2015

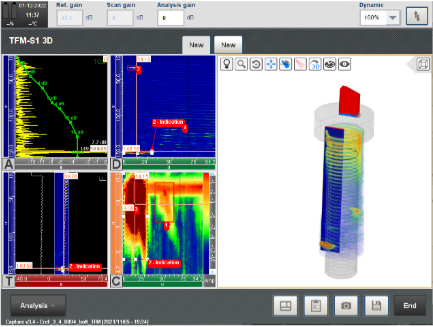

Real-time TFM

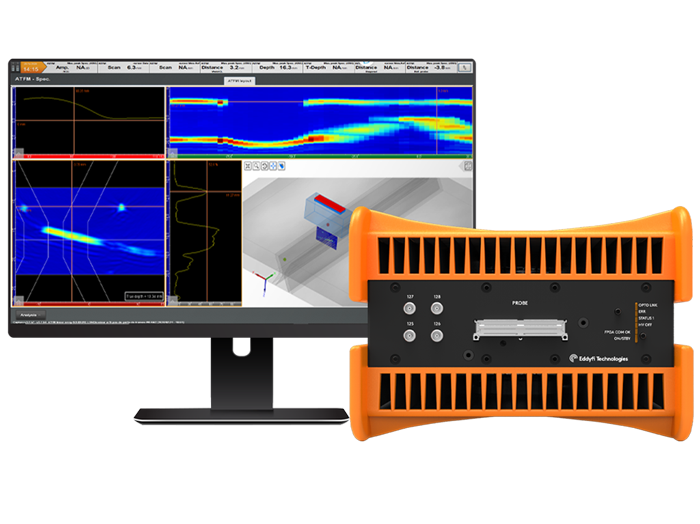

Benefiting from a strong partnership with the CEA (France), Eddyfi Technologies -historically M2M- launched the first PAUT portable unit called GEKKO, reinventing high-definition portable ultrasonic testing with the groundbreaking TFM (Total Focusing Method) technique.

Guided setup creation

A streamlined step-by-step software interface has been developed from day 1 to help users to follow and respect inspection procedures "good practices" and provide advanced ultrasonic technology to all level operators.

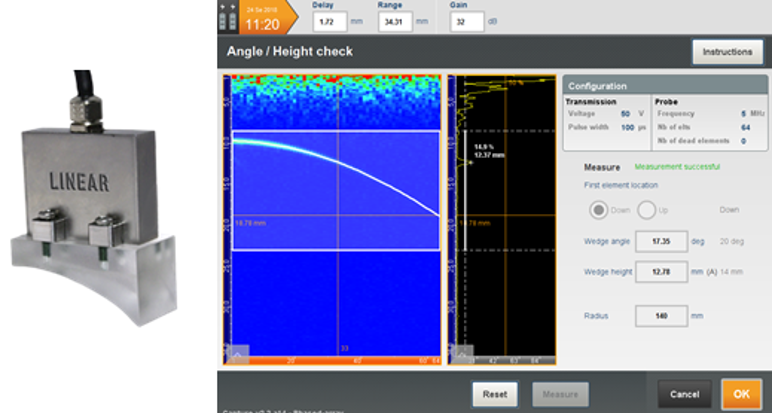

3-click calibration wizards

To simplify user’s daily operations, innovative calibration wizards have been designed to measure the essential UT parameters quickly and accurately, from wedge delay to time-corrected gain (TCG).

2016

Real time adaptive TFM

A unique real-time adaptive TFM solution embedded in a portable instrument developped in collaboration with the CEA, for wavy and evolutive surface components.

Advanced inspections

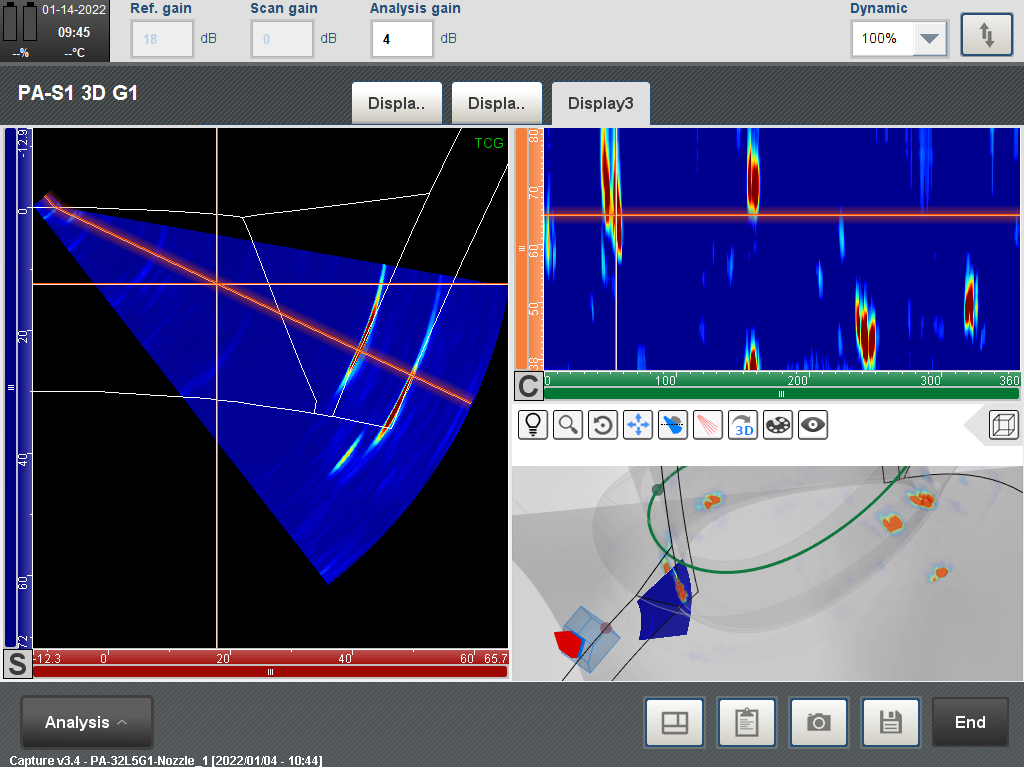

Nozzle: nozzle inspection made easy with the power of augmented reality, compatible with innovative 3-axis encoded scanners.

Fillet weld: a dedicated fillet weld configuration for T&Y joints, allowing scan plan creation directly on the equipment for complete weld coverage and to help diagnosis.

3-Axis Rotating scanner: a paint-brush data acquisition made possible with the unique 3-axis scanner control.

Custom probe configuration

Thanks to its full 64-element parallel architecture, the GEKKO has been the perfect portable equipment for thick component inspections. In addition to conventional UT transducers, linear, matrix, dual linear (DLA) and dual matrix arrays (DMA) are all managed allowing the use of any kind of probe available on the market.

2017

TFM toolbox

FMC (Full Matrix Capture) export: R&D tool for offline analysis, it is used to save FMC data for further post-processing of the TFM image with different modes of construction or resolution.

TCG calibration: the recognize advanced TCG calibration wizard made compatible with TFM inspections.

TFM 2D Mapping: a full set of views and tools available with TFM to perform inspections with up to 3- axis.

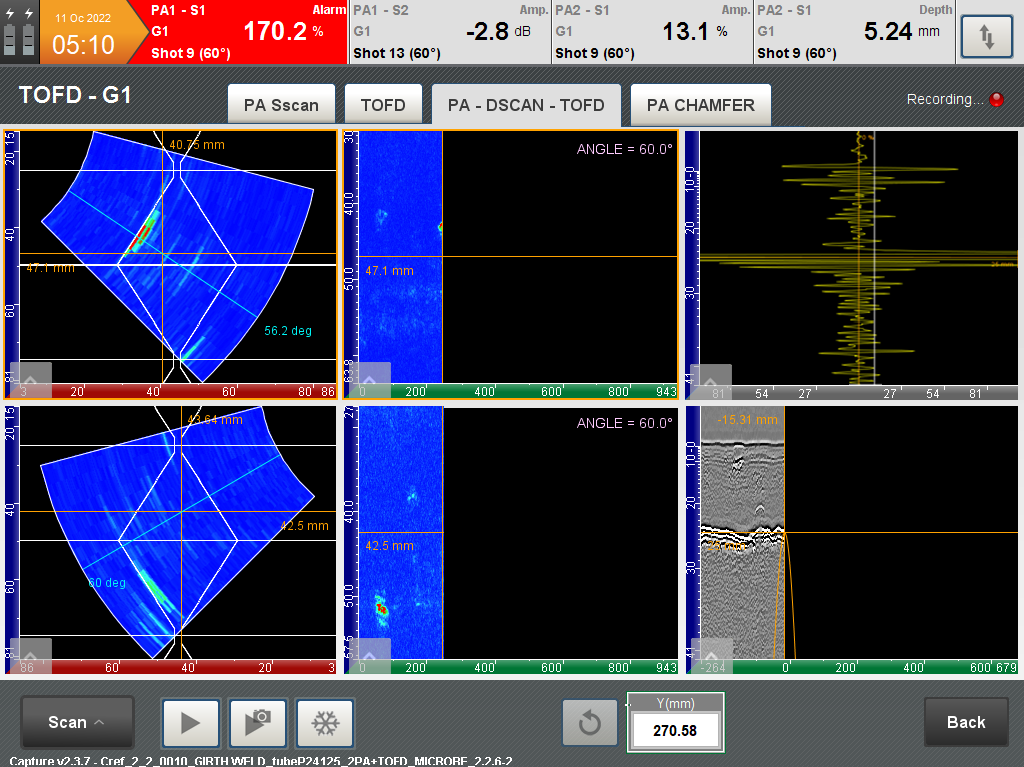

ToFD analysis tools

TOFD (Time-Of-Flight Diffraction) has been part of the Capture arsenal since day one. Software updates have provided all the required analysis tools : wedge delay & PCS calibration, hyperbolic cursors, lateral wave straightening and removal. It can be used as a single technique or combined with PA groups to realize advanced weld inspections.

Capture drives Mantis

The name Capture was born with the arrival of MANTISTM, the lightweight 16:64PR portable unit which includes real-time TFM. For this occasion, corrosion tools were developped to make corrosion mapping inspections easier and more efficient while providing multi-group configuration for thin weld inspections.

2018

Sparse TFM

To speed up TFM acquisition, various tools and algorithm optimizations have been developed providing a significant scanning speed increase.

COD wedge calibration

Capture offered a unique 3-click wedge delay calibration for COD (Circumferential Outside Diameter) wedges, which simplifies a lot calibration for longitudinal weld inspection

Enhanced data quality

Several optimizations have been brought to guarantee the quality of the data acquired, whether through data frame loss information, or smart "auto" UT setup for optimum data compression while maintaining optimal signal resolution. Enveloppe and smoothing features also help to enhance the data quality.

2019

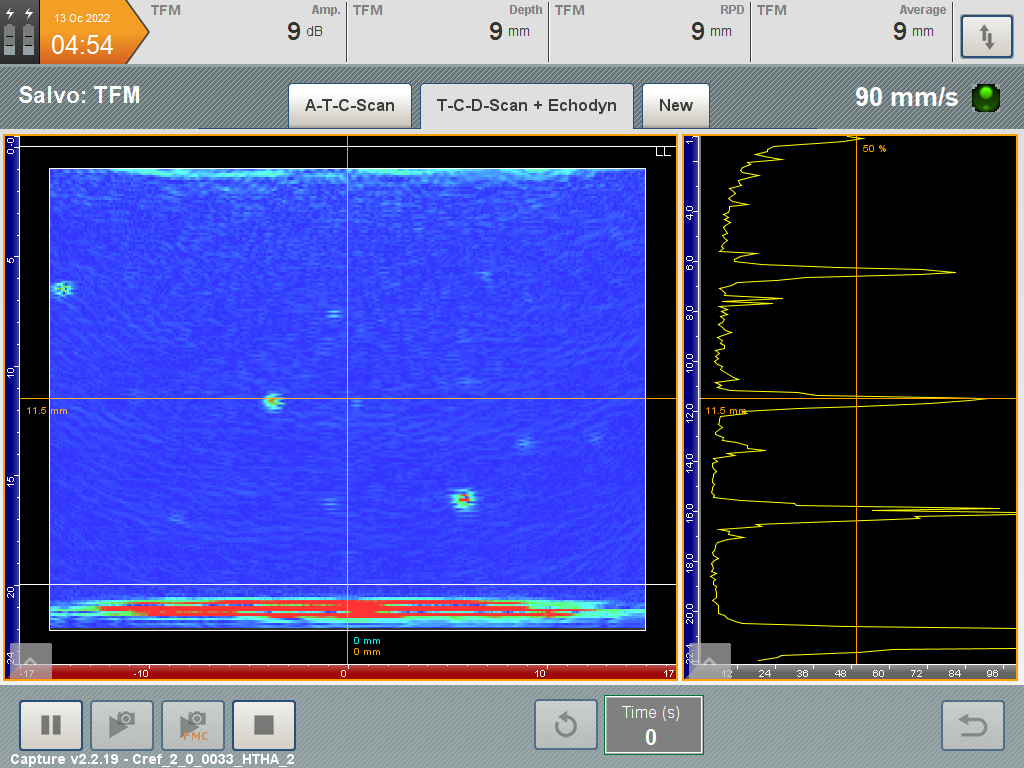

TFM high resolution

Just like TFM scan speed, improving TFM resolution has been a continuous effort of Eddyfi Technologies. Having more pixels allows the inspection of thicker components with larger TFM zones while keeping an optimal display and sensitivity.

Advanced focal law calculation

Aside from TFM innovation, continuous improvement have been brought to PAUT technology to offer all recognized techniques and simplify operator's focal law setup. Typically compound mode, projection focusing options, half step linear scan definition and multi-skip ray tracing have been implemented.

Streamlined data analysis

Many ergonomics and features related to analysis have been added to simplify and speed up the reporting process. Editable layouts, enhanced readings banner, indication table, or 3-cursor management and defect auto-sizing are a few examples of improvements realized.

2020

PWI/TFM transmission mode

The innovative PWI (plane wave imagining) TFM mode provides an increase in productivity while keeping the optimum spatial resolution offered by TFM. Moreover, PWI provides a better data quality on attenuative components thanks to its greater penetration power.

Amplitude fidelity check

Standards such as ASME and ISO introduced a specific "TFM grid verification" calibration to ensure that the grid resolution is good enough to maintain maximum peak amplitude. Capture is the only system to provide an experimental amplitude fidelity algorithm

PRO version for advanced analysis

Advanced PAUT analysis has never been more comprehensive and powerful with Capture PRO. 3D data projection allows to highlight in the 3D representation of the component the true position of indications and help to build the inspection report. Capture PRO offers automatic sizing of defects based on a decibel drop method. Both floating gates and corrosion autosizing boxes have been developed to improve significantly the C-scan display and save time to identify and size corroded areas.

2021

TFM multi-group

Capture has brought multi-modes and multi-probes TFM capabilities together with up to four groups. Multi-group is particularly useful for butt weld inspection as welds must be inspected from both sides. When combined with TCG calibration and PWI, this allows for code compliant high scanning speed inspections.

Embbeded scan plan

Another major development was the advanced scan plan for PAUT, TFM, TOFD and conventional UT techniques. It includes multi-skip ray tracing, near field information, bevel interface angles, adjustable beam spread - all these features are displayed live during setup configuration.

True CAD import

Complex components can be challenging to inspect due to the difficulty in finding a proper scan plan. Undesirable echoes coming from various places in the geometry make analysis complicated and tedious. Capture offers the ability to import true CAD files and superimpose the ultrasonic data, PAUT and TFM, which helps operators position precisely any indications and distinguish between geometry echoes and echoes coming from defects.

Cloud version management

With the easy connectivity solution for both portable and desktop units, we have understandably offered a remote version update in Capture. A complete version manager allows the access to the release notes or to boot on a previous version.

2022

Industrial TFM capabilities

Capture introduced new reconstruction modes (5L, 5T and LLT) compatible with FMC/TFM and PWI, and the resolution and scanning speed were again improved for all types of TFM applications. The true CAD import was also extended to TFM applications offering high resolution imaging to complex component inspections. Associated to the multi-probe/group TFM capabilities and code compliant calibration wizards, Capture provides the fastest and most complete TFM solution on a portable instrument.

Enhanced nozzle inspection

Capture software adds the ability to define weld overlays for straight nozzle and node configurations. Compatible with PAUT and TFM inspections, operators have a real-time display of their welds providing huge improvement in terms of probe positioning and defect characterization.

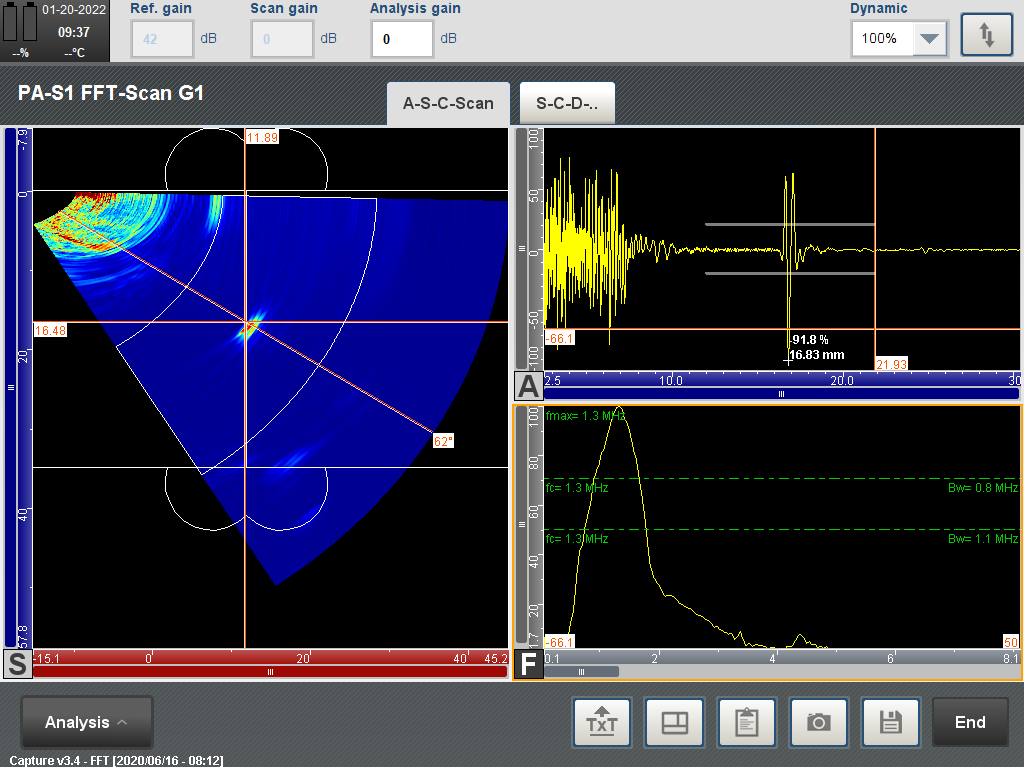

Inspection ergonomics

View Scrolling and full UT parameters edition during inspection improve productivity, improve user's confidence and ergonomics. Optimized imagery performance and FFT view to easily check the actual frequency of any signal also provide operators with more tools to perform their analysis

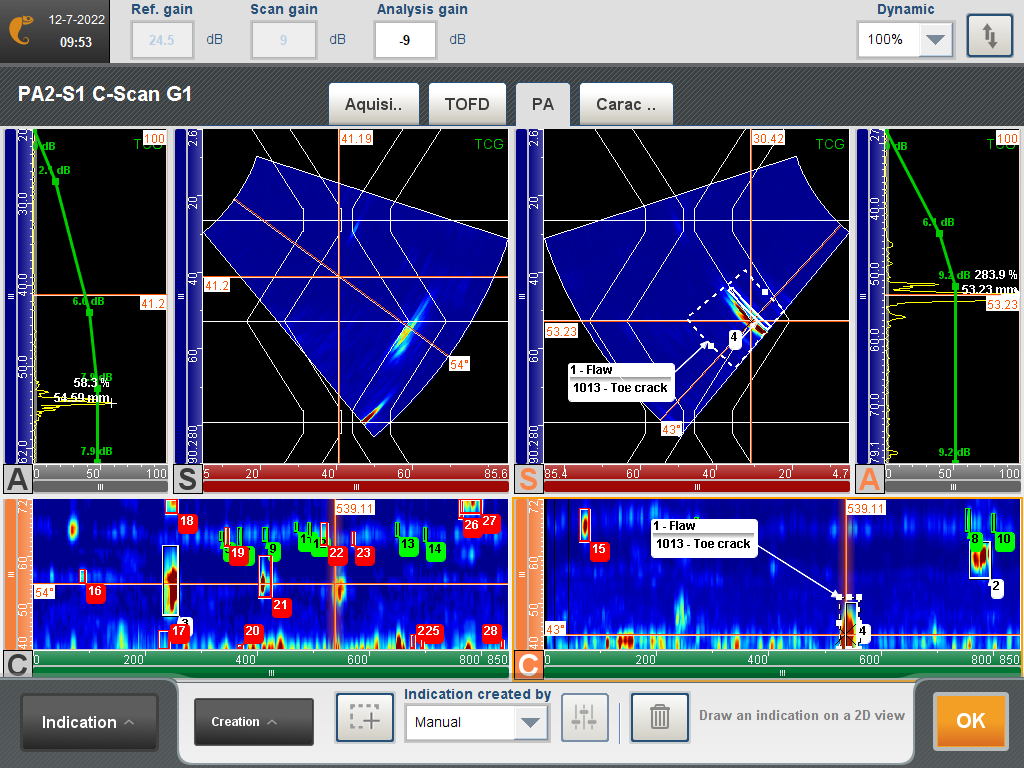

Assisted analysis for butt weld

A dedicated assisted analysis module has been developed to automatically extract defects from a PAUT butt weld inspection and automatically fill a table of indications with position and sizing information. This feature improves the analysis productivity and repeatability.

Capture drives Panther

Capture family keeps growing with Panther compatibility for both unit control and analysis. It provides users the same streamlined interface and smart features as Gekko/Mantis users with the additional power of Panther.