It’s estimated that by 2025 as much as 75% of non-destructive testing will be performed remotely. We’re already seeing the steady increase in the introduction of robotics designed to collect data from scenarios where direct human intervention is not possible nor safe. With Eddyfi Technologies’ synergistic product portfolio, we’re able to leverage the most advanced NDT technologies in the world with in-house Inuktun robotic platforms ready to go the distance. But when and where should this be applied?

We’ve addressed exactly that in an exclusive eBook demonstrating NDT sensor integration with Eddyfi Technologies’ inspection robots. Here we introduce the RAMP Index as a measurement framework for ensuring positive NDT outcomes. To be Repeatable, and therefore Actionable, measurements must be Meaningful in order to be Preventative. After all, doesn’t NDT boil down to the data? We explore data-driven optimization with real life examples. We offer an excerpt here.

“REPEATABLE INSPECTION

While rope access will always be possible in the splash zone areas, our adaptable robotic solutions are demonstrating their value when it comes to safety, economy and ability to operate continuously. Remote Visual Inspection (RVI) performed in the volatile offshore environment affords objective data through high definition video footage, with ICON™ software identifying vehicle location and the option to tag areas of interest for comparative analysis and audit purposes.

Robotic crawlers like the Inuktun MiniMag™ solve the challenges faced with moving sensors and tools in offshore environments and have been designed with harsh settings in mind. Our Alternating Current Field Measurement (ACFM®) inspection technology is robotically deployed and serves as a method to semi-autonomously detect cracks in a range of subsea geometries including fillet, circumferential and full penetration welds in pipes and plates. This OnSpec Custom Solution is used to inspect many shallow water structures with the ACFM technique; the sensitivity is such that surface breaking defects of 10mm long by 1mm deep can be detected easily when and for non-conductive coatings up to 2mm thick (the usual reporting threshold being 20mm long by 2mm deep). It provides the critical data owners and operators need to fully understand remaining useful life conditions and proactively prepare maintenance or repair activities—year over year, with remotely operated inspections on repeat.

RAMPING UP: While this OnSpec Custom Solution is primarily used in the offshore energy sector for onboard NDT, the options are seemingly endless with different configurations mobilized by Inuktun robotic crawlers. We’re just getting started.

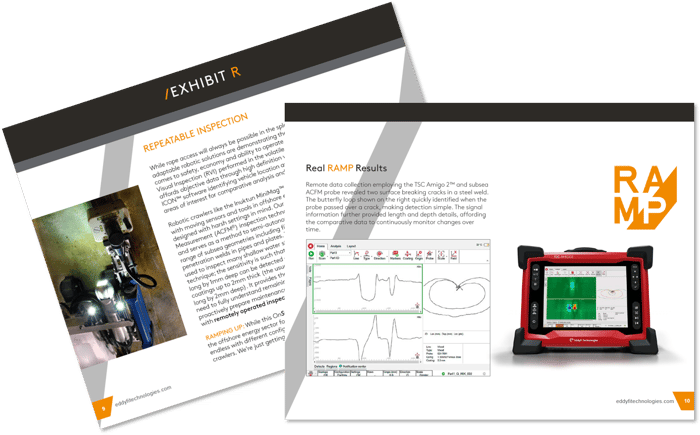

Real RAMP Results

Remote data collection employing the TSC Amigo 2™ and subsea ACFM probe revealed two surface breaking cracks in a steel weld. The butterfly loop shown on the right quickly identified when the probe passed over a crack, making detection simple. The signal information further provided length and depth details, affording the comparative data to continuously monitor changes over time.”

Get your free copy of this eBook online here.

Let’s RAMP up together! Contact our experts to discuss how robotics can enhance your inspection operations today.