Our crawler systems are ideally suited to the challenges of inspecting municipal pipelines, and they offer some capabilities that you don’t find elsewhere.

Details

Most of us never think about it, but almost every modern city, town and village has a network of sewer, storm drain and water pipe running right under our feet. Infiltration of tree roots, seismic activity, heavy road traffic and regular usage all cause damage that these waterline pipe systems must endure; regular inspection and maintenance programs are critical to ensure ongoing effectiveness. Eddyfi Technologies' robotic crawlers can be part of the solution.

Our crawler systems are ideally suited to the challenges of inspecting municipal pipelines, and they offer some capabilities that you just don’t find elsewhere. Not only can our systems go further —up to 2 kilometres/1.2 miles in a single run— but they also come with options for NDT sensors, remote grippers, and more. Designed to operate in some of the most confined and inhospitable environments, Multi-Mission Modular (IM3™) technology can perform in-service inspections, often requiring no prior cleaning of pipelines. Some of our systems can even being utilized inside of live, pressurized water mains.

For strategic, risk-based municipal asset management practices, our remote visual inspection systems can reliably report on:

- Cracks, fractures, holes and pipe defects

- Broken, collapsed and sagging pipes

- Separated pipe joints

- Leaks and infiltration

- Root penetration, blockages and other obstacles

With Eddyfi Technologies' innovative, modular technology and versatile design capability, integrating sensors and non-destructive testing tools is a painless process. With proven options and accessories like lasers for feature measurement, ultrasonic testing probes for thickness readings, and manipulators for remote handling and retrieval operations, many challenges can be resolved right out of the box. But, when something more specialized is required, we have the personnel and the experience to incorporate almost any tool or sensor package.

Based on our decades of problem-solving, project development and partnership across the municipal water and sewer industry, Eddyfi Technologies' experts have designed, engineered and adapted numerous products and specialty systems to help get the job done. Some are purpose-built for the challenges and requirements of the municipal water and sewer sector. Others are the workhorses you count on every day, to do what people can’t manage, or shouldn’t attempt.

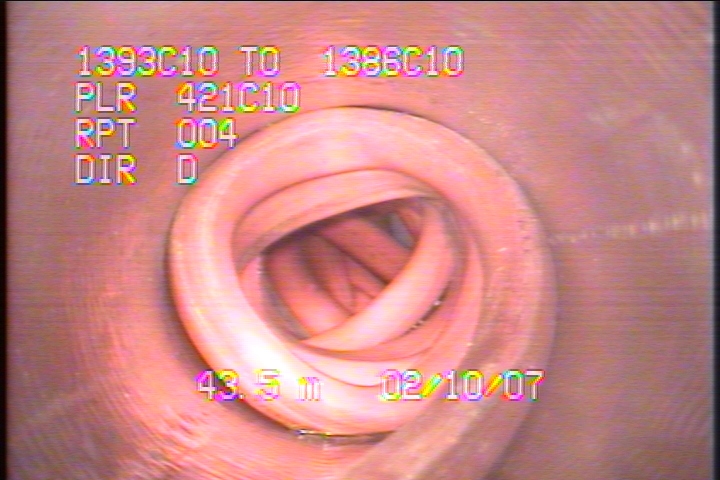

Plug-and-play camera and crawler systems require minimal operational training, offer easy data analysis, and usually need no pipe preparation to navigate in the often dirty, silty conditions and obstacle prone paths. Our IM3™ technology can regularly be found inspecting process pipes, sewer lines and storm drains.

Consider our robotic solutions as a necessary component for structural integrity condition assessments in an era of infrastructure replacement. It's up to our cities and municipalities to collect reliable data to ensure that investments are made in a timely matter to minimize future repairs and rehabilitation expenditures and effectively maintain civil assets. Eddyfi Technologies offers the Beyond Current solution. Contact our friendly and helpful staff to assist with your remote inspection needs today.

Learn more

Learn more

IM3™ Technology in the Municipal Water & Sewer Industry

- Sewer line inspection with Spectrum 90™ camera

- Water intake line inspection with 300™ long range crawler

- Penstock inspection with Versatrax 150™ crawler

- Freshwater pipeline inspection with Versatrax 150™

- Underwater sewer pipe inspection with Versatrax 300™ crawler

- Irrigation system inspection by US Army with Versatrax™ crawlers | View here