Maximizing the Transmission of Critical Asset Data Using Long-Range Crawlers in Underground Piping Inspections

Ask an expertWhen it comes to maintaining the infrastructure beneath our feet, underground piping often doesn't get the attention it deserves. These buried systems are essential for transporting water, gas, and wastewater, yet they operate out of sight and, consequently, out of mind. Neglecting regular inspections of underground pipes can lead to severe issues ranging from environmental damage to costly repairs. In this application note, we’ll explore the challenges associated with underground piping inspections and how VersaTrax™ crawlers provide a data-rich solution to these problems.

The Challenge

Aging underground piping infrastructure poses significant risks, including leaks, contamination, and explosions. Regular inspections are critical but challenging due to the complexity and costs involved in accessing these buried systems.

As underground piping infrastructure ages worldwide, the need for extremely detailed inspections is becoming more apparent and crucial. Aging underground pipe infrastructure lead to various serious issues, including gas leaks, water contamination, and even catastrophic explosions. Additionally, problems such as corrosion, pitting, and cracks can develop over time, further weakening the integrity of these systems.

Addressing issues with underground piping is often more expensive when problems are left unaddressed. When pipes are regularly inspected, potential issues can be identified early, allowing for timely repairs that are generally less costly. However, when pipes are allowed to deteriorate, the extent of the damage can become severe, leading to more complex and expensive repairs. Furthermore, emergency interventions, triggered by sudden pipe failures, often come at a premium, significantly increasing the financial burden on asset owners.

However, inspecting underground piping is complicated by the high costs and logistical challenges of excavation. This often results in pipes being inspected only at accessible dig sites rather than along their entire length. In the United States alone, there are hundreds of thousands of miles of underground pipes, many of which traverse varying elevations and grades, making comprehensive inspections even more challenging.

While underground piping may be out of sight, the problems associated with it are far from invisible.

The risks of neglecting regular inspections include increased likelihood of:

- leaks

- environmental harm, public health hazards

- structural failures

- higher repair costs

- potential non-compliance with regulatory standards

Therefore, regular inspections are not merely a precaution but a vital component of maintaining the safety, efficiency, and longevity of our underground infrastructure. By prioritizing these inspections, asset owners and municipalities can prevent costly issues and ensure that their underground systems continue to function effectively and safely.

Maintaining an inspection schedule may require some effort and investment, but the long-term benefits far outweigh the risks of neglect.

The Solution

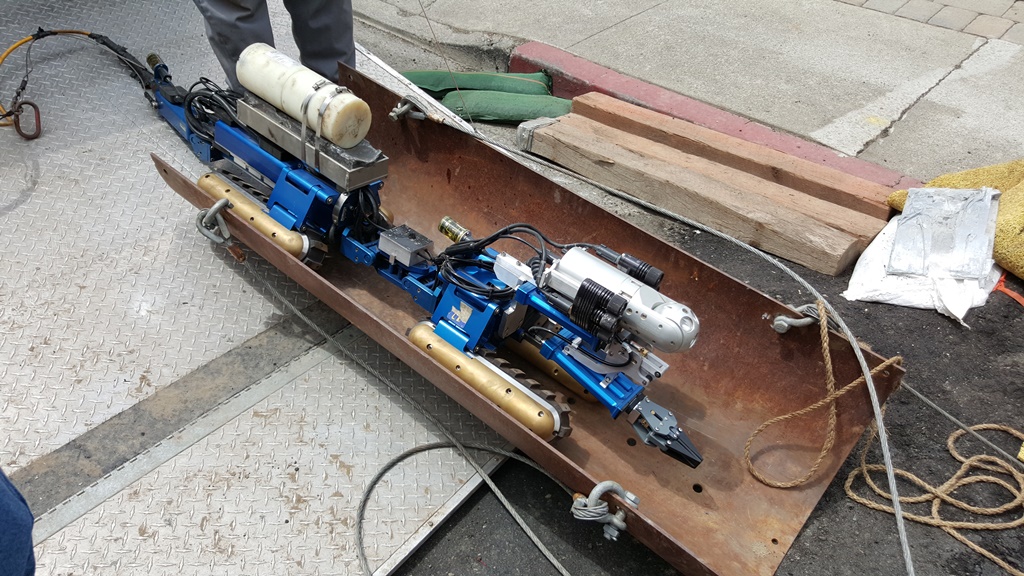

VersaTrax pipe inspection crawlers offer a high-tech solution for detailed inspections of underground piping, integrating advanced fiber optic tethers to enhance data transmission and inspection accuracy.

VersaTrax pipe inspection crawlers are sophisticated robotic devices equipped with cameras and sensors designed to navigate the interior of pipelines, assessing their condition in real time. These inspection crawlers are built to operate in confused spaces and can traverse pipes of various sizes and materials, offering unparalleled visual and diagnostic data to inspectors above ground.

The integration of advanced technologies like fiber optic tethers has significantly enhanced the capabilities of VersaTrax crawlers, revolutionizing how underground pipelines are inspected. Fiber optics bring a range of benefits, including superior data transmission, that are vital for detailed inspections. We’ll explore how these tethers improve the performance of VersaTrax pipe inspection crawlers, making them an essential tool for infrastructure management.

Ask an ExpertBenefits

- Fiber optic tethers provide high-resolution video, real-time data transfer, improved signal integrity, enhanced data capacity, and reduced signal loss, making them indispensable in modern underground pipe inspections.

Fiber optic tethers facilitate the real-time transfer of data between the robotic crawler and the ICON™ control station. This immediate transmission allows inspectors to view the crawler’s video feed and diagnostic data as it is collected, enhancing decision-making and enabling prompt identification of issues. This capability is essential for planning repairs or maintenance efficiently.

Improved Signal Integrity

Unlike traditional electrical cables, fiber optic cables are immune to electromagnetic interference and signal degradation over long distances. This ensures that data transmitted from the crawler remains clear and accurate, even when inspecting long or complex pipe networks. The enhanced signal provided by fiber optics ensures that inspectors receive reliable data, which is essential for making informed decisions about the condition of the pipes.

Reduced Signal Loss

Signal loss is a common issue with traditional cables, especially over long distances. Fiber optic tethers experience minimal signal loss, ensuring that the data sent from the VersaTrax crawler to the ICON control station remains strong and accurate. This reduction in signal loss is particularly important for long pipeline inspections, where maintaining data quality is critical for accurate assessments.

High-Resolution Video Transmission

One of the most significant advantages of fiber optic tethers is their ability to transmit high-resolution video feeds with minimal latency. The substantial bandwidth of fiber optics enables the transmission of detailed, high-definition images and videos from the crawler’s onboard camera. This enhanced visual clarity enables inspectors to detect fine details, such as small cracks, corrosion, or other anomalies within the pipe, which might be missed with lower-quality video feeds.

Enhanced Data Capacity

Fiber optic tethers offer significantly higher data transmission capacity compared to copper cables. This increased capacity supports the use of advanced sensors and additional data collection tools on the inspection crawler. For example, crawlers equipped with NDT acquisition instruments, ultrasonic sensors, sonar, or laser profiling equipment can transmit large volumes of data without compromising the quality of the visual feed. This comprehensive data collection provides a more thorough assessment of the pipe’s condition.

Check out this eBook on Robotics for NDT Data Collection.

In conclusion, the use of fiber optic tethers has revolutionized underground pipe inspections by significantly enhancing the capabilities of Eddyfi Technologies’ inspection crawlers. The high-resolution video transmission, real-time data transfer, and improved signal integrity provided by these tethers allow for more detailed and accurate assessments of underground pipelines. By integrating fiber optics, VersaTrax inspection crawlers can provide a clearer, more comprehensive view of pipe conditions, leading to more effective maintenance and repair strategies. As technology continues to advance, fiber optic tethers will undoubtedly play an increasingly important role in ensuring the integrity and reliability of our critical underground infrastructure.

Contact our robotics experts to discuss how the applicability of our remotely operated inspection crawlers can take your non-destructive testing to the next level.

Author: Jeff Abt