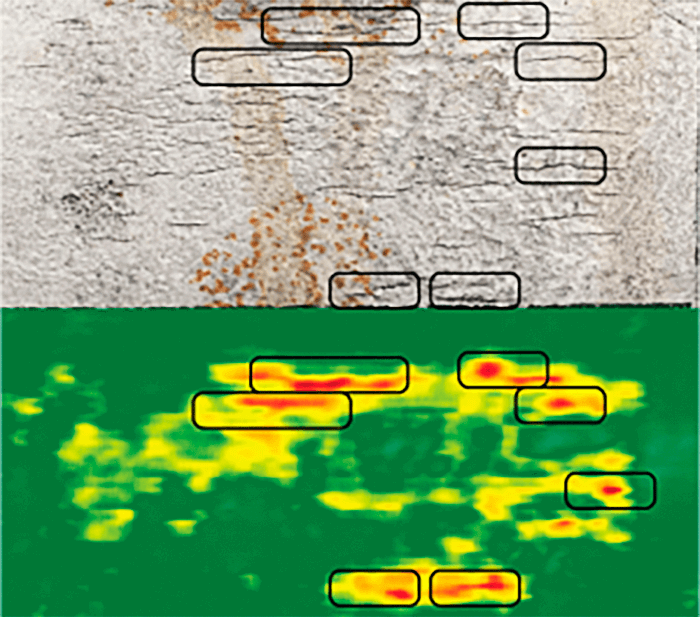

Spyne™, an adaptable surface Eddy Current Array (ECA) screening tool, is specifically engineered to maximize productivity for the detection of Stress-Corrosion Cracking (SCC), cracks, subsurface defects, and pitting in various critical components such as high-pressure gas pipes, vessels, tanks, pipelines and more. With a higher PoD than MPI/PT and with its ultrafast capabilities, it paves the way to unprecedented efficiency.

- Faster, less operator-dependant than PT/MT

- Very high PoD: leave no crack behind

- Repeatable and reliable results

- Minimal surface preparation required; no need to remove coating

- Pre-calibrated. Only cal-check required.

- Combined with Magnifi®: assisted detection and on-the-spot reporting

- Data archiving

- Compatible with a wide variety of flexible-PCB probes, coils diameters, and topologies

Magnetic-Particle Inspection (MPI) and Liquid-Penetrant Inspection (LPI) are often used effectively to detect cracks. They are, however, impractical with known drawbacks—surface preparation, manual length sizing, lack of digital data. Sharck™ probes are designed around Tangential Eddy Current Array (TECA™), a better way to scan for fatigue cracks and Stress-Corrosion Cracking (SCC). Use with the portable Reddy® test instrument, this is one of the most powerful integrated solution for pipeline integrity on the market.

Using TECA Technology to Assess Cracks in Pipelines, Instead of MPI or LPI, You Benefit From:

- Fastest solution on the market

- Surface-breaking cracks detection and sizing in one scan

- Interlinking cracks detection

- Easy to set up solution

- Simple calibration

- Very repeatable results

- Less user dependence

- Single-user operation with Reddy

- In-service inspections

- Solution unaffected by weather conditions

- No surface preparation necessary

- User-friendly interface with data analysis assistant

- Complies with NACE Standard Practice SP0204

TECA Technology

TECA offers a better response to surface-breaking cracks in carbon steel welds than other inspection methods because of the tangential arrangement of its array coils. TECA-induced eddy currents flow perpendicular to the direction of the scan. When eddy currents meet longitudinal cracks, they are forced to go around them by diving under or going around their extremities.

Want to Learn About Sizing Stress-corrosion Cracking?

Our resident experts Michael Sirois, Mathieu Bouchard, and Angélique Raude highlight the importance of highly accurate depth sizing of SCC in pipelines. Read SCC: When Depth Sizing Matters in the July 2017 edition of World Pipelines.

Sharck HR Buttweld