Eddyfi's First Portable System for AC and ECT Tubing Inspection

From: Tuesday, March 28, 2017

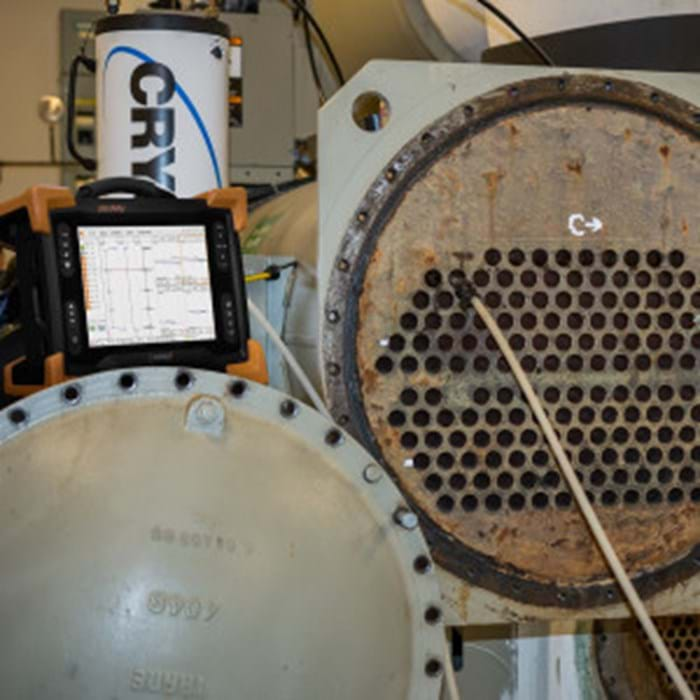

This new Reddy® eddy current testing (ECT) system is perfect for air conditioners and intended to replace aging solutions used in the inspection industry.

Committed to advanced NDT inspection technologies, Eddyfi is pleased to introduce a new addition to its Reddy line dedicated to AC and ECT tubing inspection. This new solution is designed to replace a wide range of existing aging ECT instruments used to inspect air conditioners and to perform other ECT tubing inspections. Most existing ECT instruments are bulky and have not evolved since their introduction, making them incompatible with modern realities where productivity and profitability are crucial.

The new Reddy supports all currently available AC and ECT probes without the need for adapters or reference probes to balance the absolute channel. Because air conditioners are similar to small heat exchangers (HX) in terms of number of tubes, for example, portability and minimal setup time are essential. Reddy is roughly 30 % lighter than the most widespread instruments currently in the field, and it features probe plug-and-play capabilities, an intuitive setup wizard, and a tube list creator for increased productivity.

The system is battery-operated, sealed, and water resistant—unique features for this type of equipment. Reddy also features a large integrated display and analysis software for on-the-fly reporting.

Finally, Reddy has configurable recording sequences, which enable automatic acquisitions, and it is compatible with prevalent tubesheet mapping and reporting software.

“There was an urgent need for this new solution in the air-conditioner market,” says Olivier Lavoie, tubing product manager. “Testers currently available on the market are cumbersome, need adaptors and power supplies, and offer no data-recording or reporting capabilities. We wanted to raise the bar with this latest Reddy by offering a modern, easy-to-use portable solution that would significantly improve productivity. We’re confident this will prove to be a game changer for the industry.”

Since data acquired on-the-fly with Reddy is recorded, there is no more need for note-taking—it is on-the-spot acquisition and data management; the best of both worlds. Further, the system completely does away with hand-written reports: when an inspection is complete, reports can be generated in a single click—complete with screenshots of detected defects—signed, and handed to customers.

For details about Reddy, visit www.eddyfi.com/reddy-for-tubing-inspection/.

About Eddyfi Technologies

Eddyfi Technologies is a label designed to maximize the potential of multiple advanced and niche NDT inspection technology brands. With its two centers of excellence in Québec (Canada) and Swansea (UK), Eddyfi Technologies focuses on offering high-performance NDT solutions for the inspection of critical components and assets through two strong, complementary brands: Eddyfi and Silverwing. The company has more than 200 employees, six offices around the globe all staffed with NDT experts, and serves customers in more than 65 countries in such major industries as nuclear, power generation, oil & gas, and aerospace.