Eddyfi Launches a New Generation of Sharck Probes

From: Wednesday, April 5, 2017

An evolution making it even easier and faster to detect and size cracks in carbon steel welds.

As a world leader in electromagnetic inspection technologies, Eddyfi is proud to announce a new generation of field-proven Sharck™ probes, which are dedicated to carbon steel crack assessment.

The tangential eddy current array (TECA™) probes were redesigned to incorporate user-requested features and improvements inspired from lessons learned in the field. For example, the probe’s active surface is now more resistant to wear and tear (up to 10 times), new control buttons on the housing facilitate one-man inspection, and the ergonomics were improved.

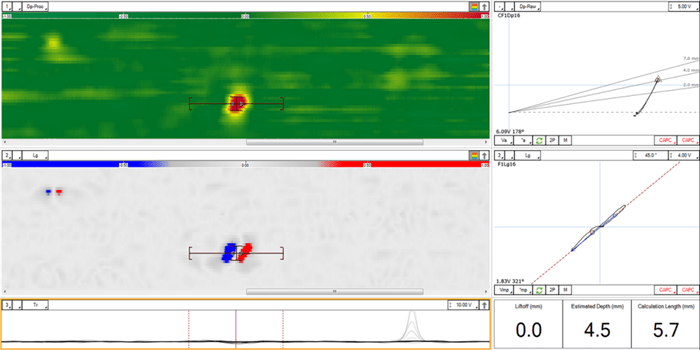

Beyond these design improvements, all Sharck probe setups were optimized to simplify data visualization during scans and analysis. Dedicated software tools also make it easier and faster to analyze data:

- Fewer views and C-scans are necessary to fully assess and sentence a weld quickly.

- Sizing overlays and cursors automatically provide the length and depth of detected cracks.

- Data analysts are prompted to confirm or adjust the automated measurements from the system when a defect is discovered.

The result is a compelling data display for quick and intuitive analysis.

“The patent-pending Sharck probes are designed around the user’s needs,” said Angélique Raude, surface inspection product manager at Eddyfi. “They replace conventional inspection methods such as PT and MT in a wide range of applications. Through paint and coatings and with minimal surface preparation, they are the fastest, simplest, and most reliable to detect, size, and assess the depth of cracks in vessels, tanks, bridges, and other assets.”

The Sharck probe family is composed of the following probe models:

- Butt weld

- Fillet weld

- Straight pencil

- Right-angle pencil

About Eddyfi Technologies

Eddyfi Technologies is a label designed to maximize the potential of multiple advanced and niche NDT inspection technology brands. With its two centers of excellence in Québec (Canada) and Swansea (UK), Eddyfi Technologies focuses on offering high-performance NDT solutions for the inspection of critical components and assets through two strong, complementary brands: Eddyfi and Silverwing. The company has more than 200 employees, six offices around the globe all staffed with NDT experts, and serves customers in more than 65 countries in such major industries as nuclear, power generation, oil & gas, and aerospace.