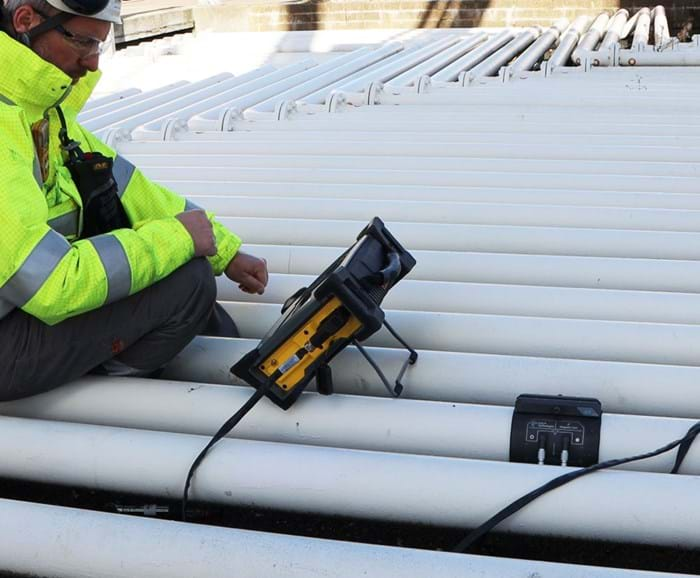

SonyksTM is a major leap in guided wave equipment. Eddyfi Technologies has redefined guided wave ultrasonic testing with the Sonyks setting new benchmarks for data quality, versatility, ease of use, and deployment. Designed by the pioneers of Guided Wave Testing (GWT), the state-of-the-art system comes with a large high-quality touchscreen, ultra-fast electronics for rapid data acquisition, and on-the-spot data analysis capabilities for accurate reporting. Sonyks has reinvented guided waves, making the technology simpler and more accessible for the industry.

Details

Benefits

Sonyks offers an unprecedented ability to inspect more piping applications, including flange-to-flange piping, in the most cost and time-efficient manner.

The instrument is also compatible with typical transducer rings found on the market. Reuse your own rings and make the most of your past investment in guided waves. Couple your existing collars to a new-generation instrument with best-in-class electronics and give a second life to your inspection programs.

- First Guided Wave instrument with full onboard data analysis

- Unmatched SNR for longer inspection runs

- Easy to interpret data making the technology more accessible

- Compatible with other manufacturer transducer rings

- Collect all RAW data in one scan for accurate and auditable results

- Streamlined workflow, increasing efficiency and inspection capabilities

- Transducer rings suitable for pipes ranging 1.5 in to 72 in

- Internal compressor for inflation of collars

Want to see Sonyks in action? Book a remote demo!

Sonyks System

- First Guided Wave instrument with onboard screen for interpretation

- Revolutionary data collection procedure

- Onboard pump and full diagnostics

- Compatible with most commercial Piezo GWT equipment

- The lightest tool on the market

- Rapid deployment Magneto-tool

- Single connection Piezo-tooling

Sonyks Instrument

- Field proven Eddyfi platform

- Premium-quality 26.4 cm (10.4 in) LED touchscreen display

- Quick access hard button

- Hot-swappable batteries

- Integrated pump for ring inflation

- Onboard testing and diagnostics for faster setup times

Piezo Collars

- Unique ring spacing gives the broadest frequency range of Inspection on the market

- High definition not just included but standard

- Single connection between instrument and the tool

- Extremely flexible for easy packing and shipping

- Lightest tool on the market

Magneto Collars

- Revolutionary segmented Magneto-tooling for small pipes ranging from 1.5, 2, 3, and 4 inch

- Step change improvement in signal-to-noise ratio

- Tailored frequency options for high attenuation or high-resolution applications

- Greater portability, ideal for flange-to-flange pipe sections

- Low profile clearance

- Quick connector with torque setting to ensure correct pressure

Simplified & streamlined workflow for top efficiency

Thanks to a project-based inspection setup, time spent at a location can be reduced by 33%. This combined with a new multilocation reporting feature generates significant time savings.

Comprehensive data at your fingertips

Sonyks is the first instrument with an onboard screen for GWT interpretation. It uses a combination of broadband and Full Matrix Capture (FMC) data collection, meaning that all data ever needed is collected once to make analysis possible anywhere. Move on to the next location knowing you have all the necessary data with increased speed and peace of mind.

Best instrument and tooling provide the best data

With an unmatched Signal-to-Noise Ratio (SNR), Sonyks inspects longer distances and locates even smaller defects. This improved SNR can dramatically simplify analysis and increase the overall efficiency of the inspection by 50%.

Ramp up your utilization rate

Sonyks is an incredibly versatile system that allows operators to address more applications thanks to short-range and medium-range capabilities in addition to long-range ultrasonic testing. For example, use the new 128 kHz magnetostrictive collar to inspect flanged pipes efficiently.

Sound evolution for GWT experts

Reuse transducer rings you already own and make the most of your past investment in GWT. Couple your existing collars to a new-generation instrument with best-in-class electronics and give a second life to your inspection programs.

Protect Your Investment. Maximize Uptime. Unlock More Value.

To help you succeed throughout the lifecycle of your equipment, Eddyfi Technologies offers the Customer Success Program (CSP), designed to reduce downtime, boost productivity, and protect your investment.

With varying levels of access tailored to your unique needs, the CSP provides a flexible suite of services including:

- Annual calibrations

- Accidental damage protection

- On-demand eLearning

- Collaborative support tools

- And more!

Whether you're looking for peace of mind, compliance support, or enhanced efficiency, the CSP strengthens our partnership and ensures you get the most from your Eddyfi solution.

Exclusive Content

Sonyks Demonstration

Safeguarding Industries: Pioneering Inspection Technologies for Industrial Sprinkler Systems

Check out this informative article shining a spotlight on guided wave testing equipment offered by Eddyfi Technologies.

Specifications

INSTRUMENT

355 × 288 × 127 mm (14.0 × 11.3 × 5.0 in)

7.2 kg (15.9 lb)

100–240 VAC, 50–60 Hz

Direct VAC or onboard batteries

10.8 V Li-ion, rechargeable, DOT compliant, How-swappable

6–8 hours

HDMI

40

5–260 kHz

200V, peak to peak

40

Up to 100 dB

365 m: longitudinal in pulse-echo or 200 m: torsional in pulse-echo

128

C-scan imaging, Time delay focussing

26.4 cm (10.4 in) Non reflective (AR coating) Anti-fingerprint (oleophobic coating) 3 mm (1/8 in), chemically strengthened glass cover Optically bonded LCD and touchscreen Passive backlight enhancement

Sonyks GO (Instrument) Sonyks PRO (Optional Laptop Control)

Optional connection through Wi-Fi or Gigabit Ethernet

200 GB, SSD

Sealed and internal fan

60 PSI maximum pressure

Yes

Accurate positioning to 2.5 m (8.2 ft)

Magnetostrictive and Piezo transducer compatibility

Sonyks Piezo and Magneto tools, Teletest and other commercial PZT rings

INSTRUMENT (SUITE)

Automatic with Sonyks tooling including ring type, size, serial number, pipe and angular orientation

125 ms

Onboard capacitance testing

TOOL AND MODULE TYPES COMPATIBILITY

Piezo Tooling

Piezoelectric transducers (PZT)

20–80 kHz broadband collection

15.2–91.4 cm (6–36 in) single collar 66–182.9 cm (26-72 in) dual collar setup

Automatic collar recognition, pipe size, orientation, and angular position

120˚C (248˚F)

Magneto Tooling

Segmented Magnetostrictive Sensors (SMS)

32 kHz – Test range 22–42 kHz 64 kHz – Test range 54–74 kHz 128 kHz – Test range 118–138 kHz

3.8, 5.1, 7.6 and 10.2 cm (1.5, 2, 3 and 4 in)

80˚C (176˚F) 120˚C (248˚F) short term

Teletest Tooling

Piezoelectric transducer

15.2–61 cm (6–24 in) single collar 66–132.1 cm(26–52 in) dual collar setup 137.2–198.1 cm(54–78 in) treble collar setup

20–80 kHz depending on spacing and wave mode

Standard 120˚C (248˚F) High Temperature (HT) 240˚C (464˚F)

Multimode 3 ring torsional – 30 mm (1.2 in) 3 ring torsional – 45 mm (1.8 in)