Pulsed Eddy Current (PEC)

Pulsed Eddy Current (PEC) is an advanced electromagnetic inspection technology used in detecting flaws and corrosion in ferrous materials typically hidden under layers of coating, fireproofing, or insulation.

Details

How it works

Pulsed Eddy Current (PEC) is an electromagnetic inspection technique used to detect wall loss on ferromagnetic structures such as carbon steel and cast iron. It provides a relative volumetric measurement converted into an averaged thickness measurement based on the calibration area.

To generate and capture PEC, first, a magnetic field is created by an electrical current in the coils of the probe. It penetrates through the cladding, any non-conductive insulation (concrete, silicate, insulation with weather jacket or marine growth) and stabilizes in the component thickness. Then, the emission is cut off. This abrupt change induces eddy currents that will be captured by the probe. The Eddyfi Lyft® instrument measures the decay rate and an advanced signal processing algorithm translates the electromagnetic signal into an average thickness reading over the footprint of the probe.

Benefits

Pulsed eddy current is one of the most versatile NDT techniques on the market. It can measure the remaining thickness of a component with a liftoff of any non-ferromagnetic form:

- Insulation with weather jacket (aluminum, stainless steel, galvanized steel)

- Concrete/Silicate

- Composite wrap/Polymer coating

- Marine growth

Lyft is a state-of-the-art high-performance PEC system offering an easy to deploy solution. It is quick and simple to setup. There is no surface preparation needed including coating/insulation removal. The inspection can be performed while the asset is in-service even if the temperature in contact is up to 120° C (250° F).

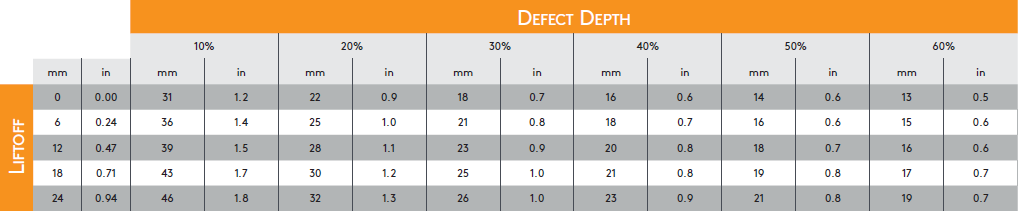

Choosing the right probe

Choosing the right probe is a key of success for a great inspection. Indeed, every probe has a specific footprint at zero liftoff. The footprint is the area with the most sensitive detection capabilities. As PEC is a volumetric measurement, Lyft can detect an indication that is a minimum volume ratio of 15% of the footprint. The footprint is calculated easily:

For help choosing the right probe, refer to the probe selection table.

Also, to easily tell the smallest detectable indication, we provide the minimum detectable defect (MDD) in the sale table.

Standard applications

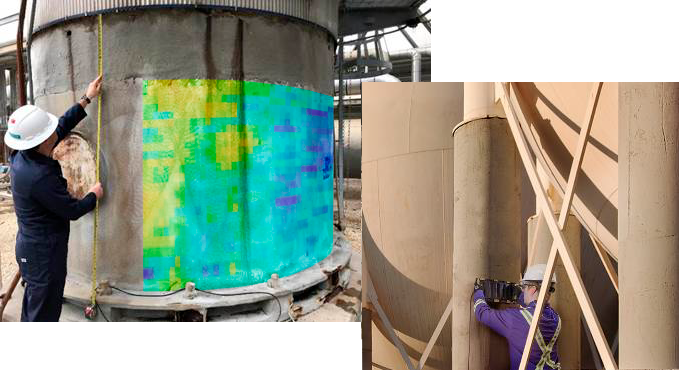

Corrosion Under Insulation (CUI) and Fireproofing (CUF)

The PECA-6CH probe is a high-productivity probe for CUI on insulated pipes as it can scan dynamically with an 18in (457mm) coverage. It can scan from 6in (150mm) OD to flat surfaces, and it can inspect through 4in (100mm) of insulation. The same probe can be used to inspect through thick concrete fireproofing to assess the condition of sphere legs and vessel skirts.

Scab and blister assessment

The PECA-HR probe has achieved the smallest footprint ever done in pulsed eddy current. It gives the best estimation of remaining ligament under scab corrosion. It provides top-quality data with a high productivity rate. This technique is a safe assessment of the remaining wall thickness.

Flow-Accelerated Corrosion (FAC)

You can scan an isolated elbow to assess FAC without removing the insulation. This is cost effective when you are regularly monitoring the elbows of a specific system. To perform this kind of inspection, the suggested probe remains the single-element probes

Specialized applications

As PEC is versatile, Eddyfi Technologies provides some dedicated solutions for specialized applications:

- Tank floor annular ring

- Underwater inspection

- Splash zone inspection

- Galvanized steel cladding

- Ship deck inspection

Limitations

- Screening tool; relative measurement

- No discriminate near-side/far-side defects

- Impossible to detect small pitting

- Undersizing of flaws smaller than the averaging area of the probe

- Edge effect near metallic surfaces