Eddy Current Array (ECA)

ECA is the supercharged version of Eddy Current Testing (ECT).

Details

How it Works

An eddy current array, in its simplest form, is a series of single elements arranged in a row, allowing users to cover a larger area in a single pass than conventional, single-coil probes (i.e., pencil probes using (ECT)). However, this could lead to suboptimal results. That’s why ECA probes use multiplexing.

Multiplexing involves activating and deactivating coils in specific sequences to leverage the probe’s width. Multiplexing also minimizes the interference between coils in close proximity (mutual inductance) and maximizes the resolution of the probe.

ECA probes effectively eliminate the raster scanning necessary when using ECT pencil probes. This has a significant impact on inspection speeds.

Ask an ExpertBenefits

ECA is a major improvement over single-element (ECT) because:

- Faster inspections

- Wider coverage

- Less operator dependent — eddy current array probes yield more consistent results compared to manual raster scans

- Better detection capabilities

- Easier analysis because of simpler scan patterns

- Improved positioning and sizing because of encoded data

- Eddy current array probes can easily be designed to be flexible or shaped to specifications, making hard-to-reach areas easier to inspect

Tubing Applications

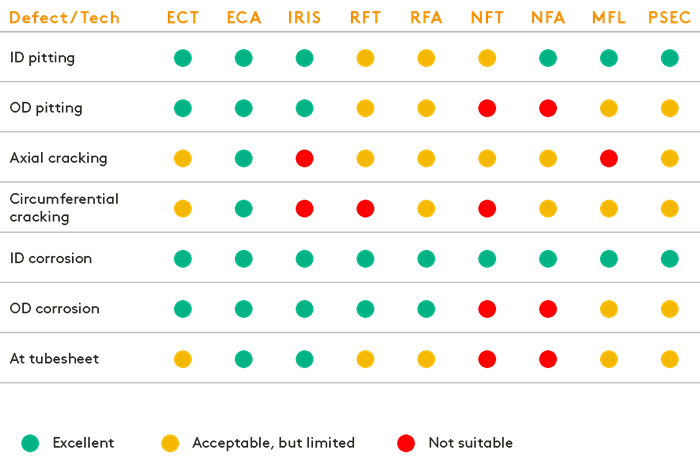

Detection Capabilities According to Defect Type in Tubing

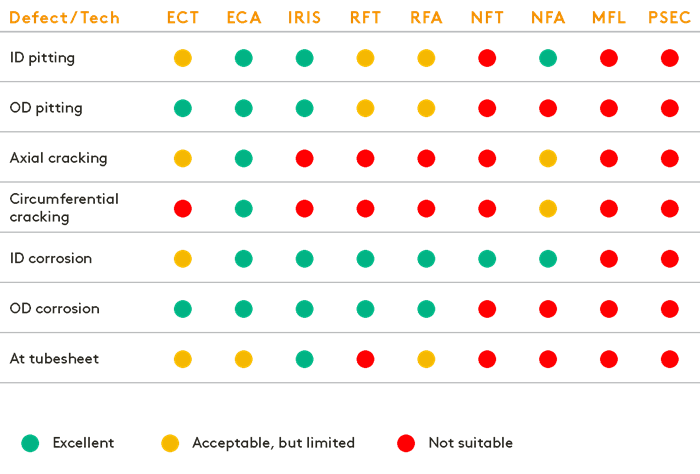

Sizing Capabilities According to Defect Type in Tubing

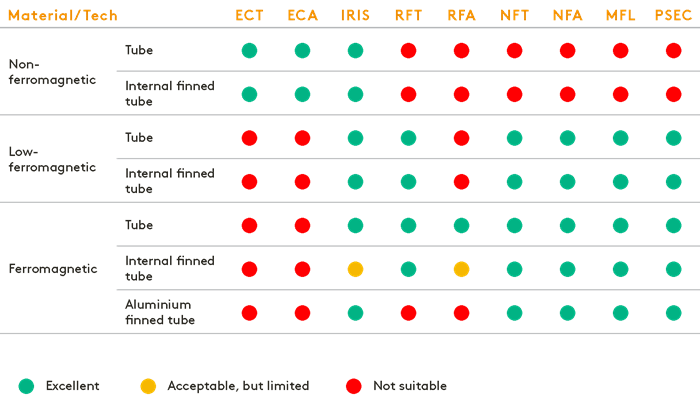

Suitability According to Tubing Material

Surface Applications

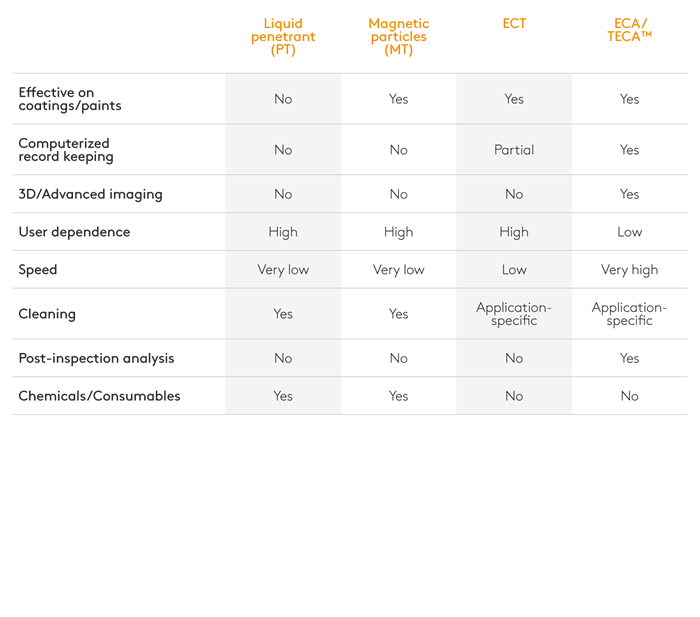

When it comes to surface applications, the performance of any given inspection technique depends greatly on the specific conditions — mostly the types of materials and defects, but also surface conditions, cleanliness, etc. However, in most situations, the following are true:

Learn more