Eddyfi has a Sharck Probe for SCC Detection and Measurement

From: Wednesday, May 10, 2017

Eddyfi releases a high-resolution model of its field-proven Sharck™ probe for the direct assessment of stress-corrosion cracking in pipeline integrity applications.

Eddyfi, a world leader in electromagnetic inspection technologies, is proud to introduce a solution specifically intended for the in-ditch direct assessment of stress-corrosion cracking (SCCDA) in pipelines. As its other namesakes, this high-resolution probe uses tangential eddy current array (TECA™) technology and is designed for the detection and depth measurement of surface-breaking cracks in carbon steel.

Stress-corrosion cracking (SCC) is the result of stress and a corrosive environment on metal, therefore common on the external surface of carbon steel pipelines in contact with corrosive soil. Because of the nature of SCC colonies (surface-breaking cracks in the form of shallow, extremely fine branches) found on pipelines, they are challenging to detect and size (especially the depth) with traditional non-destructive testing (NDT) techniques.

Current inspection techniques used in assessing SCC have several limitations addressed by the high-resolution Sharck probe. Detecting SCC is usually performed with magnetic particle testing (MP) or dye-penetrant inspection (DPI), which is time consuming, hard to deploy in some weather conditions, and requires extensive surface preparation. Once detected, ultrasonic testing (UT) is used to determine the depth of individual cracks within an SCC cluster—a highly challenging and operator-dependent task, especially where multifaceted, shallow cracks in various orientations are involved.

The high-resolution Sharck probe was designed to detect cracks as shallow as 0.25 mm (0.010 in) and as short as 2 mm (0.080 in), as well as to accurately size cracks as deep as 3 mm (0.120 in). Further, the probe has a flexible inspection interface offering a wide coverage of 71 mm (2.8 in) compatible with pipes 254–1220 mm (10–48 in) in diameter. Finally, to take into account the most common coatings and paints applied to pipeline surfaces, the new Sharck probe can tolerate coating thicknesses up to 2 mm (0.08 in), removing the need for pre and post-inspection surface preparation.

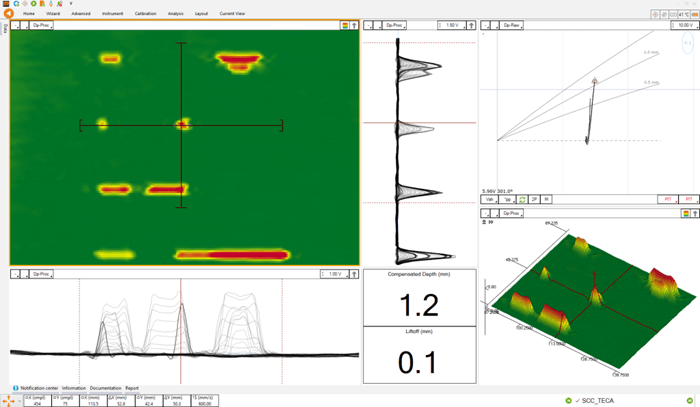

Capable of scanning at speeds up to 600 mm/s (2 ft/s), the probe has a robust design. Its built-in encoder enables accurately positioning defects and measuring their length directly from scan results, through the use of 2D and 3D C-scans. Depth values are automatically extracted for rapid assessment.

“We are very proud of this latest addition to the Sharck family. The high-resolution Sharck probe was designed to offer a better solution to the SCCDA market. Its design and real-time digital mapping enable users to detect and size defects with assurance and repeatability. The solution is meant to offer an alternative to the traditional combination of two methods for SCC detection and depth measurement. Finally, the probe fully complies with the NACE SP0204 standard practice,” said Angélique Raude, surface inspection product manager at Eddyfi.

For more on the high-resolution Sharck, visit goo.gl/zDPLkJ.

About Eddyfi Technologies

Eddyfi Technologies is a label designed to maximize the potential of multiple advanced and niche NDT inspection technology brands. With its two centers of excellence in Québec (Canada) and Swansea (UK), Eddyfi Technologies focuses on offering high-performance NDT solutions for the inspection of critical components and assets through two strong, complementary brands: Eddyfi and Silverwing. The company has more than 200 employees, six offices around the globe all staffed with NDT experts, and serves customers in more than 65 countries in such major industries as nuclear, power generation, oil & gas, and aerospace.