There has been great demand for the inspection of Glass Fiber Reinforced Plastic (GFRP or GRP) and Carbon Fiber Reinforced Plastic (CFRP or CRP) materials. Compared to the metal components used in the oil, gas and petrochemical industry, these composites offer great advantages. In areas where high corrosion is suspected —from offshore platforms to onshore process plants— GRP and CRP have shown a great difference in terms of strength-to-weight ratio, service life, ease of installation, and low maintenance. These benefits make composite material pipes the preferred choice.

At the same time, there is uncertainty in quality assurance due to a lack of common inspection practices. This article identifies best practices to help alleviate this uncertainty and is based on existing knowledge related to glass and carbon fiber reinforced plastic materials.

As with all other materials, flaws in GFRP or CFRP can be generated during different stages of the manufacturing process from raw materials to finished components, during installation and commissioning, or during operation. The purpose for inspection prior to commissioning is to identify deviations from specifications or functional requirements as early as possible and form a basis for corrective actions for comparison with future inspections. During service, the role of inspection is to assure high levels of safety and regularity during operation, form a basis for maintenance evaluation and planning (including "fitness-for-purpose"), contribute to the improvement of current and future design, and compare the new inspection results with the initial results during manufacturing stages.

Current Strategies, Strengths and Limitations

Most composite material piping and tank applications have historically been inspected using a combination of visual and pressure testing. This approach has generally functioned quite well, and it is anticipated that these two methods will remain center for most inspections. Some difficulties with the historical approach have been noted with GRP or CRP used in production facilities. Over-reliance on system pressure testing has occasionally been a contributing factor to inadequate quality control of the system during various stages of manufacturing, receiving control, and installation. Visual inspection criteria has been overly subjective, i.e., photographic standards for piping applications are not readily available. Pressure testing often occurs at a later stage in project construction, making any necessary repairs difficult due to limited access and costly. Occasionally the cost of pressure testing, including isolating the GFRP or CFRP systems, is more than the system itself.

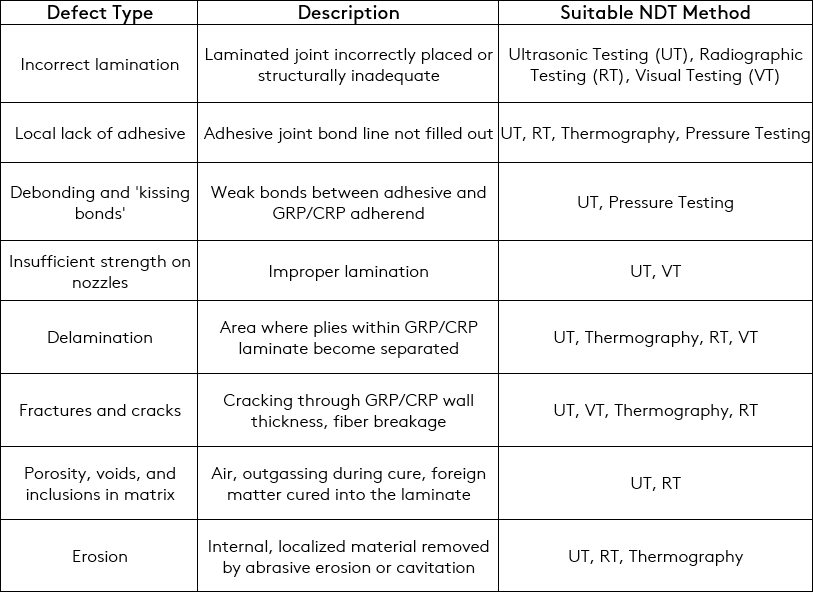

Defect Types and What to Look for

Usually the defects that would be detected with such inspections are either in the materials itself or in the adhesive bonded joints. For carbon or glass fiber reinforced plastic piping, the process is less complex and more automated leading to less defects in the materials. Fittings are more complex and not typically automated which might lead to more suspicion of defects.

Ultrasonic Inspection of GRP/CRP Materials

When performing ultrasonic inspection, follow the same inspection strategy for corrosion monitoring. It’s important to have sufficiently cleaned the area under assessment to help the movement of transducers for maximum ultrasonic penetration.

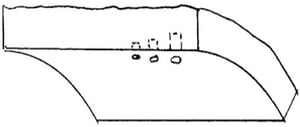

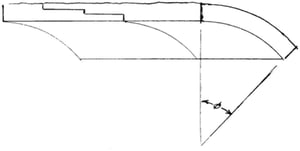

Calibration standards typically correlate with the respective sizes of the tanks or pipes under examination. The calibration standard for adhesive bonded joints should be produced using adherents (pipe segments or tank laminates) with matching stair-step patterns machined into the surfaces.

Controlled voids, or areas lacking adhesive, may form from incomplete coating with adhesive or removable strips of Teflon, for example. Both exterior, inner, and machined surfaces should be representative of the surface roughness during fabrication and shaving of adherents prior to adhesive bonding.

Here is an example of a calibration block that may be used for inspection of glass or carbon reinforced plastic pipe bonded material.

What to Expect from an Ultrasonic Inspection

- Size and position of any observed defects

- Identification and location of the joint inspected

- Name, type, and serial number of the instrument used

- Probe type and operational frequency

- Identification of the calibration standard used

- Identification of inspection template used

- Name and certification level of operator

- Date and time of the inspection

What’s Needed for Inspection

Eddyfi Technologies offers a wide range of products that can be deployed for such inspection and both the M2M Gekko® and Mantis™ can be used for advanced Phased Array UT (PAUT). These instruments make use of high-end ultrasonic methodology. For more information related to PAUT, visit here.

When performing PAUT inspections, one of the crucial steps is selecting the right type of transducers that will generate enough energy to penetrate the composite material.

The Beyond Current Solution

The PAUT instruments offered by Eddyfi Technologies come with transducers and scanner handpicked for an out-of-the-box and ready-to-inspect solution.

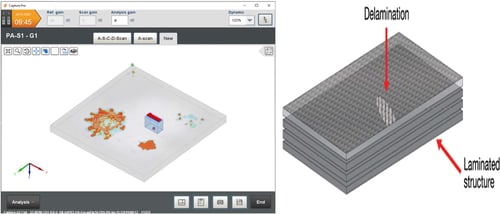

Setup for your GRP or CRP ultrasonic inspection takes several parameters into account. This includes specimen geometry and material parameters. Focal laws need to be powerful enough to recreate the ultrasonic behavior in such materials. Capture™ software embedded on the Gekko and Mantis portable PAUT tools produces the most desired focal best suited for inspection materials in complex geometry.

This robust software comes packed with state-of-the-art analysis tools that help not only detect but also provide the best view of the defects in a 3D format. The instruments provide a great PRF range to help operators choose the best PRF that keeps the inspection cycle time low.

Assessing carbon and glass reinforced plastic materials using phased arrays not only helps detect defects but also do so very quickly, meaning inspections offer increased productivity. We invite you to contact our NDT experts to discuss how our phased array UT instruments can help optimize your composite pipeline and tank assessments today and stay Beyond Current.

.jpg)